Grinding coupling method for preparing disperse dye

A technology of disperse dyes and dispersants, which is applied in the coupling reaction of azo dyes, azo dyes, organic dyes, etc. It can solve the problems of high acid or alkali consumption for dissolution, high energy consumption for low-temperature coupling, and high water consumption for dye synthesis, etc. problems, to achieve the effect of saving grinding time, increasing production and saving material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

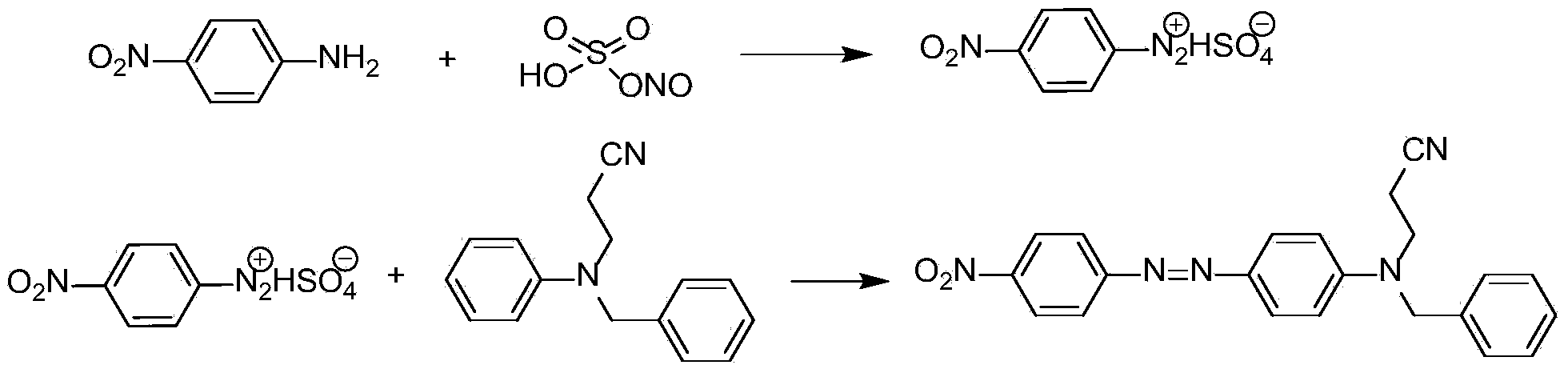

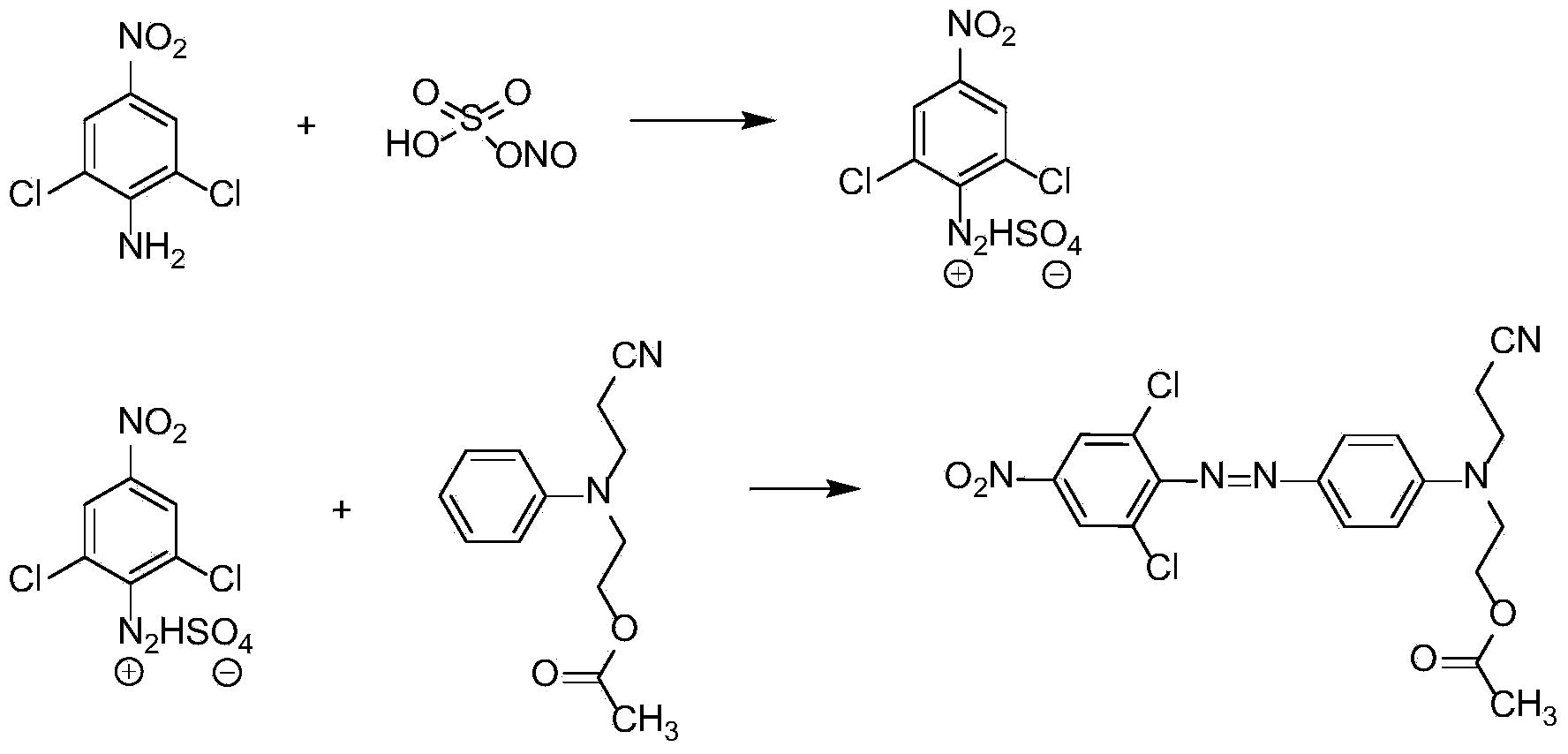

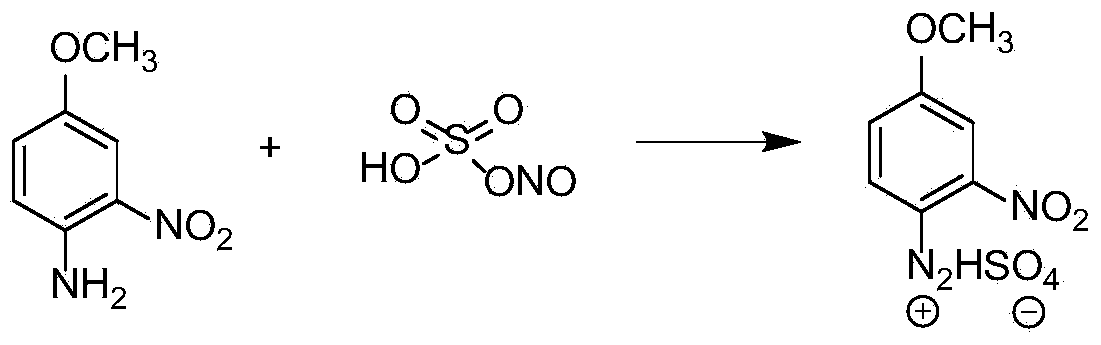

Method used

Image

Examples

Embodiment 1

[0024] Add 68.0 g of industrial nitrosyl sulfuric acid with a content of 40% in a 250 ml three-necked flask. Control the temperature in the bottle at 35°C-45°C and gradually add 28.2g of p-nitroaniline (content 98.0%, 0.2mol). After the addition, keep stirring at 35°C-45°C for 3 hours and let stand for 6 hours. Use a glass rod to dip a few drops of diazonium solution into ice water, and the ice water is clear; detect it with potassium iodide test paper, it turns blue, and the diazotization reaction is completed, and a diazonium salt solution is obtained. In a 2000ml beaker, set it up and stir, add 400.0g of glass beads with a particle size of 1mm and 200.0g of sea sand with a particle size