Adjustable high-stable F-P integrated endoscope device

A F-P, high stability technology, applied in the structure/shape of the optical resonator, can solve the problems of optical path closed spectral line intensity output, adverse effects of fineness, inability to conveniently place the sample cell in the cavity, and inability to provide mechanical structures, etc. Achieve the effects of reducing spectral line frequency drift, simple structure, and high signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

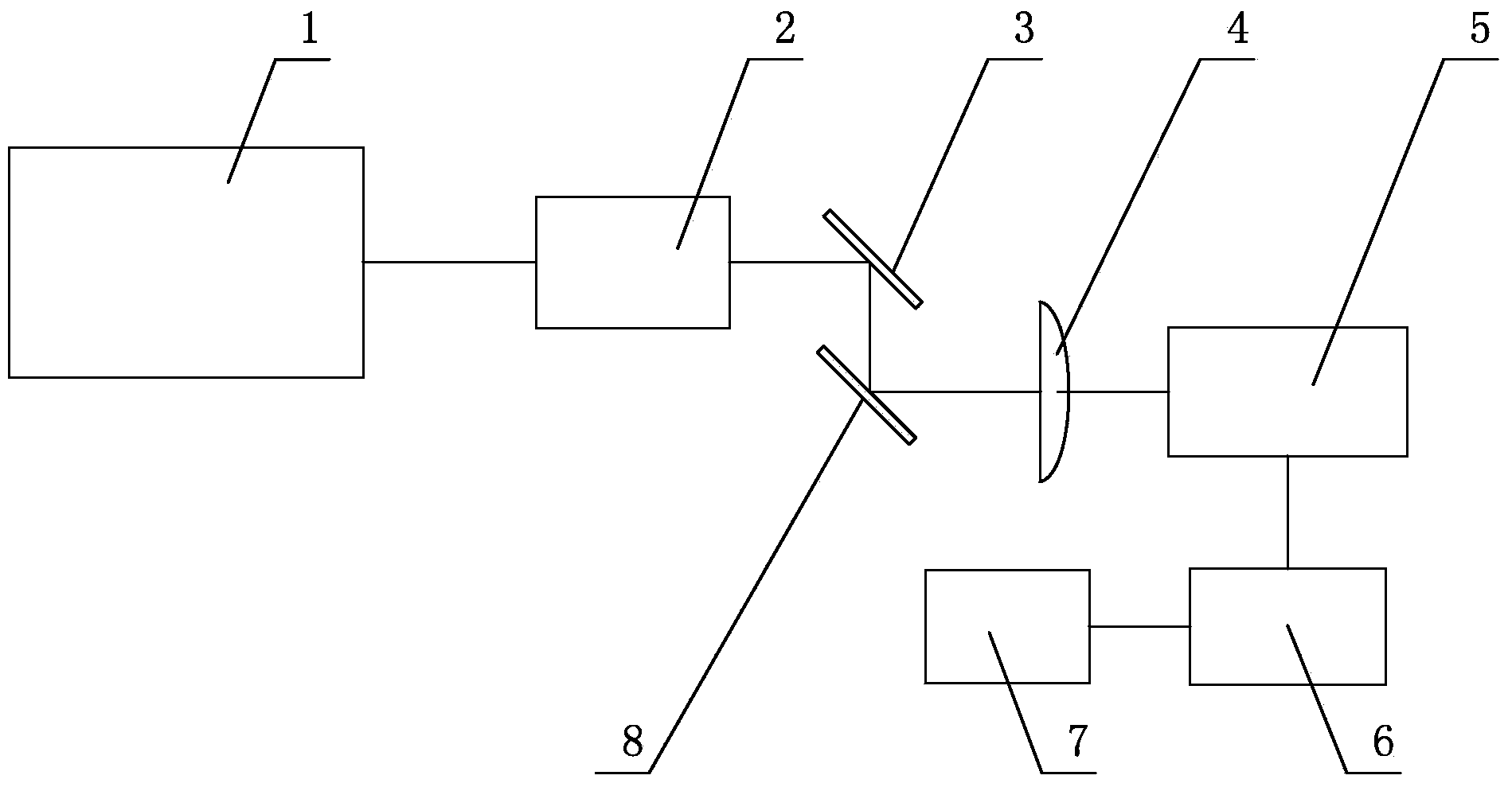

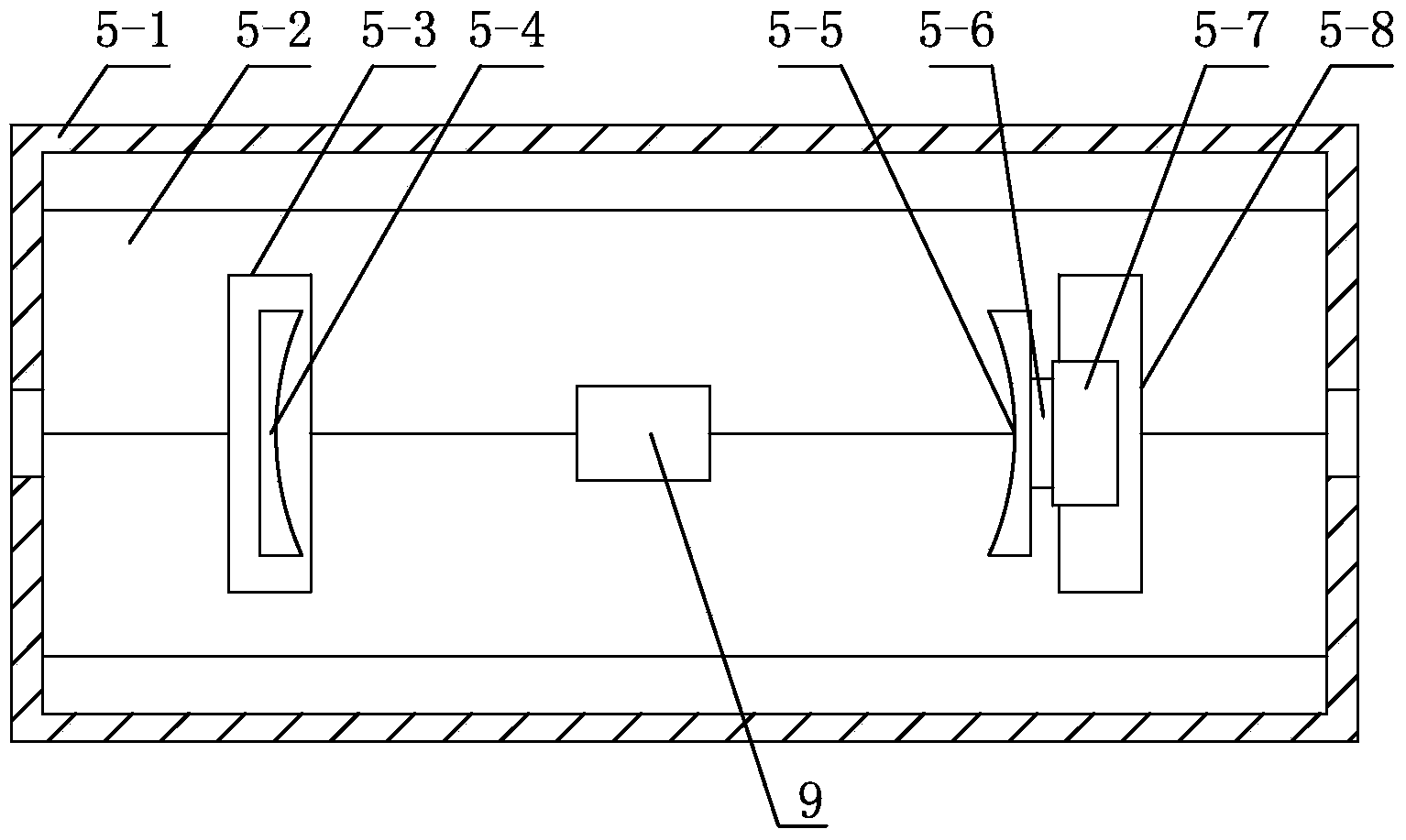

[0024] Depend on figure 1 It can be seen that the adjustable F-P integral cavity device of this embodiment is connected by a light source 1, an optical isolator 2, a first plane mirror 3, a matching lens 4, an F-P integral cavity mirror group 5, a high-voltage amplifier 6, a signal source 7, and a second plane mirror 8 constitute.

[0025] The laser of this embodiment is used as a light source 1, and emits laser light with a wavelength of 633nm. An optical isolator 2 is installed at a position 10mm away from the laser on the outgoing optical path of the laser light. The center wavelength of the optical isolator 2 is 650nm, and the applicable wavelength range is 630 to 700nm. , the transmittance is 75%, and the isolation is 30dB. A reflective plane mirror group is installed at a position 220 mm away from the optical isolator on the exit light path of the optical isolator 2 to adjust the optical center of the laser light path. The reflective plane mirror group includes the first...

