High depth-to-width ratio nanofiber structure based on mechanical stretching and preparation method of high depth-to-width ratio nanofiber structure

A nanofiber and mechanical stretching technology, applied in nanotechnology and other directions, can solve the problems of difficult to achieve orientation, localized manufacturing, and difficult to achieve nanofiber array preparation, and achieve the effect of simple process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

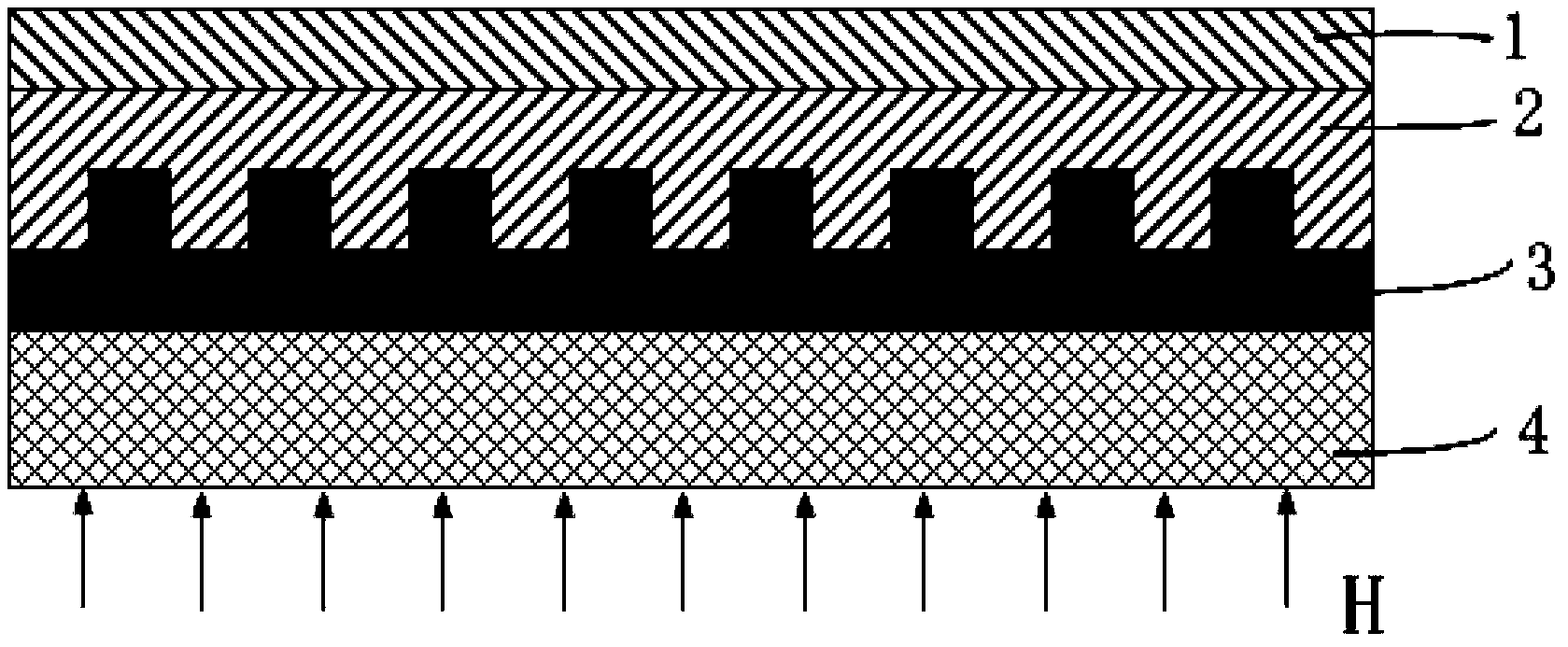

[0039] The present invention will be further described below by accompanying drawing and concrete implementation example:

[0040] The present invention is a method for preparing a nanofibrous structure with a large aspect ratio based on mechanical force stretching, comprising the following steps:

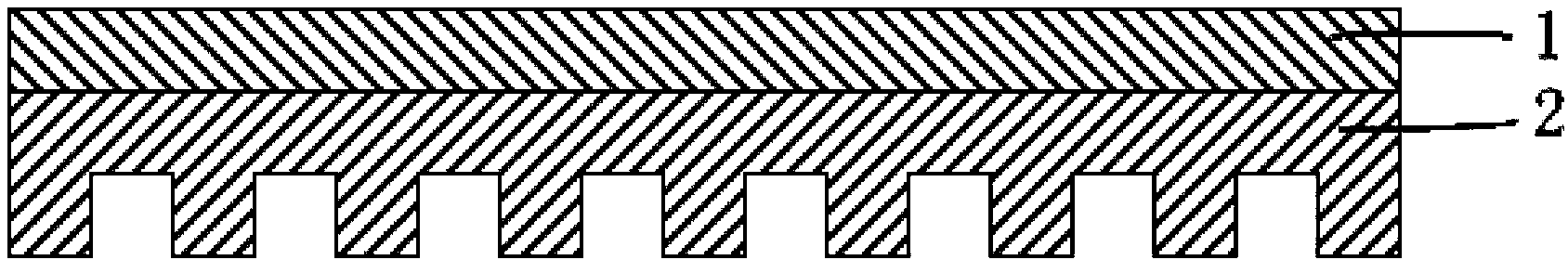

[0041] 1) if figure 1 As shown, the flexible hole array mold 2 is prepared by the replica method, and the flexible hole array mold 2 is adsorbed on the lower surface of the upper plane 7 of the mechanical table through the mold backing 1; wherein, the specific method for preparing the flexible hole array mold 2 is as follows:

[0042] Firstly, the silicon mold of the cylindrical array is prepared on the silicon substrate by photolithography and plasma etching, and then the flexible hole array mold 2 complementary to the structure of the silicon mold is obtained by the replica method; the flexible hole array mold 2 is A PDMS or fluororesin flexible mold capable of maintaining good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com