Self-cleaning submerged tubular membrane bioreactor

A biological reaction device and tubular membrane technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as reducing system operating efficiency and affecting continuous operation of the system, achieving Avoid complex operation process, low power consumption, low transmembrane pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

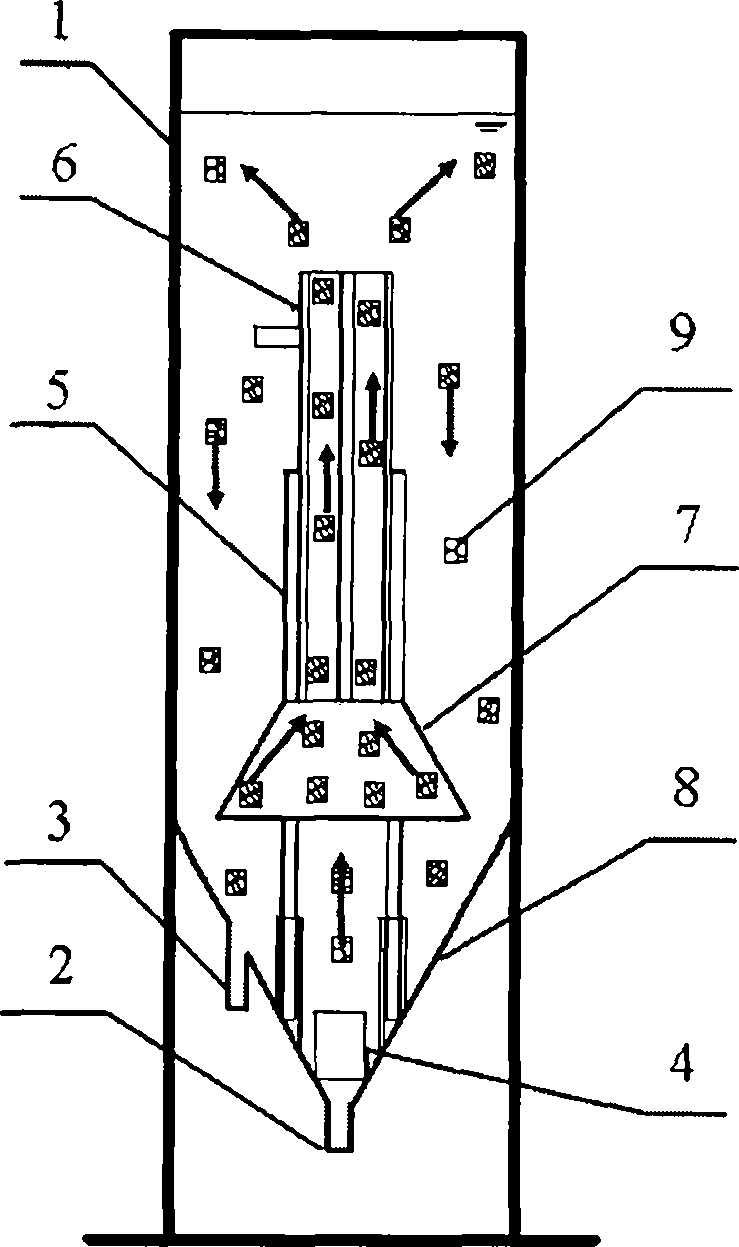

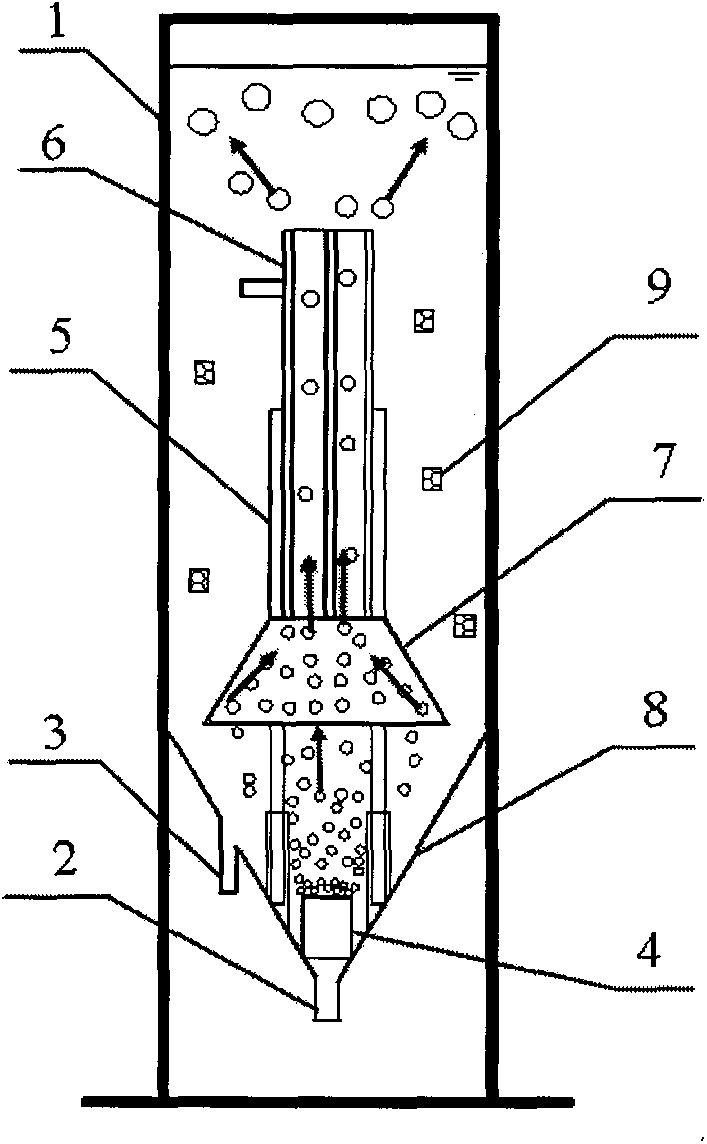

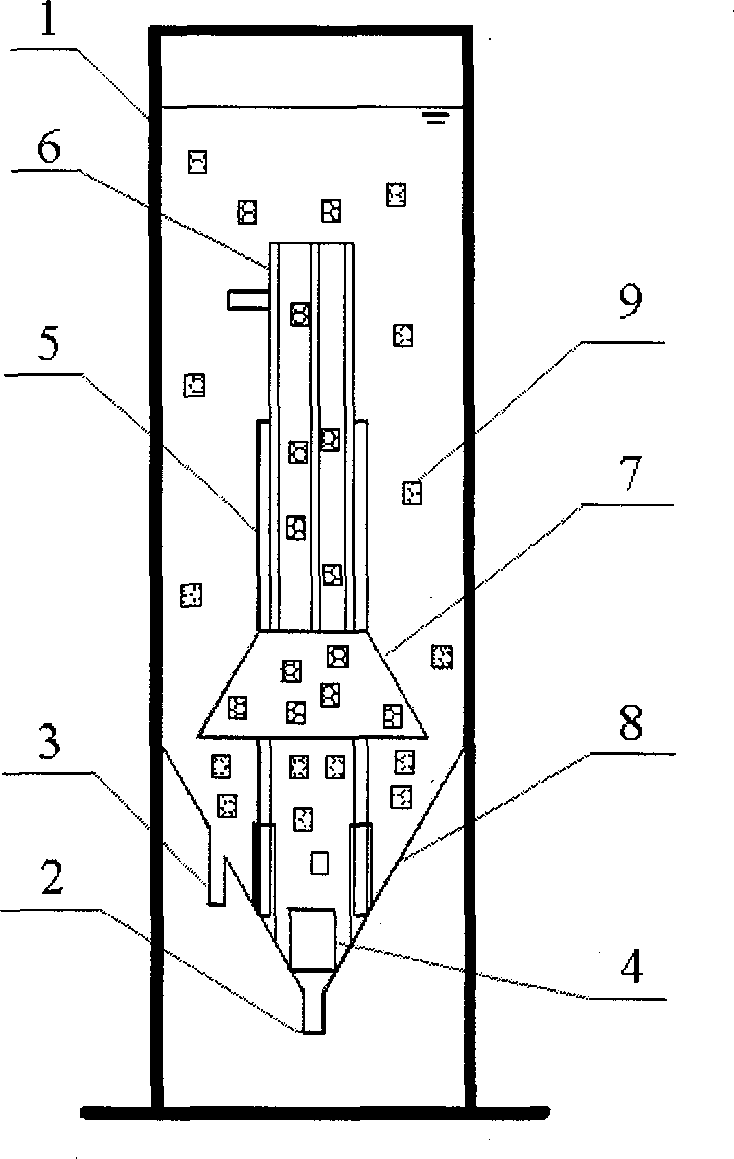

[0020] see figure 1 , The MBR device provided by the present invention is a self-cleaning submerged tubular membrane bioreactor, which consists of: a housing 1, a water inlet 2, a mud discharge port 3, a gas disperser 4, a bracket 5, and a tubular membrane module 6 , a diversion cover 7, a carrier collector 8, and a particle carrier 9; wherein: the bottom of the device is a carrier collector 8, which is provided with a water inlet 2 and a mud discharge port 3, and a gas diffuser 4 is installed above the water inlet 2. The tube-type membrane module 6 is fixed above the gas diffuser 4 through the bracket 5 in the device, and the guide cover 7 is installed under the tube-type membrane module 6 . In the submerged tubular membrane bioreactor of the present invention, a particle carrier 9 is added, the carrier is a macroporo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com