Device and method for denitrification and dephosphorization by using industrial solid wastes

A technology for solid waste, nitrogen and phosphorus removal, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Promote the application value, the effect is remarkable, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Treatment of domestic sewage in a certain rural area

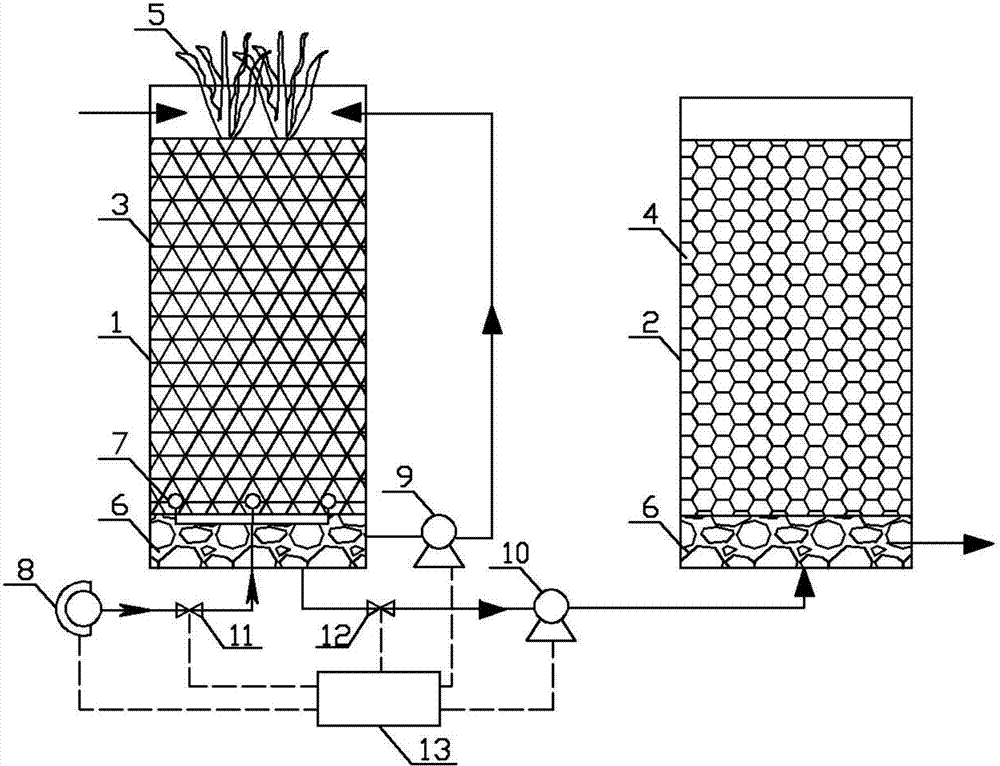

[0033] Such as figure 1 , the primary device 1 is cylindrical with a height of 1.6m, a diameter of 1.2m, a filter material layer height of 1.5m, and an effective volume of 1.7m3. The device reaction filter material 3 selects dehydrated aluminum sludge and light-burned magnesia, both of which come from a waterworks and a magnesia production plant respectively. The plant layer 5 is planted on the upper part of the first-level device 1, and the species is Diaolum sativa; the second-level device 2 It is cylindrical and has the same size and structure as the first-level device 1. The reaction filter material 4 of the second-level device uses acid neutralization residue and light-burned magnesia, which are respectively from an ilmenite factory and a magnesia production plant; the first-level device The bottom of 1 and the bottom of secondary device 2 are connected by laying pipelines, and the pipeline is provi...

Embodiment 2

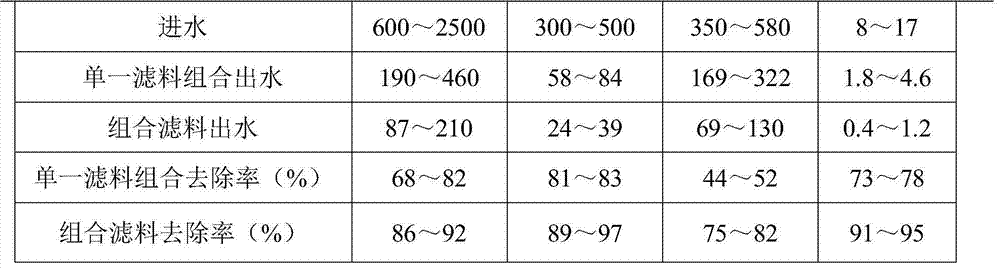

[0039] Embodiment 2: a certain farm waste water is processed

[0040] Such as figure 1 , the primary device 1 is a cube with a height of 1.5m, a length of 1.0m, a width of 0.7m, a filter material layer height of 1.4m, and an effective volume of 1.0m 3 , the heights of 3 layers of reaction filter material and 6 layers of pebbles in the first-level device are 1.3m and 10cm respectively, and the reaction filter material 3 of the first-level device is made of dehydrated aluminum sludge and red sand, which come from a waterworks and an alumina refinery respectively , and add the same quality, the plant layer 5 is planted on the top of the first-level device 1, and the variety is reed; the second-level device 2 is a cube and the size structure is the same as that of the first-level device 1, and the reaction filter material 4 of the second-level device is selected for use. The mud pellets come from an ilmenite plant and an alumina refinery respectively, and the added quality is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com