Strain capable of massively yielding glucose-6-acetic ester and method for synthesizing glucose-6-acetic ester

A technology of glucose and acetate, applied in the field of biochemical engineering, can solve the problems of poor passage stability, low yield, unsuitable for industrial production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

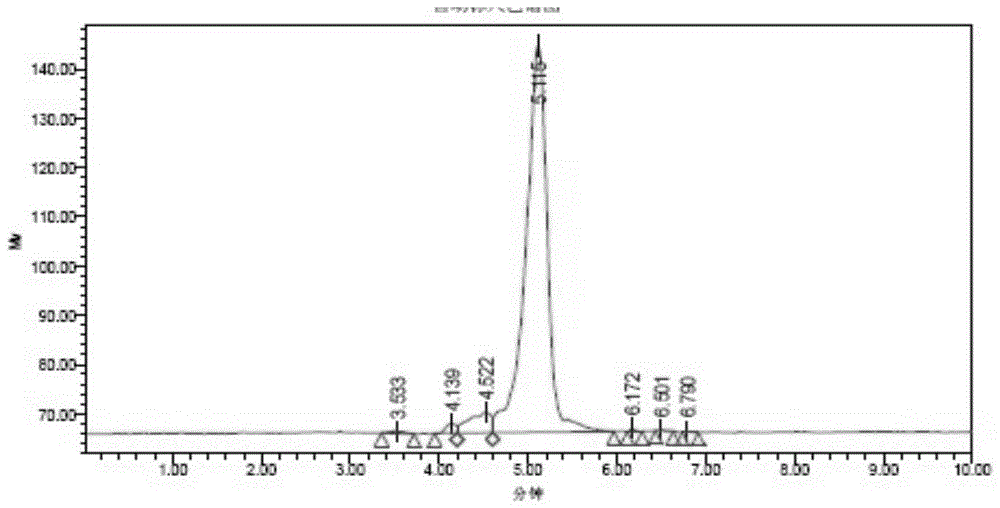

[0056] The steps of the fermentation separation method for producing glucose-6-acetate are as follows:

[0057] (1) Bacterial slant culture

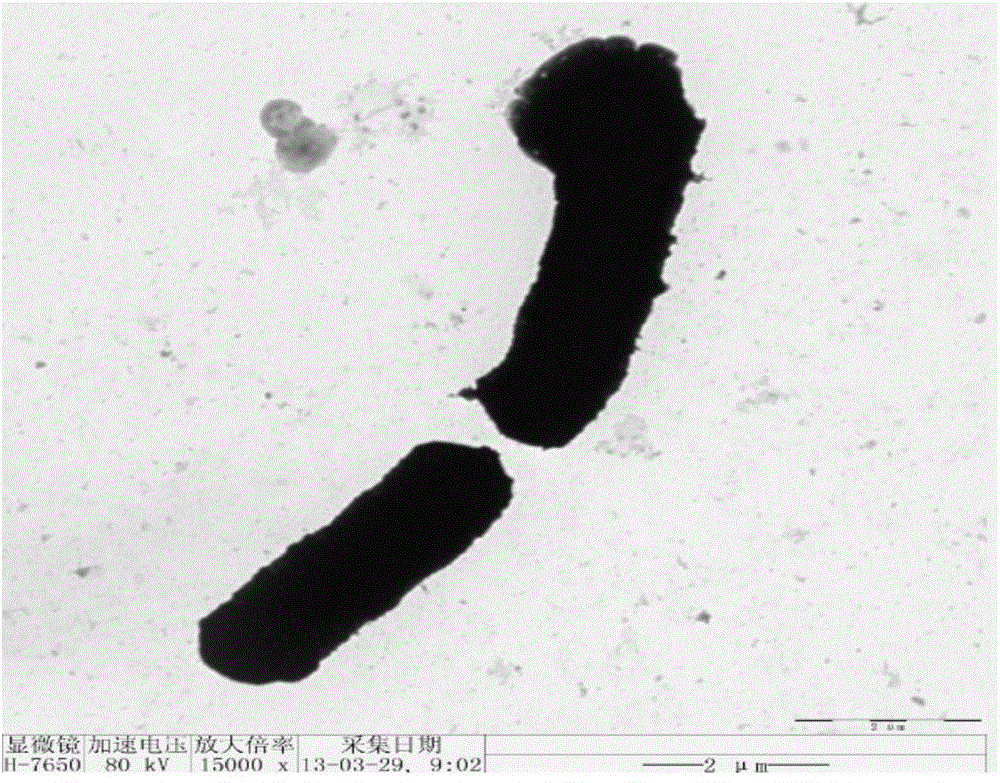

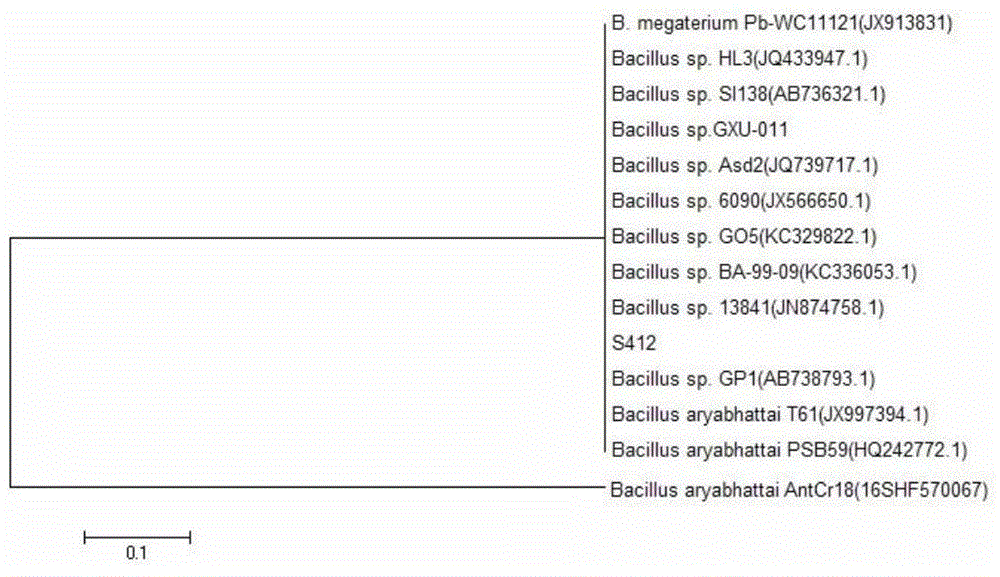

[0058] Bacillus sp. (Bacillus sp.) strain GXU-011 bacterial classification is inoculated into the slant culture medium in the test tube to make the slant bacterial classification;

[0059] Wherein the bacterial strain slant culture medium is made up of following components by weight:

[0060] Sucrose 40g, yeast powder 2g, KH 2 PO 4 0.5g, K 2 HPO 4 0.5g, MgSO 4 0.5g, agar powder 15g and water 1000 parts;

[0061] The technological conditions for preparing slant strains are pH 6.5, temperature 28° C., and incubation time 24 hours.

[0062] (2) Inoculation fermentation

[0063] Expand and cultivate the slant strains into seed liquid;

[0064] The seed liquid is inserted in the fermenter by 5% inoculum size and fermented;

[0065] Wherein the seed liquid and the fermented liquid consist of the following components in parts by weigh...

Embodiment 2

[0076] The steps of the fermentation separation method for producing glucose-6-acetate are as follows:

[0077] (1) Bacterial slant culture

[0078] Bacillus sp. (Bacillus sp.) strain GXU-011 bacterial classification is inoculated into the slant culture medium in the test tube to make the slant bacterial classification;

[0079] Wherein the bacterial strain slant culture medium is made up of following components by weight:

[0080] 50g of sucrose, 6g of yeast powder, KH 2 PO 4 2g, K 2 HPO 4 2g, MgSO 4 2g, agar powder 20g and water 1000 parts;

[0081] The technological conditions for preparing the slant strain are pH value 7.0, temperature 30° C., and incubation time 30 hours.

[0082] (2) Inoculation fermentation

[0083] Expand and cultivate the slant strains into seed liquid;

[0084] The seed liquid is inserted in the fermenter by 8% inoculum size and fermented;

[0085] Wherein the seed liquid and the fermented liquid consist of the following components in parts...

Embodiment 3

[0093] The steps of the fermentation separation method for producing glucose-6-acetate are as follows:

[0094] (1) Bacterial slant culture

[0095] Bacillus sp. (Bacillus sp.) strain GXU-011 bacterial classification is inoculated into the slant culture medium in the test tube to make the slant bacterial classification;

[0096] Wherein the bacterial strain slant culture medium is made up of following components by weight:

[0097] Sucrose 60g, yeast powder 8g, KH 2 PO 4 1.5g, K 2 HPO 4 1.5g, MgSO 4 1.5g, 25g of agar powder and 1000 parts of water;

[0098] The technological conditions for preparing slant strains are pH value 7.5, temperature 32° C., and incubation time 36 hours.

[0099] (2) Inoculation fermentation

[0100] Expand and cultivate the slant strains into seed liquid;

[0101] The seed liquid is inserted in the fermenter by 10% inoculum size and fermented;

[0102] Wherein the seed liquid and the fermented liquid consist of the following components in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com