Method for determining hydrogen absorption/desorption thermodynamic parameter of hydrogen storage alloy

A technology of hydrogen storage alloy and thermodynamics, which is applied in the direction of testing metals, instruments, and material inspection products. It can solve the problems of low reliability, inability to realize automatic computer analysis, and large workload in the analysis process, so as to improve accuracy and reliability. , Improve efficiency and ensure intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

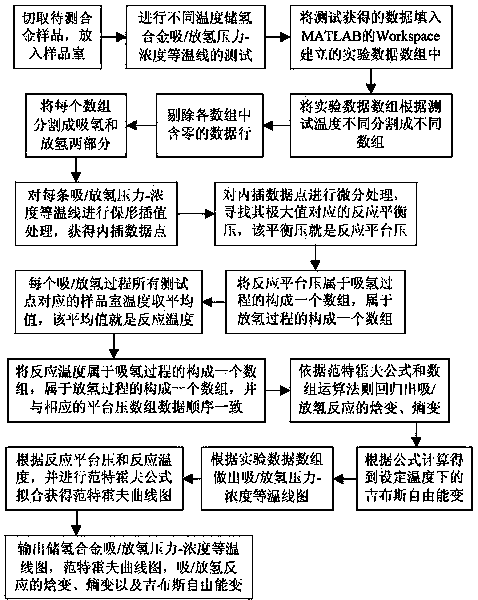

Method used

Image

Examples

Embodiment

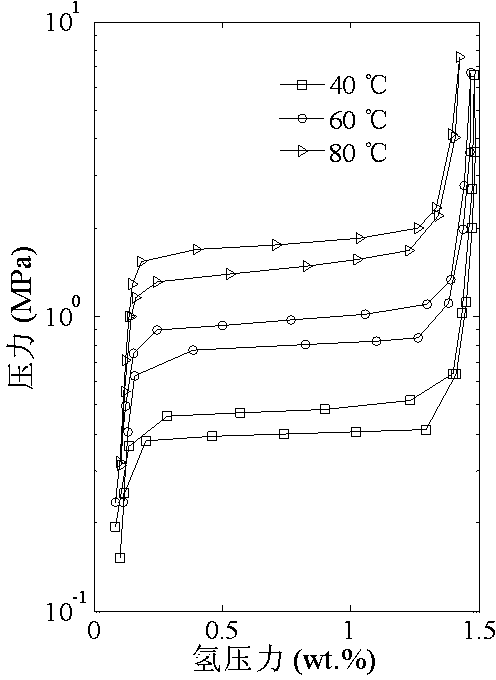

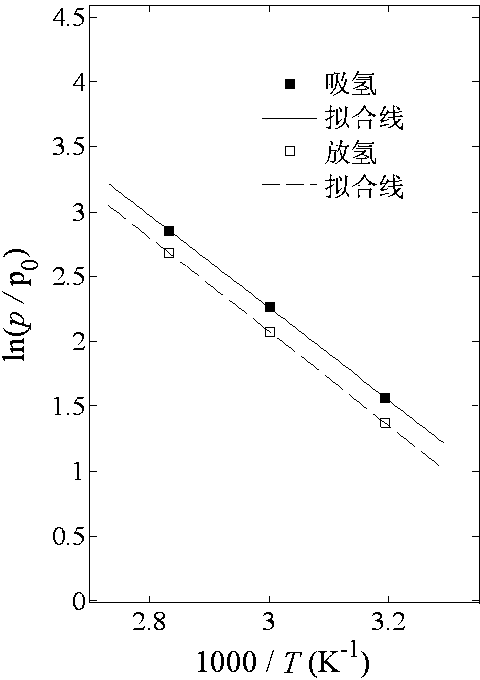

[0049] Preparation of Hydrogen Storage Alloy LaNi 5 , the raw material metals are La 99 wt%, Ni 99.9 wt%, using vacuum induction melting under the protection of argon, after melting, put the alloy into a quartz tube with a vacuum degree of 1 Pa for annealing, and keep it at 1000 ℃ for 6 After h, quickly quenched into water. Annealed samples were chemically analyzed to verify compositional accuracy. Finally, weigh about 1g of the sample and put it into the sample chamber of the hydrogen storage alloy hydrogen absorption and desorption performance tester, and carry out the hydrogen absorption / desorption pressure-concentration isotherm at 40°C, 60°C and 80°C in the environment of a constant temperature water bath test. The test obtained the data in Table 1, Table 2 and Table 3 below. Then open the MATLAB software to create an array named PCT in the Workspace window, copy the measured isotherm data into the PCT array, and determine the calculated temperature of Gibbs free energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com