Mold structure of large double-hole pipe profile with horizontal reinforcing ribs and processing method thereof

A mold processing and reinforcing rib technology, used in metal processing equipment, metal extrusion dies, metal extrusion forming tools, etc., can solve the problems of poor product quality, low mold processing efficiency, and short mold use time, and achieve improved Service life, advanced heat treatment and surface treatment, small repair modulus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

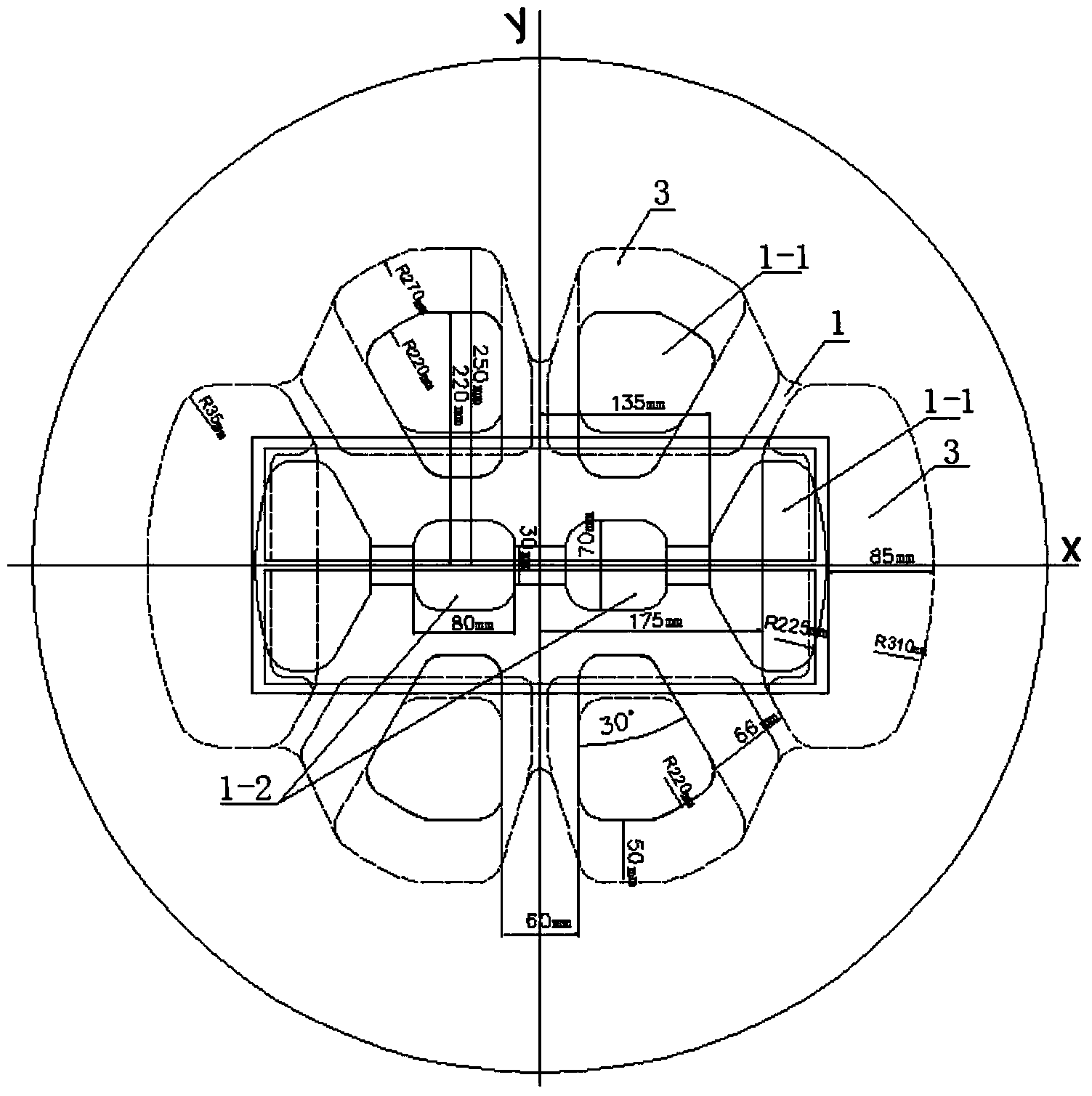

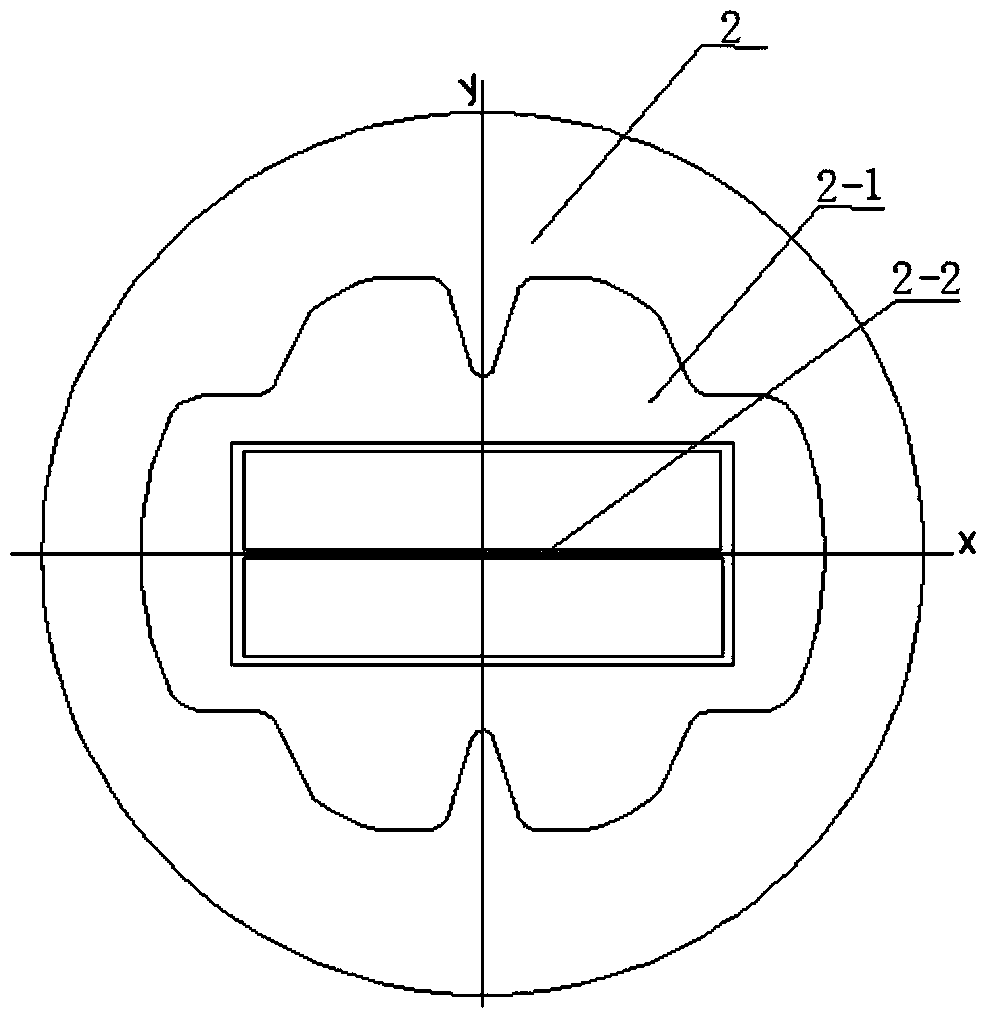

[0038] Such as figure 2 , image 3 and Figure 4 The mold structure of the large double-hole pipe profile with transverse ribs shown is used to make the mold of WYY0770 large double-hole pipe with transverse ribs. It is divided into upper mold 1 and lower mold 2, that is, a two-piece set. The upper mold 1 and the lower mold 2 are matched. The specification of the mold is φ800*500mm. The thickness of the upper mold 1 is larger than that of the lower mold 2. The upper mold 1 has a thickness of 260 mm, and the lower mold 2 has a thickness of 240 mm. Six distribution holes 1-1 are evenly distributed around the upper mold 1. The lateral width and longitudinal width of the distribution holes 1-1 are The amount is proportional to the size of the large double-hole pipe profile with transverse ribs, (see figure 2The widening part of the central distribution hole 3), the X axis represents the horizontal direction, and the Y axis represents the vertical direction. The angle is 12°,...

specific Embodiment 2

[0058] The characteristics of this embodiment are: the lateral width of the distribution hole is 23°, and the width is 150mm; the Y-axis of the distribution hole is laterally wide, the width is 12°, and the width At 800mm, other features are the same as those in Embodiment 1.

specific Embodiment 3

[0059] The characteristics of this embodiment are: the X-axis of the distribution hole is longitudinally widened, the widening angle is 23°, and the widening amount is 200mm; the Y-axis of the said distribution hole is horizontally widened, and the widening angle is 12° , the amount of wide expansion is 150mm, and other characteristics are identical with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com