Embodiment 2

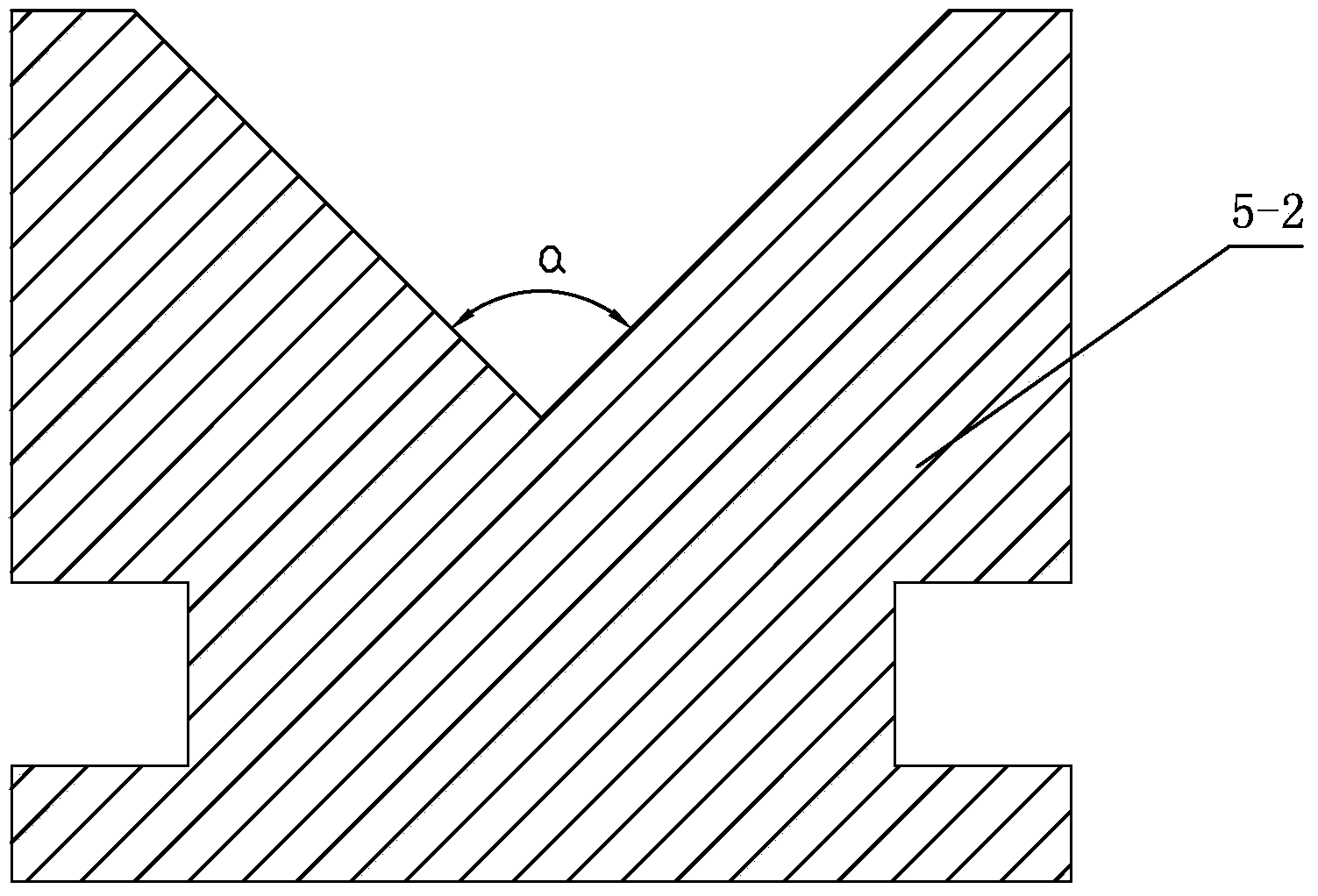

[0030] The laser of this embodiment is used as a light source 1 to emit laser light, and an optical isolator 2 is installed at a position 10 mm away from the laser on the outgoing light path of the laser light, and a reflective flat mirror is installed at a position 220 mm away from the optical isolator on the outgoing light path of the optical isolator 2 group, the reflective plane mirror group includes a first plane mirror 3 and a second plane mirror 8, the first plane mirror 3 is installed on the exit light path of the optical isolator 2 and forms an included angle of 45° with the exit light path, and the second plane mirror 8 is installed on Directly below the first plane mirror 3, parallel to the first plane mirror 3, the center distance between the first plane mirror 3 and the second plane mirror 8 is 20mm, the light is reflected from the first plane mirror 3 to the second plane mirror 8, and then from the second plane mirror 8 is reflected, on the reflected optical path ...

Embodiment 3

[0035] The laser of this embodiment is used as a light source 1 to emit laser light, and an optical isolator 2 is installed at a position 10 mm away from the laser on the outgoing light path of the laser light, and a reflective flat mirror is installed at a position 220 mm away from the optical isolator on the outgoing light path of the optical isolator 2 group, the reflective plane mirror group includes a first plane mirror 3 and a second plane mirror 8, the first plane mirror 3 is installed on the exit light path of the optical isolator 2 and forms an included angle of 45° with the exit light path, and the second plane mirror 8 is installed on Directly below the first plane mirror 3, parallel to the first plane mirror 3, the center distance between the first plane mirror 3 and the second plane mirror 8 is 80mm, and the light is reflected from the first plane mirror 3 to the second plane mirror 8, and then from the second plane mirror 8 is reflected, and on the reflected light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Isolation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com