Method for strengthening filter capacity of osmotic membrane through dielectrophoresis technology

A technology of dielectrophoresis and filtration ability, applied in the field of separation, can solve problems such as unsuitable industrial conditions, hindering widespread use, pH value changes, etc., to achieve the effect of increasing membrane permeation, increasing service life, reducing energy and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of method adopting dielectrophoresis technique to strengthen the filtration ability of osmotic membrane, the steps are:

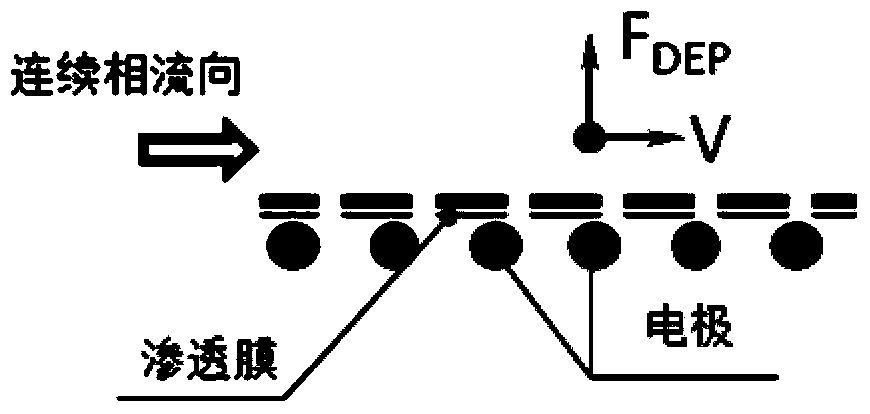

[0025] (1) Microfiltration technology is used to separate the suspension of 5 grams per liter of clay in water, and the interdigitated electrode structure composed of cylindrical electrodes is installed under the microfiltration osmotic membrane. Because the dielectric polarization ability of clay is much smaller than that of water, it exhibits negative dielectrophoretic properties, so that small clay particles (most particles with a diameter of about 100 nanometers) are pushed away from the microfiltration permeable membrane to reduce membrane fouling, such as figure 1 shown.

