Rabbit breeding device

A technology of breeding cages and moving hoppers, which is applied in the field of rabbit breeding devices, can solve the problems of low breeding costs, high labor intensity, and the inability to guarantee the best conditions for raising and breeding rabbits, and achieve the effect of reducing the amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

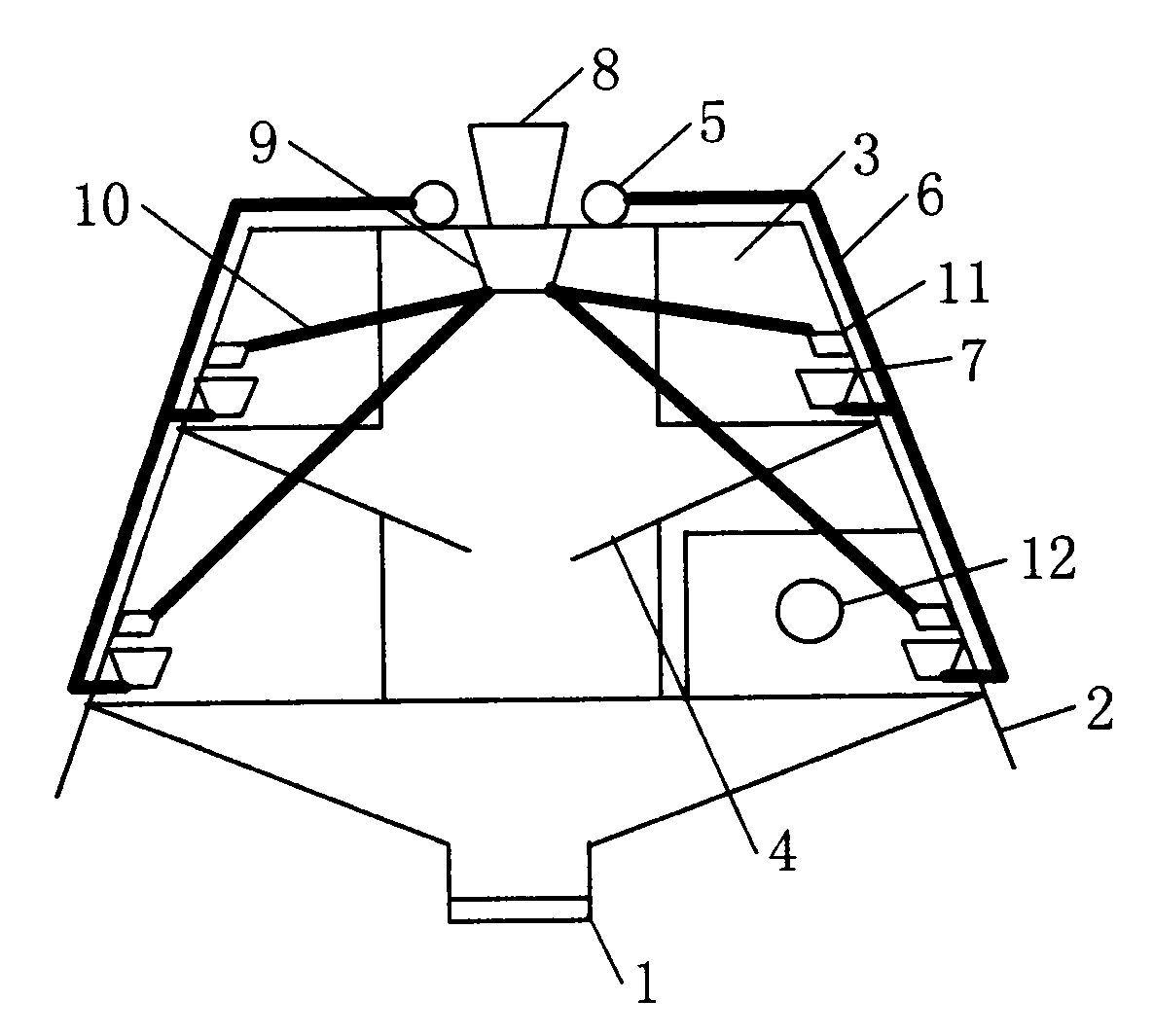

[0020] As shown in the figure, a culture cage 3 is relatively layered and fixed on the cage frame 2, and a water supply main pipe 5 and a mobile hopper 8 are arranged on the uppermost layer of the culture cage;

[0021] The water supply main pipe is communicated with the water feeding tank 7 arranged in the culture cage by the water supply pipe 6, and the water supply pipe is equipped with a solenoid valve;

[0022] The running track of the mobile hopper is placed on the cage, and a motor and a reducer are installed on the mobile hopper. The lower part of the mobile hopper is equipped with a walking wheel, and the motor is connected to the power supply through a cable; Feed trough communicates with the feeding trough 11 that is arranged in the breeding cage respectively by distributing pipe 10;

[0023] The lower part of the breeding cage is provided with a sloping plate for connecting feces and urine, and its lower end is relatively placed in the middle of the breeding cages ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com