[0002] In the existing technology, the engineering materials are all determined according to the specifications, sizes and packaging of shopping malls, which is a general supply mode, and the content of engineering materials is often determined by professional engineering personnel according to the

working environment and space and personal

professional skills. , the amount of supply received for smooth construction will be far greater than the actual amount of construction, and the problems of material

cutting loss, surplus material and material control, and

work space conflicts are often ignored, and even affect the quality of construction, resulting in major losses, often missing analysis as follows:

[0003] (1) The supply of engineering materials is greater than the actual amount used. The use of materials during construction must be carried out according to the actual environment and space. The commercially available materials are general-purpose specifications and sizes that do not match the job site.

Cutting operations must be carried out. We can only consider the actual demand, and there will be a large amount of surplus material. The management and use of surplus material is a big problem. The surplus material is not recorded and is easily polluted by the construction environment, such as water,

moisture, oil, dust, etc., and it will last for a long time. In the case of oxidation, general engineers will not take the initiative to use it, and often form a large amount of waste at the end of the project.

[0004] (2) The selection of engineering materials is often determined by the engineering personnel. The engineering personnel must carry out the operation on the spot. Before the operation according to the design drawing, they must spend a lot of time measuring and knowing the content of the combined materials, and carry out necessary

cutting, measuring, and comparison combinations. , Construction procedures, the use of residual materials is often not checked when cutting operations, and the content of residual materials is not recorded after cutting. The residual materials are sent back to the warehouse. Management of residual materials and the use of residual materials is a difficult problem in engineering operations, which is time-consuming and laborious. be able to effectively eliminate losses

[0005] (3) The use content of engineering materials will not be marked, and the construction personnel will use them as needed, which may easily lead to misuse or uneven distribution. There are control blind spots

[0006] (4) Existing engineering operations are guided by the design drawing, but the design drawing can only see the part of the work, and cannot view other construction content. It is inevitable that there will be operation conflicts, resulting in loss of engineering operation modification. Problems are often discovered after construction, and the design drawings cannot fully state the sequence of operations and the content of combined materials. The construction personnel must explore by themselves, spending a lot of time, prone to operational errors, and difficult to control the progress of engineering operations

[0007] (5) It is difficult to check the materials used in existing projects. Because the construction materials are not marked, it is impossible to show whether they meet the operation specifications in real time. Only by checking the design drawings and material specifications can it be clear. The check work is time-consuming and laborious, and engineering personnel often do not know everything Check, construct as long as materials are available, prone to errors

[0008] (6) In the linking part of the project construction, it is often necessary to mark and mark the connecting marks for future operations. However, the existing marking operations are carried out by the engineers themselves, and there is no unified standard for the operation. The above-mentioned marks The content is only clear to some personnel, and it is often carried out by different personnel after a long time, or when the content of the

label cannot be seen or falls off due to environmental factors, it must be re-checked and confirmed, which will increase a lot of time

[0009] (7) For the existing combined products, although the materials have been prepared, there is no guidance information on the materials and the operation method. You must check the combination manual. Everyone may not be clear about the content of the manual, the

order of operations and the adjustment of the direction of the materials used. More often than not, problems arise

The basic essentials of

assembly technology, when the instructions cannot be clearly explained, the error is only discovered after assembly, which is time-consuming and labor-intensive due to many difficulties, and often requires multiple combinations to understand the essentials

[0010] In summary, there is no automatic guidance function and special material mode for the materials used in the above-mentioned engineering construction. In the engineering operation, there are not only difficulties in management and construction, waste and loss, but also blind spots in the management and control of surplus materials, and problems in the management of incoming and outgoing warehouses. The risk of lack of materials hindering construction due to uneven distribution of materials is a common problem in traditional labor-intensive industries, such as power distribution production,

mechanical equipment manufacturing, equipment installation tools, electrical power distribution engineering,

piping engineering,

fire protection engineering, Human labor markets such as air-conditioning engineering,

water supply and drainage engineering, communication engineering,

construction engineering, appliance assembly engineering, interior decoration engineering, furniture and kitchenware assembly, and personal DIY assembly products are often seen

