Method for producing propylene oxide

A propylene oxide and propylene technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of poor heat transfer effect, flying temperature of catalyst layer, shortened service life of catalyst, etc., to prevent overheating damage , The effect of reducing flying temperature and fast heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

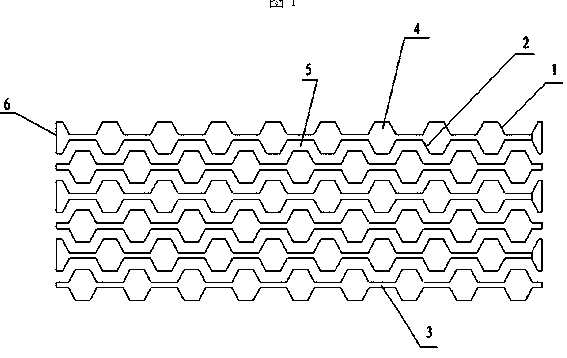

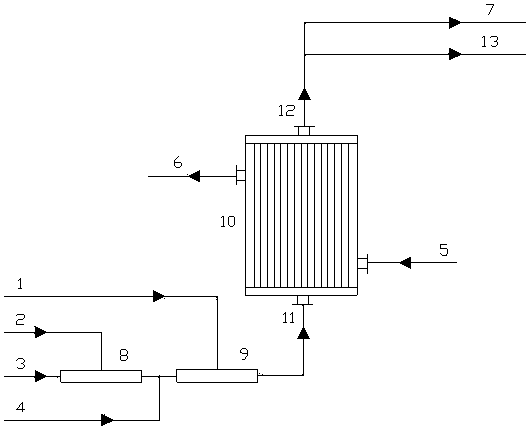

[0027] The production scale of HPPO is 100,000 tons / year, using titanium silicon molecular sieve catalyst, TiO 2 : SiO 2 It is 1:7. In the plate-type catalytic reactor, the molar ratio of propylene, hydrogen peroxide, additives, and methanol is 2:1:2:10 and flows through the plates filled with catalyst for sufficient reaction. The auxiliary agent is lithium chloride. A plurality of heat transfer plates are arranged side by side at fixed intervals inside the reactor, and the concave and convex surfaces of the corrugated plates of two adjacent heat transfer plates are arranged opposite to each other to form a group of heat transfer plates. The inner space formed by this group of heat transfer plates As a catalyst filling space, the gap channel formed between this group of heat transfer plates and another adjacent group of heat transfer plates serves as a heat transfer medium circulation space, and the adjacent two groups of heat transfer plates are arranged alternately. The c...

Embodiment 2

[0030] According to the method of embodiment 1, the HPPO production scale is 200,000 tons / year, adopts titanium silicon molecular sieve catalyst, TiO 2 : SiO 2 The ratio is 1:10, and the additive is sodium nitrate. The molar ratio of propylene, hydrogen peroxide, additives, and methanol is 2:1:2:10, the reaction pressure of the plate catalytic reactor is 1.1MPa in gauge pressure, the reaction temperature of the catalytic reactor is 55°C, and the total heat transfer of the reaction Factor K from the original 300 w / m 2 k increased to 1200 w / m 2 k, the average service life of the catalyst was extended to 3.9 years.

[0031]

Embodiment 3

[0033] According to the method for embodiment 2, the TiO of titanium silicon molecular sieve catalyst 2 : SiO 2 The ratio is 1:20, and the auxiliary agent is potassium sulfate. The molar ratio of propylene, hydrogen peroxide, additives, and methanol is 2:1:2:10, the reaction pressure of the plate catalytic reactor is 3.0MPa in gauge pressure, the reaction temperature of the catalytic reactor is 80°C, and the total heat transfer of the reaction Factor K from the original 400 w / m 2 k increased to 1500 w / m 2 k, the average service life of the catalyst was extended to 4.0 years.

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com