Optical fiber micro-displacement air pressure detecting device

An air pressure measurement device and micro-displacement technology, which is applied to measurement devices, optical devices, fluid pressure measurement using optical methods, etc., can solve the problems of increasing the cost and achieve the effects of convenient processing, simple operation, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

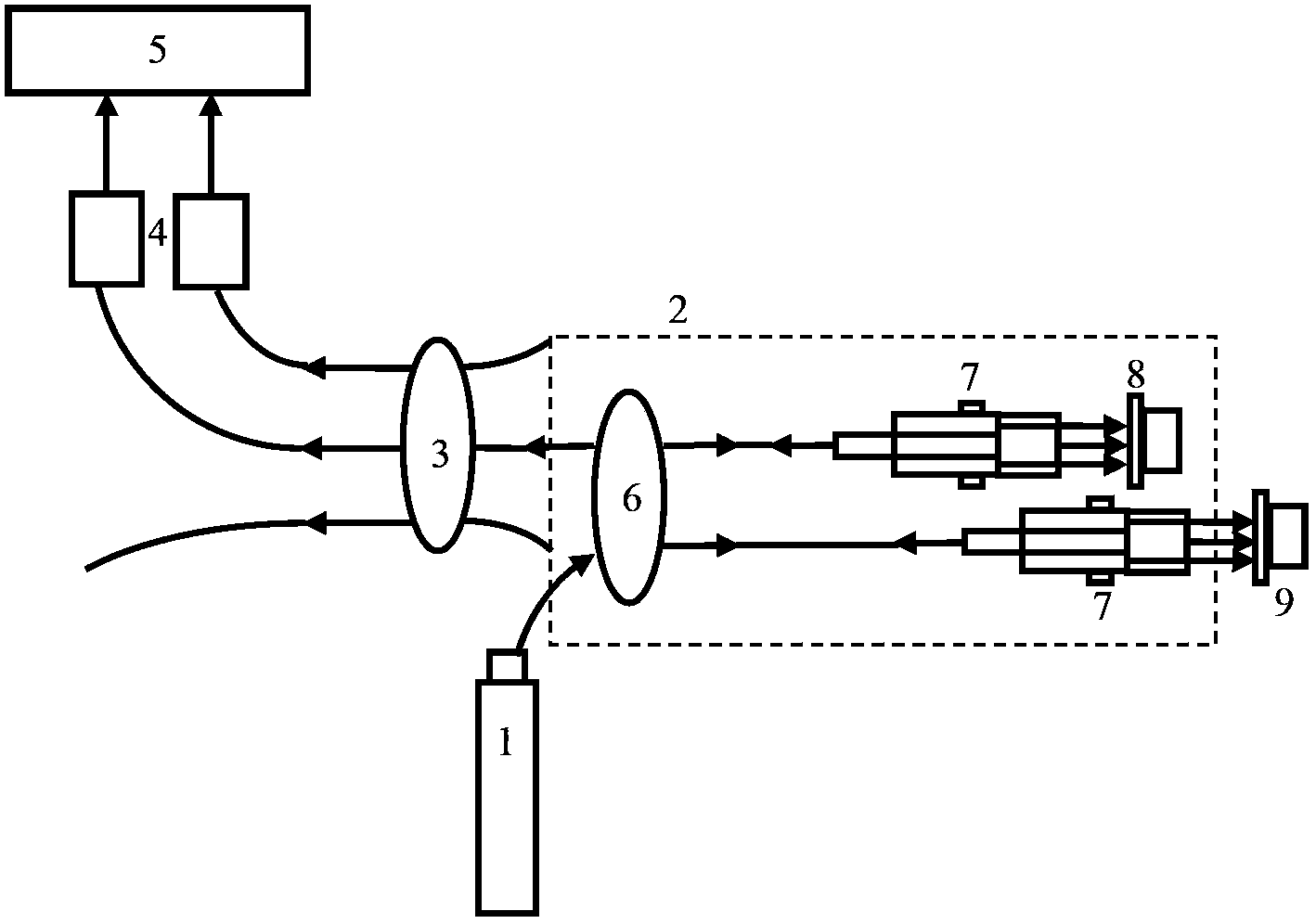

[0036] according to figure 1 The structure diagram of the preliminary experimental verification device construction, such as Figure 6 shown. The light emitted by the 1550nm (±3nm, power 2-5mw) narrow-band light source 1 passes through the 2×2 coupling device 6 and then enters the optical fiber micro-displacement sensor. The output end face of the straightener 7 is emitted, and part of it is reflected back into the original optical fiber through a reference angle cone diaphragm 8 to become the reference light, and the other part is reflected back into the original fiber through the angle cone diaphragm 9 to be measured, which is the light to be measured. Light; the two light beams have an optical path difference due to the difference in arm length, and interference occurs in the fiber coupler 6. After the interference signal passes through a 3×3 coupler 3, two beams of light waves with two fixed phase differences are selected to pass through the photoelectric Converter 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com