Automatic unloading device used for aluminium pig production

An automatic unloading device and aluminum ingot technology, applied in pig iron casting workshops, manufacturing tools, casting workshops, etc., can solve the problems of low work efficiency of manual ingot removal and high labor intensity of staff, so as to improve work efficiency and reduce labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

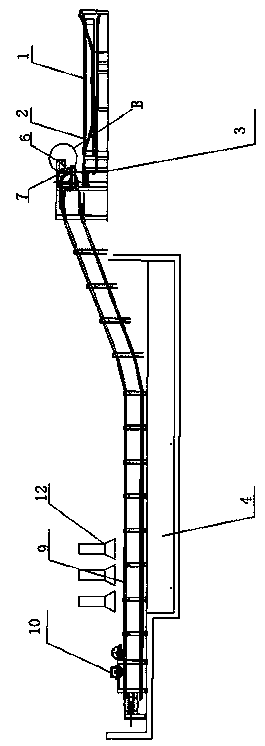

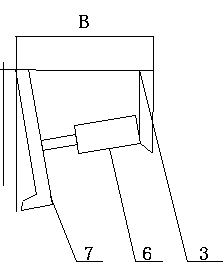

[0012] Depend on figure 1 It can be seen from the schematic diagram shown that the automatic unloading device for aluminum ingot production of the present invention mainly includes a conveyor belt, a cylinder 6, an ingot casting machine 10, a demoulding claw 7 and a demoulding support 3.

[0013] The conveyor belt includes an aluminum ingot forming conveyor belt 9 and an aluminum ingot finished product conveyor belt 2, and the aluminum ingot forming conveyor belt 9 and the aluminum ingot finished product conveyor belt 2 are arranged in sequence, on the side of the aluminum ingot forming conveyor belt 9 away from the aluminum ingot finished product conveyor belt 2 An ingot casting machine 10 is arranged on the upper side, and the side of the aluminum ingot forming conveyor belt 9 close to the finished aluminum ingot conveyor belt 2 is gradually inclined upward. below.

[0014] A plurality of aluminum ingot molds 8 are evenly arranged on the aluminum ingot forming conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com