Lacing hole boss structure of turbine blade and matching structure for lacing hole boss structure and loose lacing wires

A steam turbine blade and boss structure technology, which is applied in the direction of blade support components, mechanical equipment, engine components, etc., can solve the problems of local wear of tie bars, poor damping effect, stuck holes of tie bars, etc., and achieve the alleviation of wear problems , The installation process is smooth, and the effect of reducing torsional vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

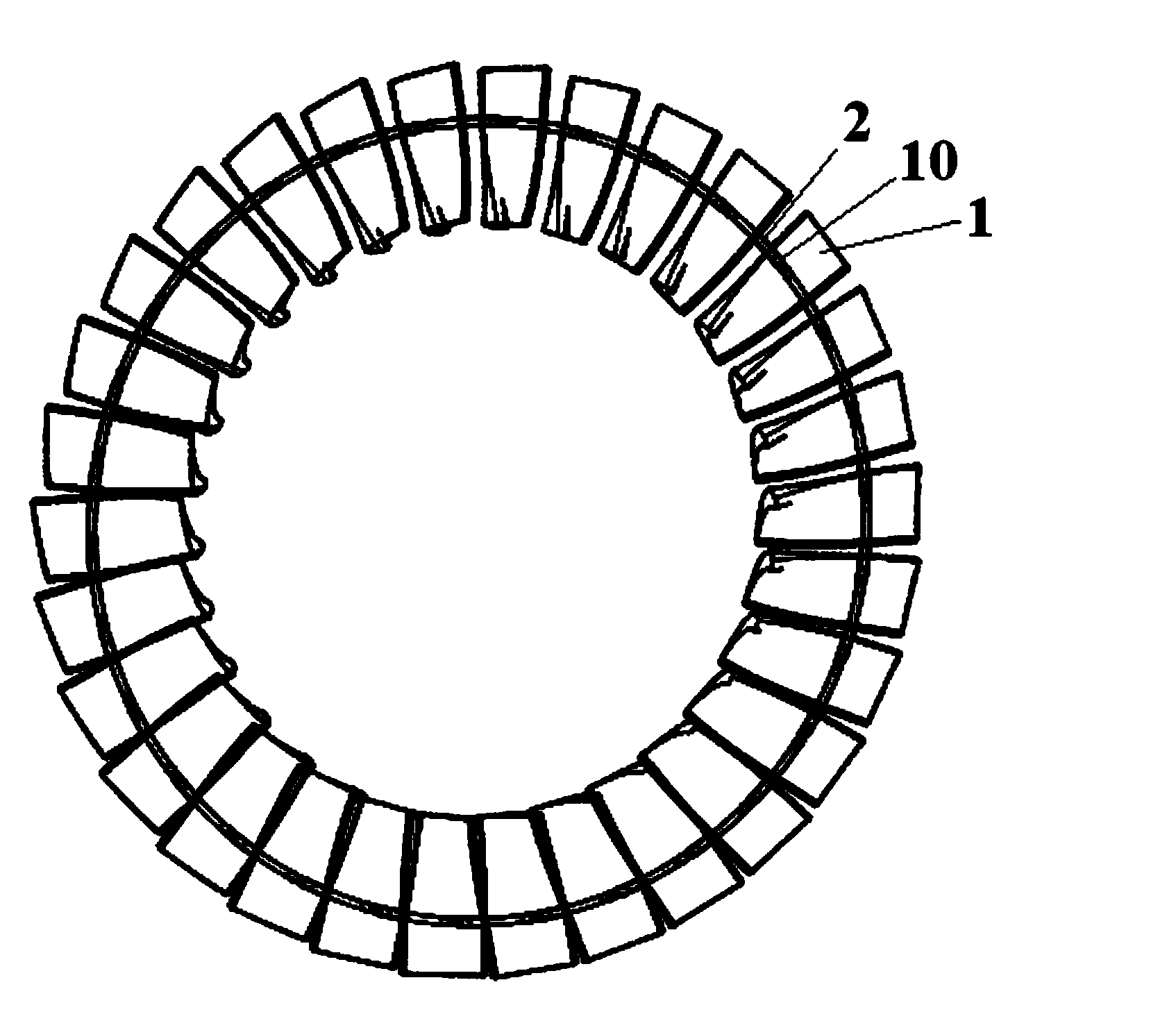

[0030] see figure 1 60%-80% of the blade height of the steam turbine motor blade 1 is a tie hole 10, and the loose tie 2 passes through the tie hole to connect the blades in a full circle.

