Grating punching machine

A punching machine and grating technology, applied in metal processing, etc., can solve the problems of unstable stamping process, low product qualification rate, high stamping cost, etc., and achieve the effects of high qualification rate, reduced production cost, and low stamping cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

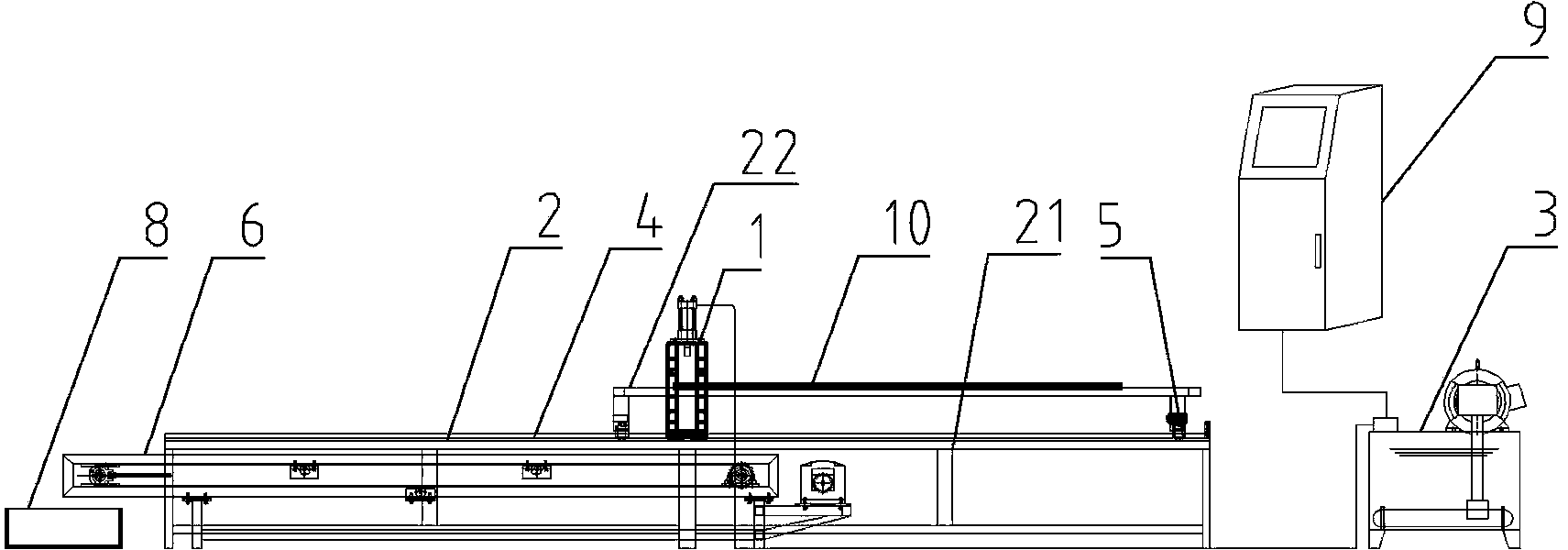

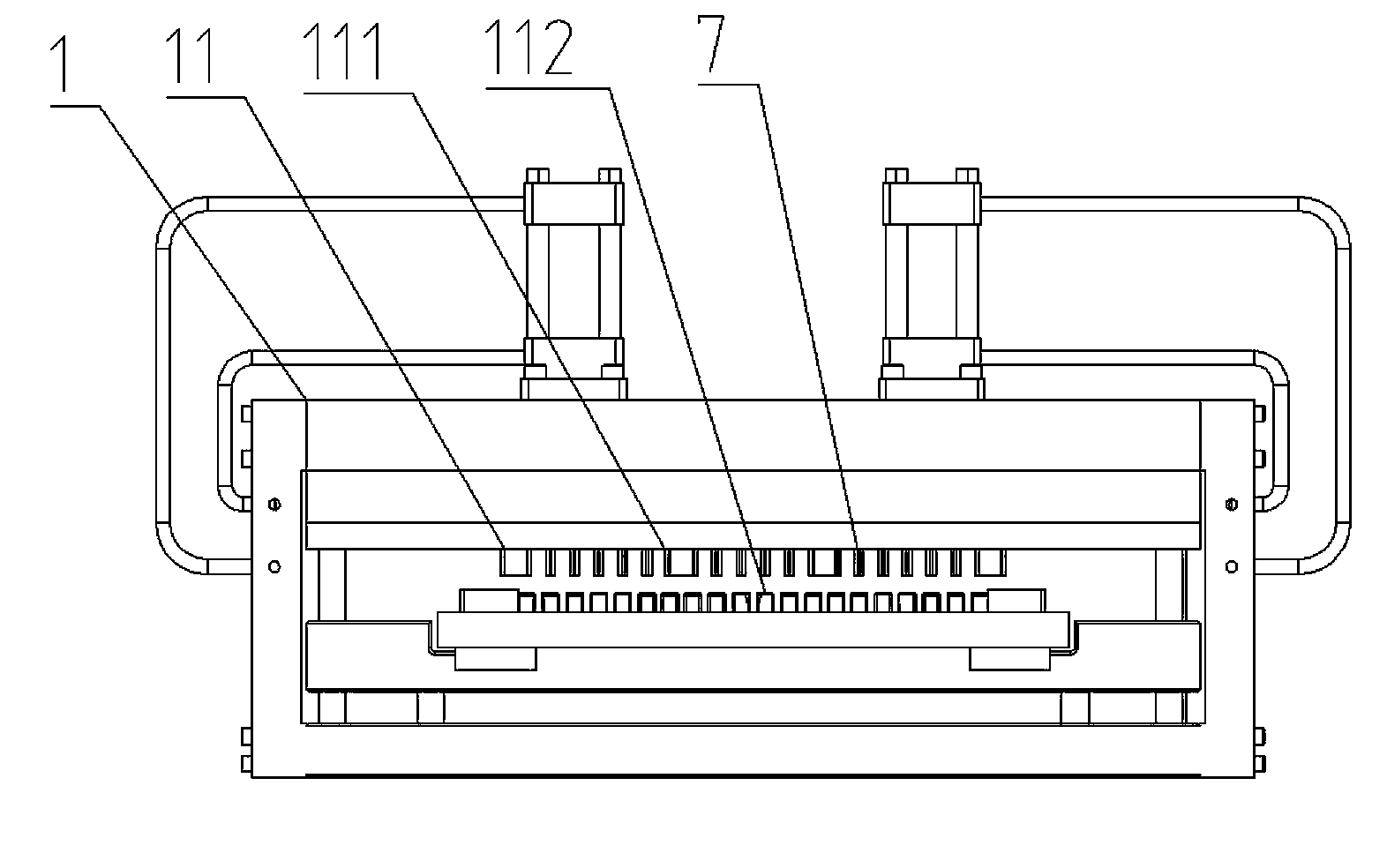

[0014] as attached figure 1 , 2 As shown, the present invention provides a grid punching machine, including a punching device 1 and a punching machine 2, the punching device 1 includes a punch 11, the punching device 1 is connected to a hydraulic workstation 3, and is fixedly installed on the punching machine 2, and the punching machine 2 includes Frame 21 and feed platform 22, frame 21 is provided with guide rail 4, is provided with roller 5 on the feed platform 22, and roller 5 cooperates with guide rail 4; The bottom of guide rail 4 is provided with conveyer belt 6, and conveyer belt 6 one end is installed on Below the punch 11, the other end stretches out from the frame 21; the punch 11 includes a punch group 111 and a stripping sleeve 112, and each punch group 111 includes a plurality of punch blocks 7, and the punch block 7 and the stripping sleeve 112 match.

[0015] As an optimized implementation, the above-mentioned punch group 111 includes more than two punch block...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap