Combined-cycle combined heat and power system

A technology of combined heat and power supply and combined cycle, which is applied in the fields of combined combustion mitigation, energy industry, steam engine installations, etc., can solve the problems of reduced efficiency of the whole machine, damage to the medium-pressure flow structure, waste of temperature difference, etc., and achieves improved power generation efficiency and high The effect of improving the quality of energy waste and reducing the waste of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] In a gas-fired thermal power plant project, two sets of F-class one-to-one units are required. The heat supply requirement is: 1.8MPa, 285°C. The rated heat supply of a single unit is: 130t / h, and the maximum is 210t / h. When the other set fails, the maximum heating requirement of this unit is 250t / h. in:

[0077] High pressure steam parameter is 13MPa, 560℃;

[0078] Reheat (ie medium pressure) steam parameter is 3.0MPa, 550℃;

[0079] Low-pressure steam parameter is 0.3MPa, 240°C;

[0080] High exhaust steam parameters are 2.5MPa, 335°C.

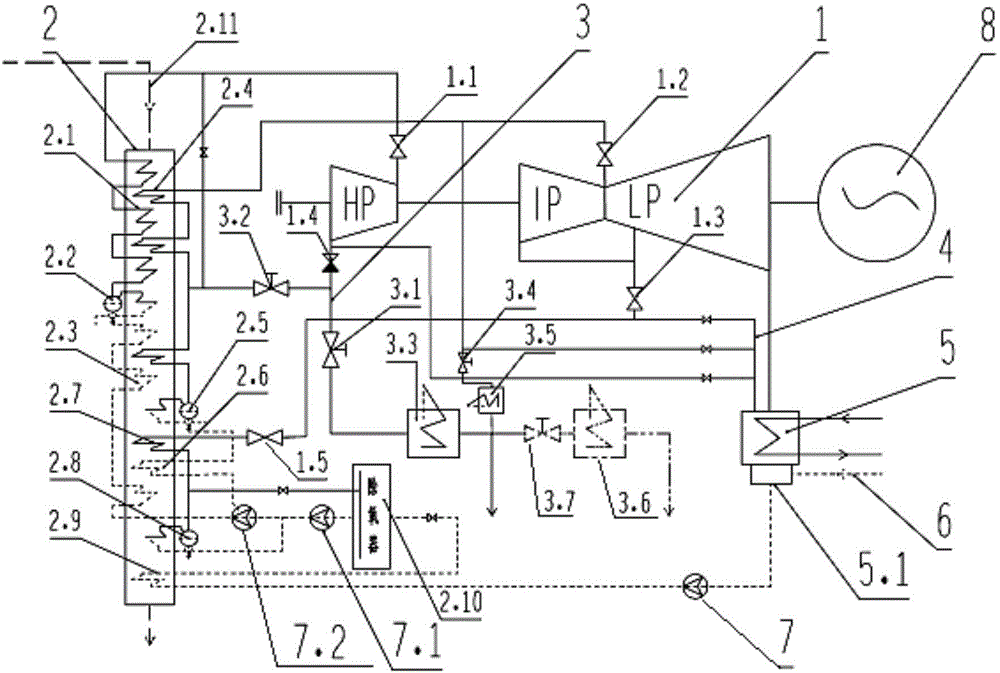

[0081] then as figure 1 As shown, two sets of combined heat and power cogeneration systems of the combined cycle of the present invention are used.

[0082] Steam turbine 1 is a three-pressure, reheating combined cycle steam turbine, including a high-pressure cylinder HP, an intermediate-pressure cylinder IP and a low-pressure cylinder LP. 1. The structure of the combined cylinder of the medium pressure cylinder IP and the low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com