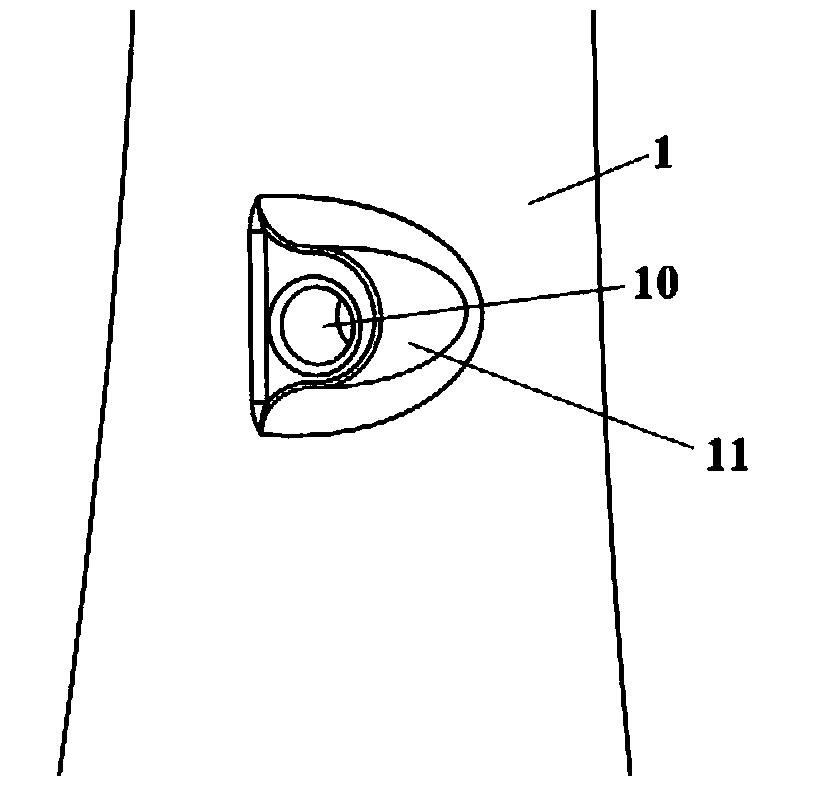

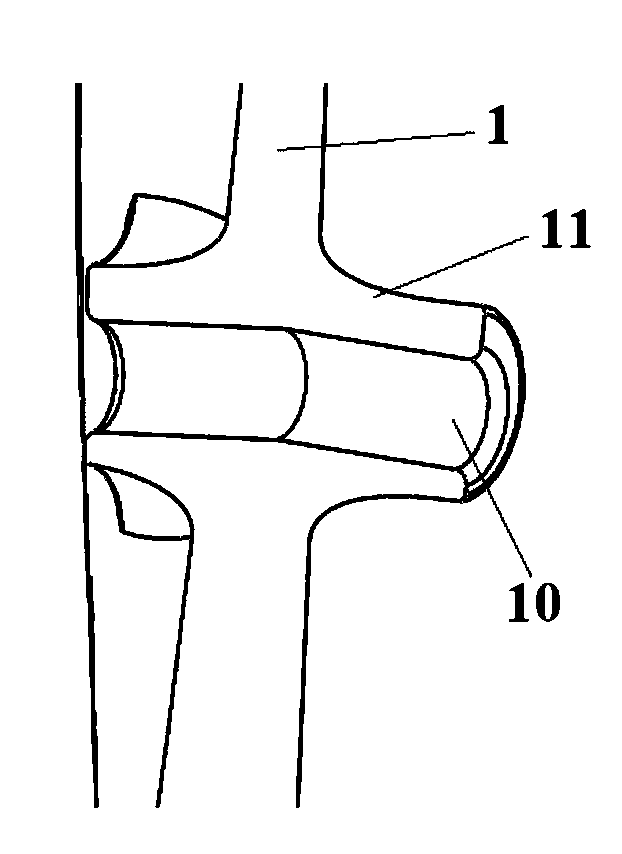

[0031] see Figure 2a , as shown in 2b, a boss structure of a steam turbine blade tension hole of the present invention, a boss is processed on the pressure side and the suction side of the blade 1, the boss 11 is horizontally extended, and its axis 110 is the circumference of the blade 1 In the direction, the sum of the protruding lengths of the pressure surface and the suction surface boss 11 of adjacent blades 1 is preferably 0.4-0.6 times the blade pitch. A tie hole 10 is arranged in the boss 11 so that the tie bar 2 penetrates, and the relative angle between the center line 100 of the tie hole and the center line 110 of the boss is shown in Figure 2c , taking the pitch circle diameter of the tie bar 2 as the standard, the tie bar hole 10 is inclined to both sides, and forms an angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com