Low Power Metal Halide DC Lamp

A metal halide, low-power technology, which is applied to the components of gas discharge lamps, etc., can solve the problems of shortening the service life of DC lamps, unstable light, and unstable use, and achieve stable light output, stable arc, The effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

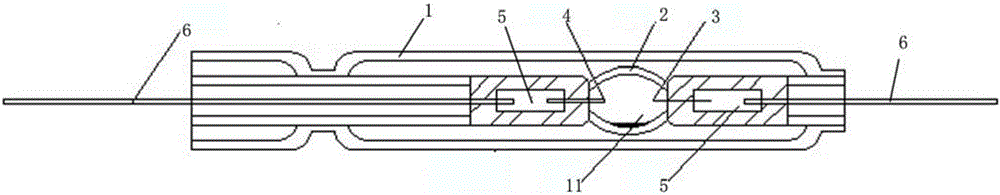

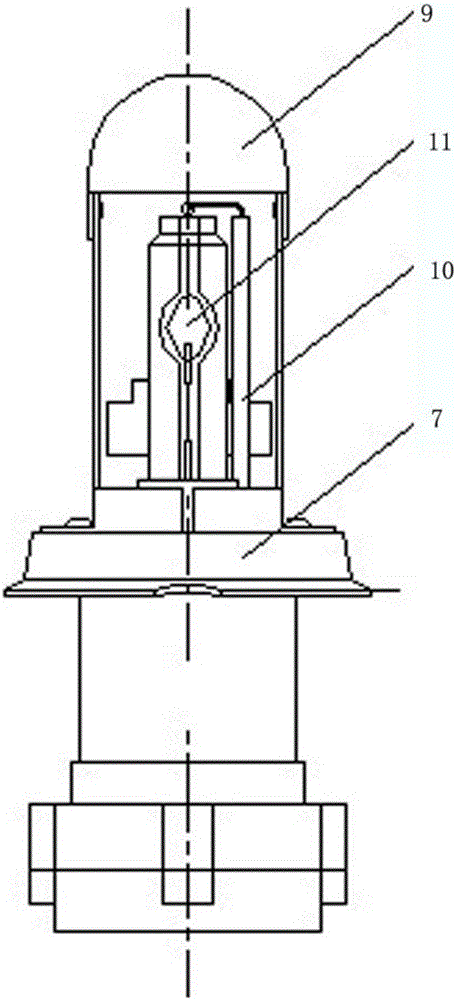

Embodiment 1

[0025] A light-emitting arc tube made of quartz glass with an outer diameter of 6.0mm, a length of 7.2mm, and a wall thickness of 1.0mm, and a cathode with a diameter of 0.1mm and an anode with a diameter of 0.2mm enclosed therein form a discharge chamber 11 in the light-emitting arc tube. The discharge distance between the anodes is 4.0mm; before sealing the discharge chamber, add 0.7mg of mercury, ScI 3 :NaI:ThI 4 =22:75: After 3 grains of metal halides with a weight of 0.2 mg and zinc iodide of 0.05 mg, xenon gas with a pressure of 6 atmospheres is filled through high vacuum exhaust, and then the discharge chamber is sealed to make the discharge chamber in Vacuum-sealed state; the two electrodes are connected to the light-emitting arc tube through the non-matching airtight sealing characteristics of the molybdenum sheet, and the electrical connection to the molybdenum sheet is completed by the lead wire of the molybdenum rod; the width of the molybdenum sheet is 1.5mm, and ...

Embodiment 2

[0027] A light-emitting arc tube made of quartz glass with an outer diameter of 7.0mm, a length of 8.5mm, and a wall thickness of 1.2mm, and a cathode with a diameter of 0.25mm and an anode with a diameter of 0.4mm enclosed therein form a discharge chamber 11 in the light-emitting arc tube. The discharge distance between the anodes is 4.8mm; before sealing the discharge chamber, add 0.9mg of mercury, 0.2mg of TLI metal halide, and 0.05mg of zinc iodide into the discharge chamber, and then discharge through high vacuum The gas is filled with xenon gas at 4.5 atmospheres, and then the discharge chamber is sealed to make the discharge chamber in a vacuum-sealed state; the two electrodes are connected to the light-emitting arc tube through the non-matching airtight sealing characteristics of the molybdenum sheet, and are lead by the molybdenum rod Complete the electrical connection with the molybdenum sheet; the width of the molybdenum sheet is 2.0mm, and the thickness is 0.024mm; ...

Embodiment 3

[0029]A light-emitting arc tube made of quartz glass with an outer diameter of 5.5 mm and a wall thickness of 1 mm, and a cathode with a diameter of 0.15 mm and an anode with a diameter of 0.25 mm enclosed in it form a discharge chamber 11 in the light-emitting arc tube, and the discharge between the cathode and the anode The distance is 3.5mm; before sealing the discharge chamber, add 0.6mg of mercury, 0.25mg of InI metal halide and 0.1mg of zinc iodide into the discharge chamber, and then fill 6.5 cells with high vacuum exhaust. Atmospheric xenon gas, and then seal the discharge chamber so that the discharge chamber is in a vacuum-sealed state; the two electrodes are connected to the light-emitting arc tube through the non-matching airtight sealing characteristics of the molybdenum sheet, and the molybdenum rod lead wire completes the connection with the molybdenum sheet Electrical connection; the width of the molybdenum sheet is 1.0mm, and the thickness is 0.023mm; then put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com