Semiconductor material parameter tester and test method based on surface photovoltage method

A technology of surface photovoltage and material parameters, which is applied in the direction of single semiconductor device testing, etc., can solve problems such as surface damage, manpower consumption, material and power, and silicon wafer damage, so as to reduce the influence of grain boundary effects, stabilize and accurate measurement results, and avoid The effect of being destroyed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

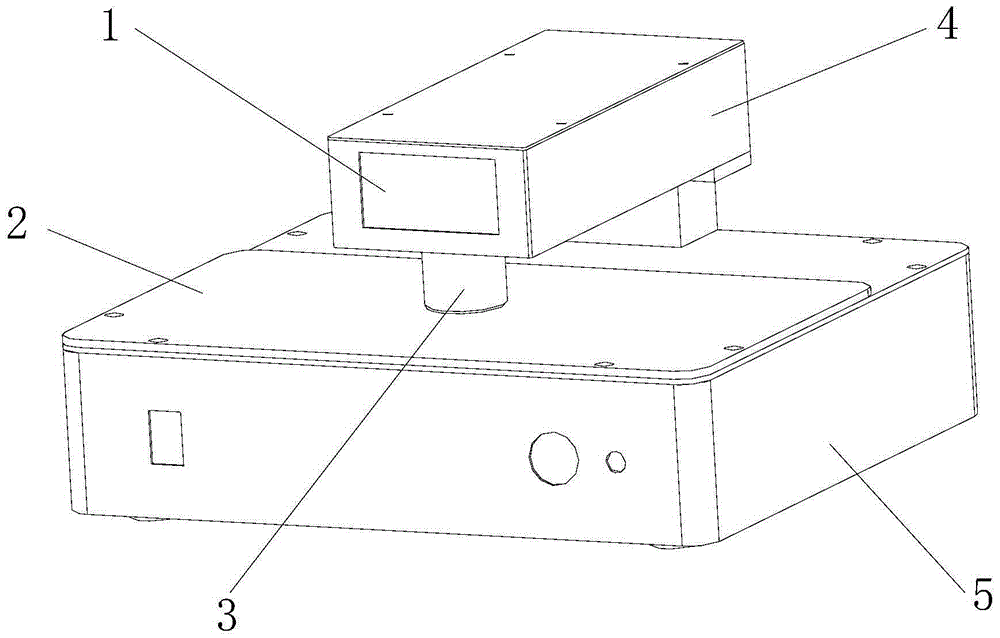

[0035] Such as figure 1 As shown, the semiconductor material parameter tester based on the surface photovoltage method in this embodiment includes a liquid crystal display 1 , a sample stage 2 , a measuring probe 3 , a cantilever 4 , and a box 5 . Among them, the sample table 2 and the cantilever 4 are set on the top of the box body 5, the measuring probe 3 and the liquid crystal display 1 are set on the cantilever 4, the center of the measuring probe 3 is aligned with the center of the sample table 2, and there is a certain gap in the middle for placing Sample to be tested.

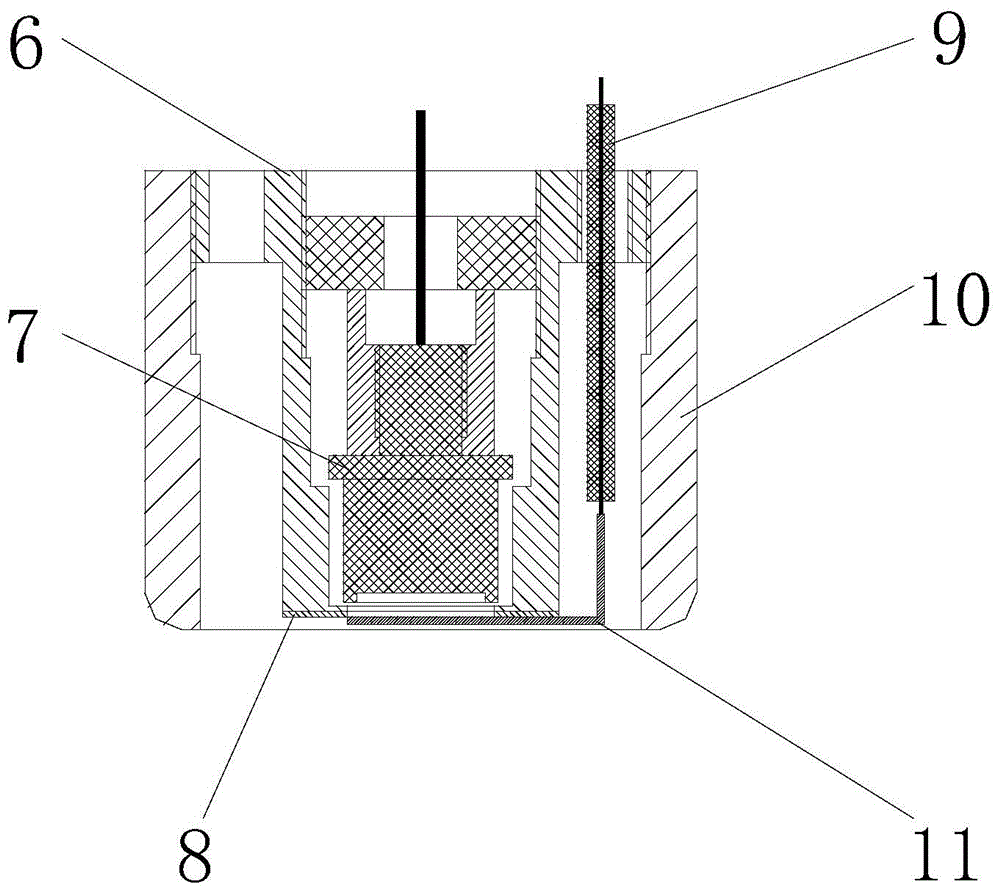

[0036] Such as figure 2As shown, the measuring probe 3 includes an aluminum alloy sleeve 6 , an infrared laser 7 , a shielding film 8 , a coaxial cable 9 , an aluminum alloy shell 10 , and an induction electrode sheet 11 . The infrared laser 7 is placed in the aluminum alloy sleeve 6, and the two are separated by a thin layer of gasket. There is a round hole on the top of the aluminum alloy sleeve 6 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com