High-sensitivity diaphragm type photoacoustic spectrum sensor based on self-mixing

A high-sensitivity, photoacoustic spectrum technology, applied in the field of high-sensitivity diaphragm-type photoacoustic spectrum sensors, can solve the problems of fiber laser laser self-mixing interference principle without the application of photoacoustic spectrum sensing device, etc., to ensure large dynamic range response The effect of high sensitivity measurement, high coupling efficiency, and simple coupling method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

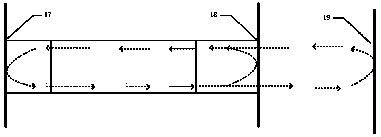

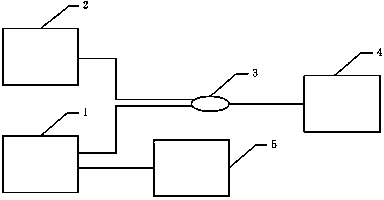

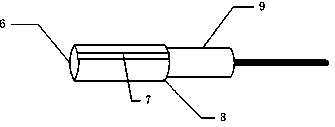

[0030] Figure 1 to Figure 7 , including sensing light source 1, excitation light source 2, first coupler 3, photoacoustic cavity 4, signal processing circuit unit 5, high-sensitivity diaphragm 6, gas window 7, ceramic sleeve 8, ceramic ferrule 9, pump Pu unit 10, wavelength division multiplexer 11, fiber grating 12, gain medium 13, one-way isolator 14, circulator 15, second coupler 16, laser front end face 17, laser rear end face 18, target object scattering end face 19 Wait.

[0031] Such as figure 2 As shown, the present invention is a high-sensitivity diaphragm photoacoustic spectrum sensor based on self-mixing, including a sensing light source 1, an excitation light source 2, a first coupler 3, a photoacoustic cavity 4, and a signal processing circuit unit 5. The laser light emitted by the sensing light source 1 and the excitation lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com