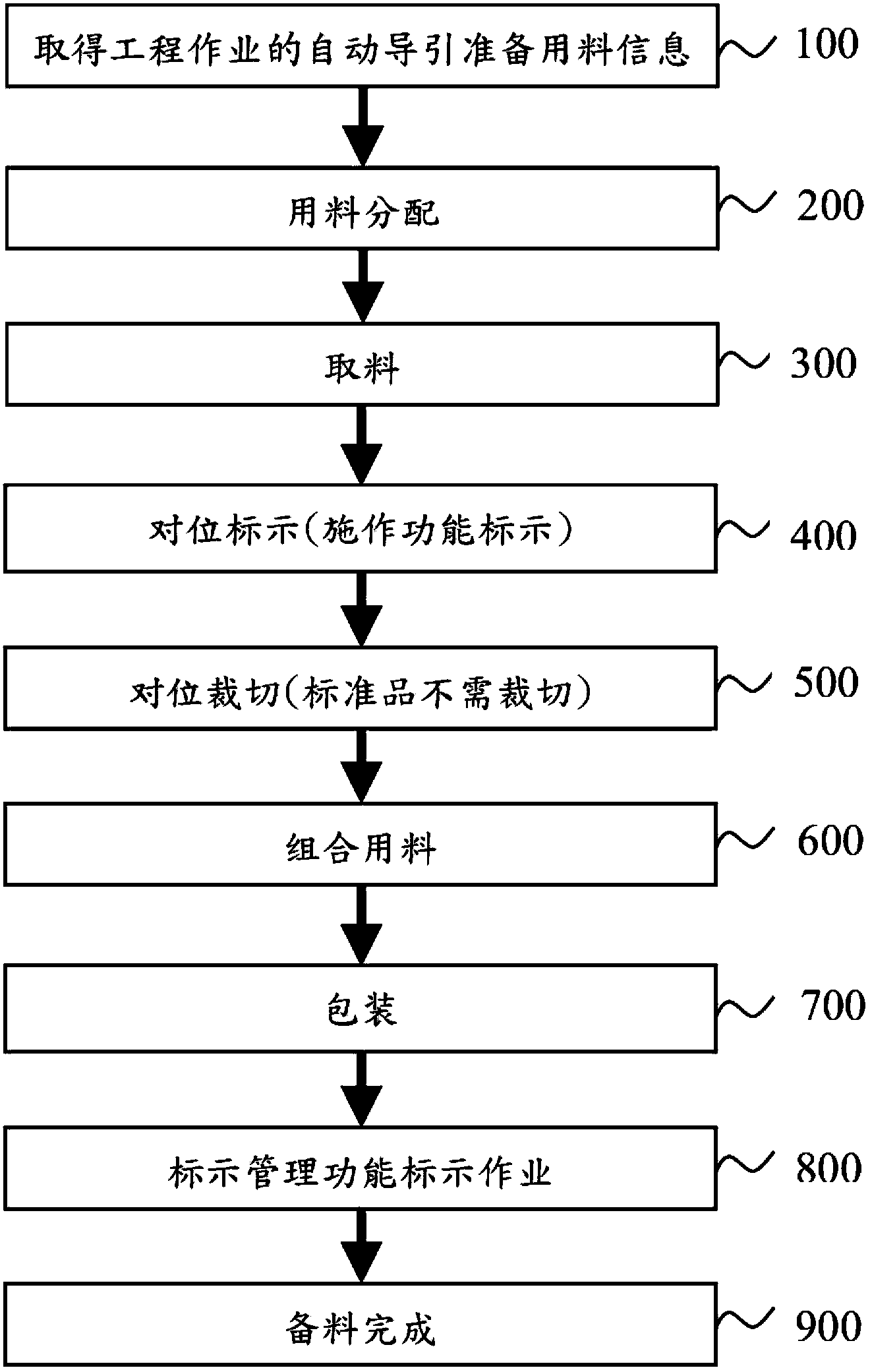

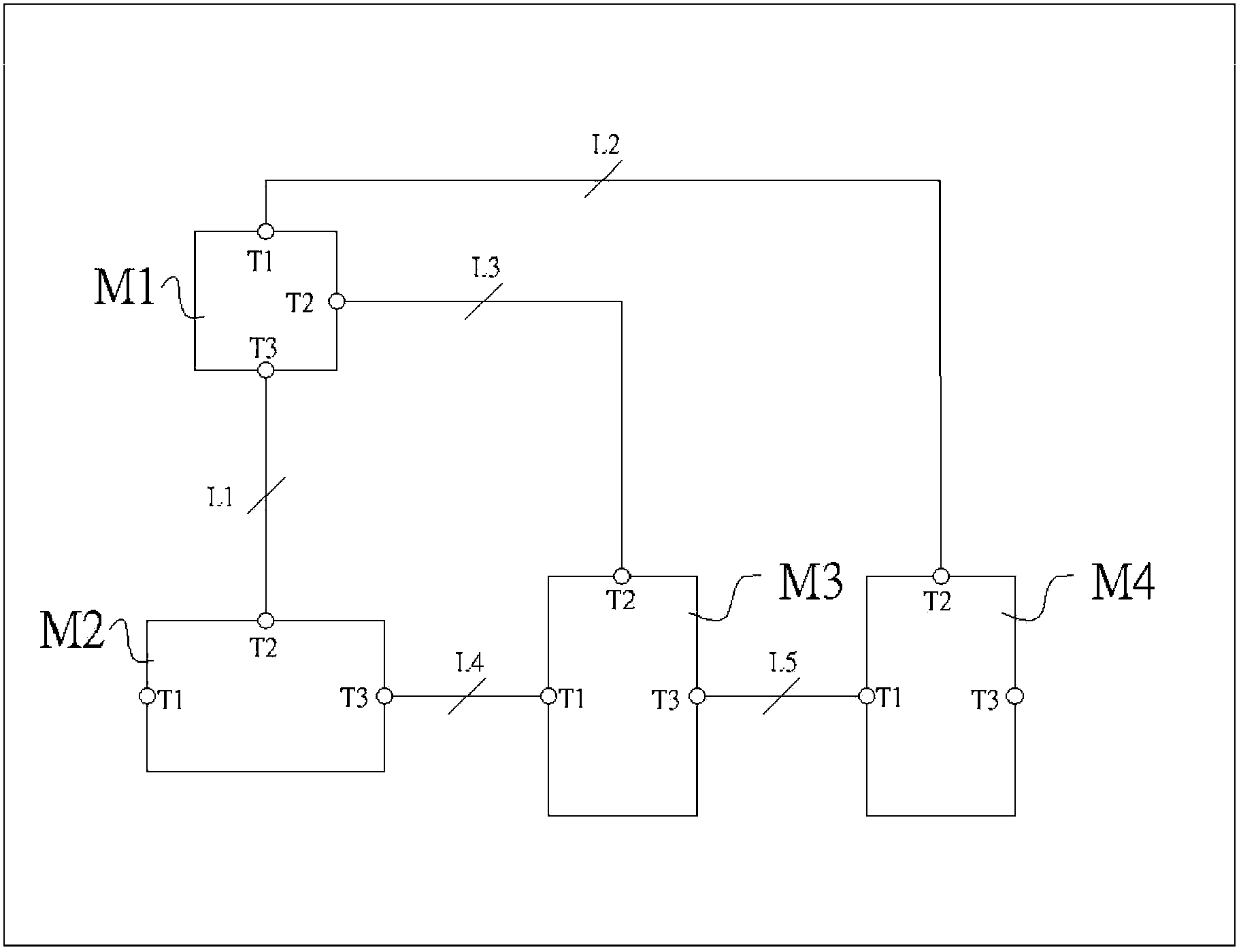

