A composite graphite grounding conductor, its preparation method and its application method

A grounding conductor, composite graphite technology, applied in the direction of connection, connection contact material, electrical components, etc., can solve the problems of low mechanical strength, poor conductivity, easy damage, etc., and achieve high mechanical strength, high conductivity, and not easy to break. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

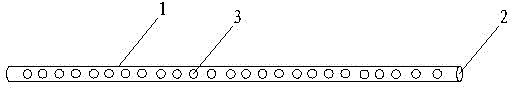

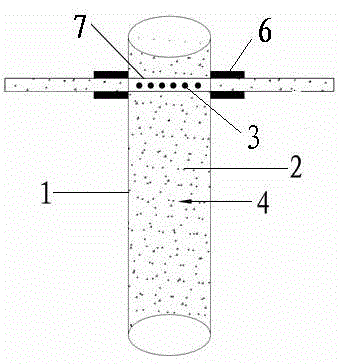

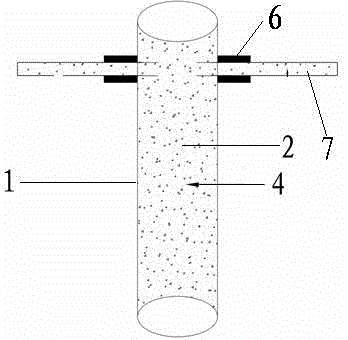

[0034] see Figure 1-Figure 5 , the invention includes a corrosion-resistant casing, the casing is filled with a high-carbon graphite inner core, and a group of through holes are distributed on the casing.

[0035] The sleeve is cylindrical.

[0036] The casing is a hot-dip galvanized pipe or a stainless steel pipe.

[0037] The diameter and wall thickness of the casing of the present invention can be designed according to actual needs, for example, the diameter of the casing can be 5-10 mm, and the wall thickness of the casing can be 2-4 mm.

[0038] The through holes are evenly arranged on the sleeve.

[0039] A method for preparing a composite graphite grounding conductor, comprising the steps of:

[0040] (1) High-purity expanded graphite is used as raw material;

[0041] (2) Choose a high-strength adhesive as the adhesive; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com