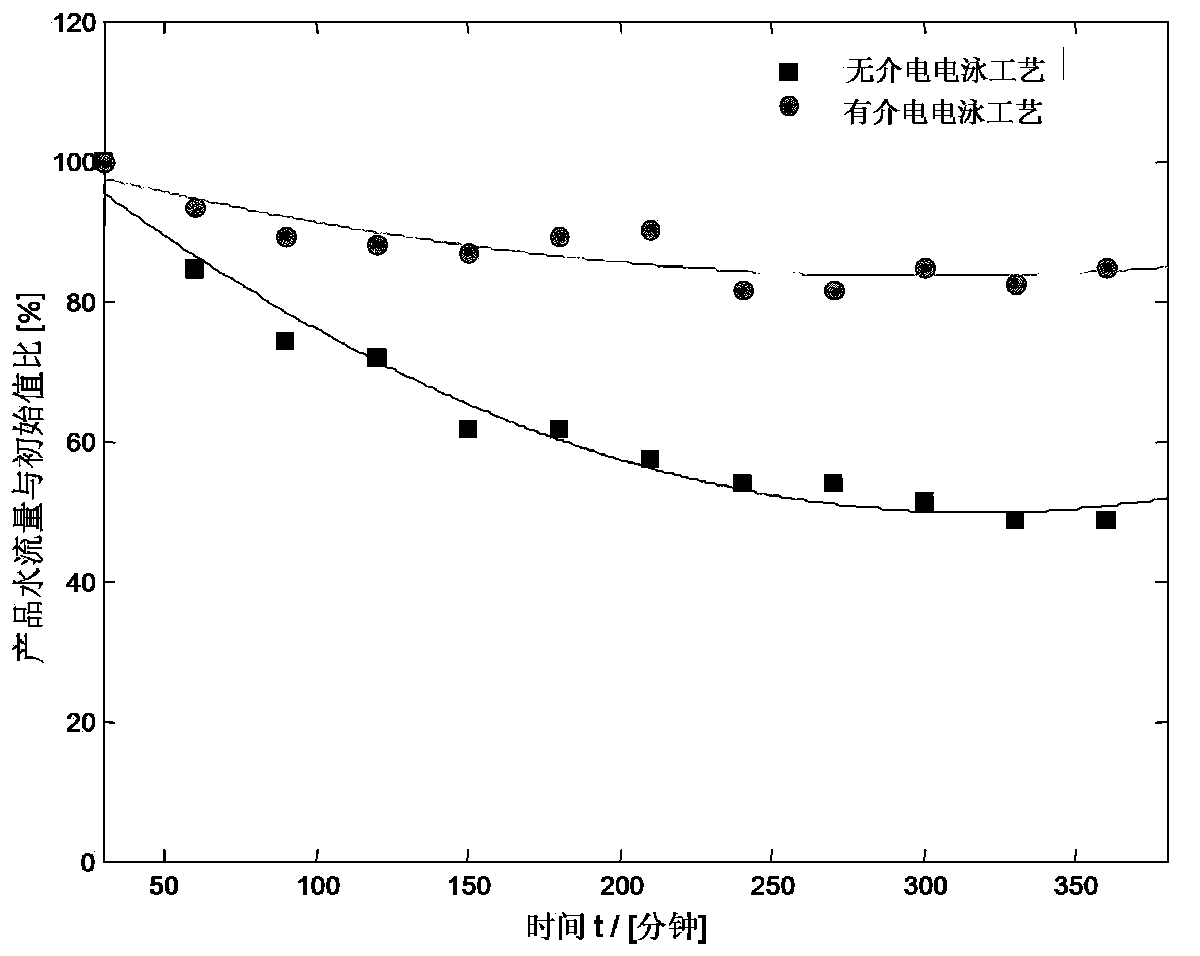

[0026] (2) When the dielectrophoretic force is continuously applied, that is, the voltage is 300V, the frequency is 200KHZ, and the continuous application of uninterrupted power supply, within six hours, the membrane permeation is stable at more than 82% of the acciden...

Embodiment 2

[0029] A kind of method adopting dielectrophoresis technique to strengthen the filtration ability of osmotic membrane, the steps are:

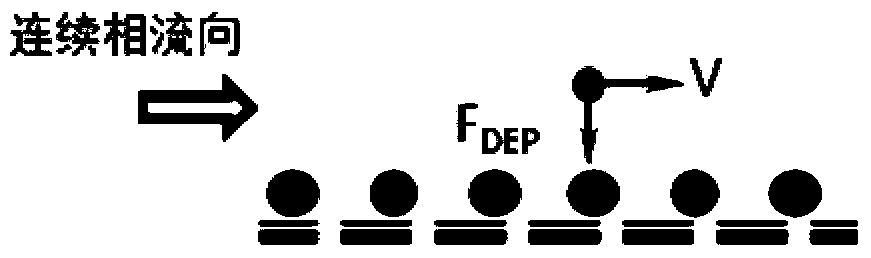

[0030] ⑴ Microfiltration technology is used to separate the suspension of 5 grams per liter of metal particles in water, and the interdigitated electrode structure composed of cylindrical electrodes is installed in the microfiltration osmotic membrane. Since the dielectric polarization ability of metal particles is much greater than that of water, it exhibits positive dielectrophoretic properties, so that small metal particles (most of which have a diameter of about 100 nanometers) are polarized to produce a unique chain effect of dielectrophoresis, which will cause Aggregation results in a larger volume, and rapidly sinks under the action of gravity and intermittent application of dielectrophoresis, thereby achieving the effect of reducing the pollution of the microfiltration permeable membrane. like figure 1 shown.

[0031] All the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com