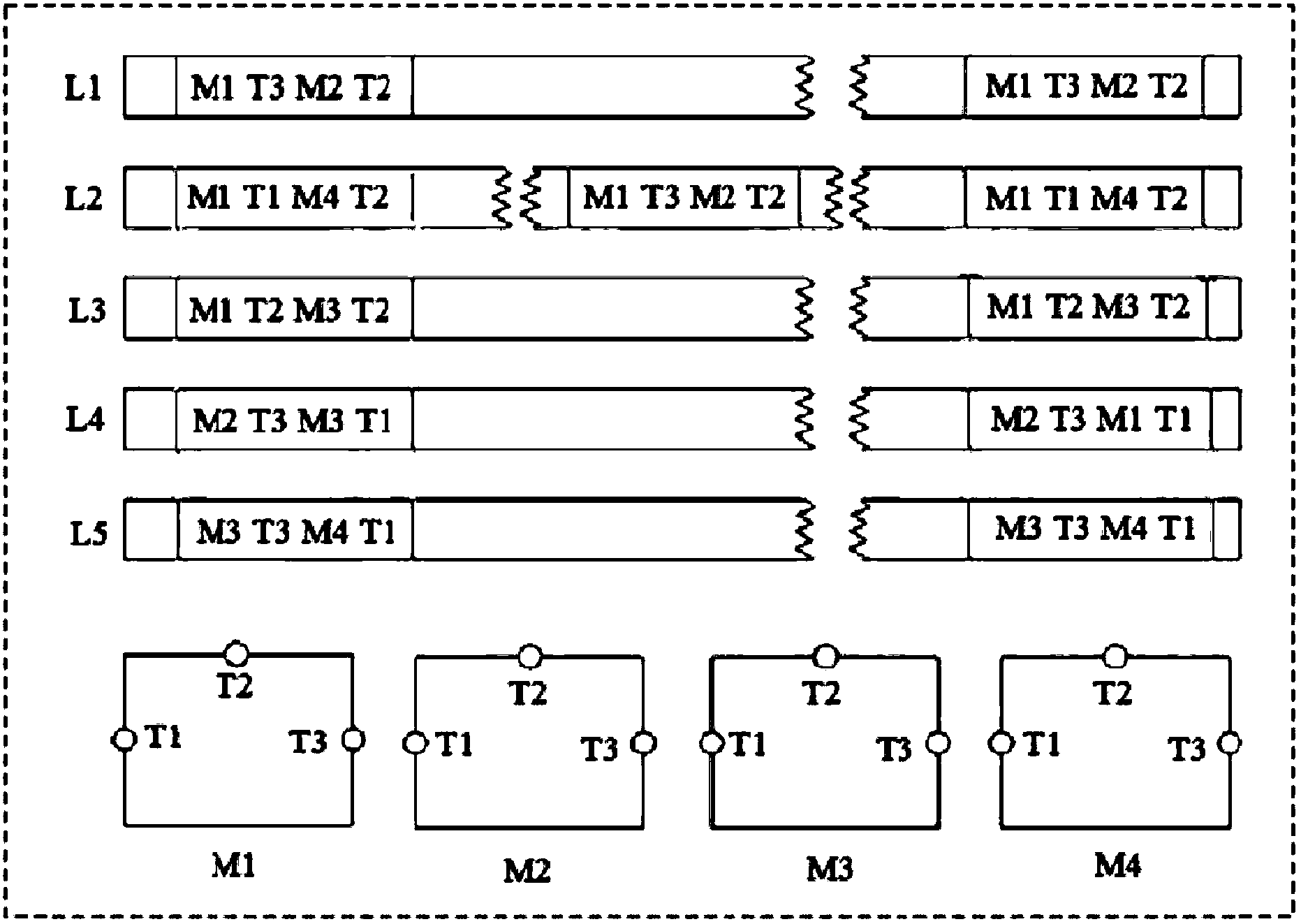

Login to View More

Login to View More  Login to View More

Login to View More