Device and method for measuring transient moisture vapor transmission of variable density fiber plug

A technology for measuring devices and fiber plugs, which is applied in the direction of measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve the problems of complex test devices, few transient test methods, and inability to measure fiber plugs, etc., to achieve repeatability and Excellent reproducibility, shortened test time, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

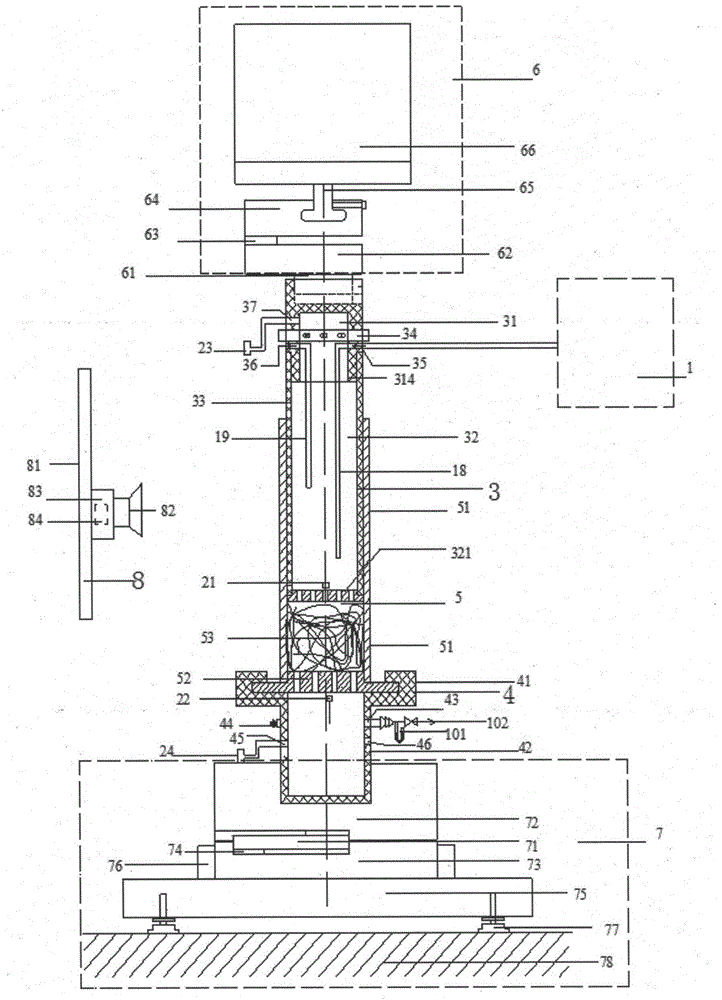

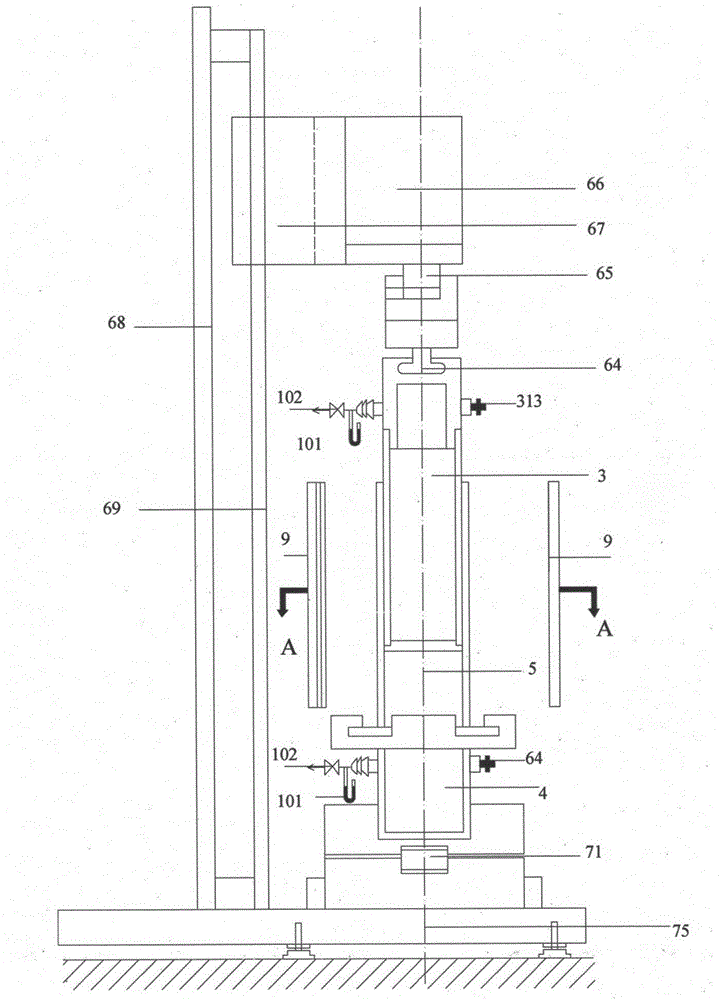

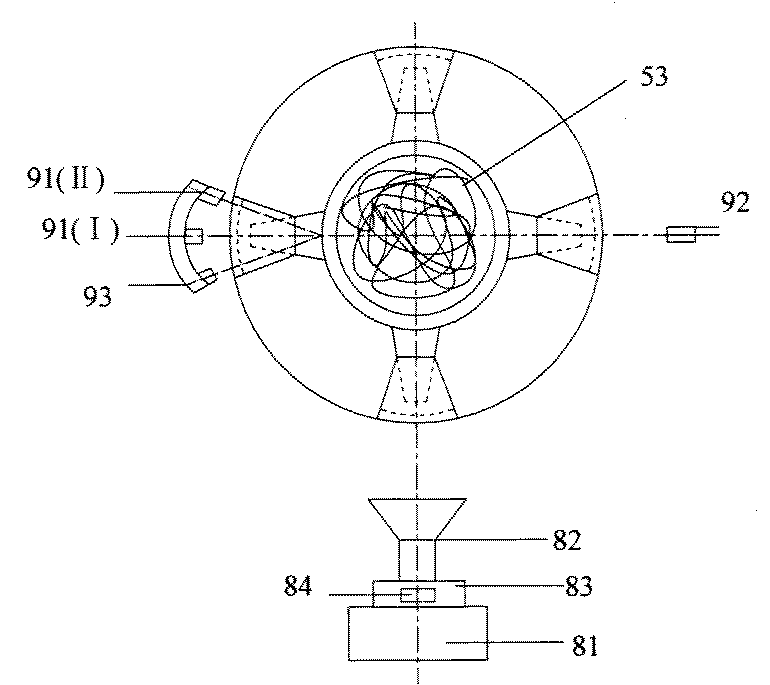

[0095] The wool fiber plug was selected for testing, the diameter of the wool was 21 μm, and the curl was 4.68 pieces / cm. Before the test, the wool fiber sample is preset for 24 hours under constant temperature and humidity conditions with a temperature of 20±0.2°C and a relative humidity of 65±5%. Put 0.3g of randomly arranged fiber plugs into the fiber plug tube 5, then fit the fiber plug tube 5 and the lower measurement cavity 4 together, place them on the groove of the force positioning device 7, and then push the tube into the measurement cavity The transom hole 34 on 3 is opened, and is suspended on the main force applying device 6, and the starting motor drives the pusher measuring chamber 3 to rise to the highest position, so that the pusher measuring chamber 3 and the fiber plug 5 are separated, and the pusher measuring chamber and the fiber plug 5 are separated. Put an airtight plastic film between the fiber plug tubes to prevent water vapor from entering the fiber p...

Embodiment 2

[0097] Select several representative fabrics of different weights and types, as shown in Table 1. Before the test, the fabric sample is preset for 24h under constant temperature and humidity conditions with a temperature of 20±0.2°C and a relative humidity of 65±5%. Cut the fabric into a circle with a diameter of 3 cm, put it on the bottom plate of the fiber plug tube 5, then clamp the fiber plug tube 5 and the lower measurement chamber 4 together, place it on the groove of the force positioning device 7, and then Open the transom hole 34 on the push tube measurement cavity 3 to make it in the open state, and hang it on the main force applying device 6, start the motor to drive the push tube measurement cavity 3 to rise to the highest position, so that the push tube measurement cavity 3 and the fiber plug The cylinder 5 is separated, and an airtight plastic film is placed between the push cylinder measurement chamber and the fiber plug cylinder to prevent water vapor from ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com