of 1mm into the beaker, add 500.0g of water, add 1.0g of flat plus emulsifier and 2.0 gMF dispersant, then add 47.7g (content 99.0%, 0.2mol) of coupling component N-cyanoethyl-N-benzylaniline, start stirring, control pH=1-2, start stirring, and keep grinding for 1.5 hours , so that the coup...

Embodiment 2

[0031] Change the amount of coupling component to 45.3g (content 99.0%, 0.19mol), the grinding medium to 906.0g of glass beads with a particle size of 2.0mm, the amount of water added to 679.5g, and the emulsifier to 0.453g of OP -10, the dispersant was changed to 2.25g dispersant Reax85A, and other operating methods were the same as in Example 1, and 71.9g of Disperse Orange 288 filter cake was obtained, with a purity of 96.4% (HPLC), and a molar yield of 94.7% (in terms of coupling components) ).

Embodiment 3

[0037] Change the amount of coupling components to 50.1g (content 99.0%, 0.21mol), the grinding medium to 906.0g zirconia beads with a particle size of 0.5mm, the amount of water added to 679.5g, and the emulsifier to 2.5g NP-30, the dispersant was changed to 0.453g dispersant Reax85A, other operating methods were the same as in Example 1, and 78.5g of Disperse Orange 288 filter cake was obtained, with a purity of 95.7% (HPLC), and a molar yield of 92.8% (based on the coupling composition score).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com