Solid cut tobacco dense storage and transportation system and method

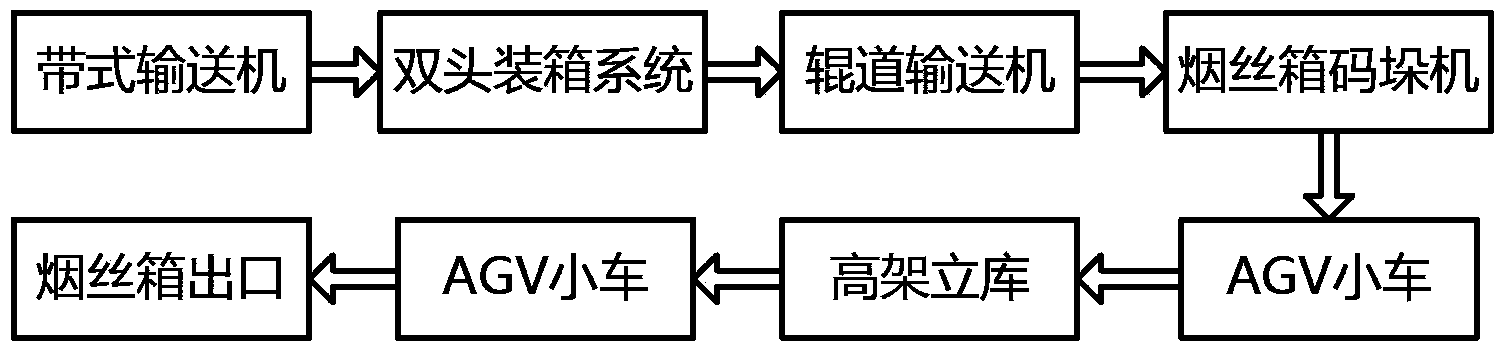

A shredded tobacco, three-dimensional technology, applied in the three-dimensional shredded tobacco intensive storage and transportation system and storage and transportation field, can solve the problems of large system occupation space and large equipment investment, and achieve the goal of simplifying storage and transportation links, reducing hardware investment costs, and improving equipment operation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

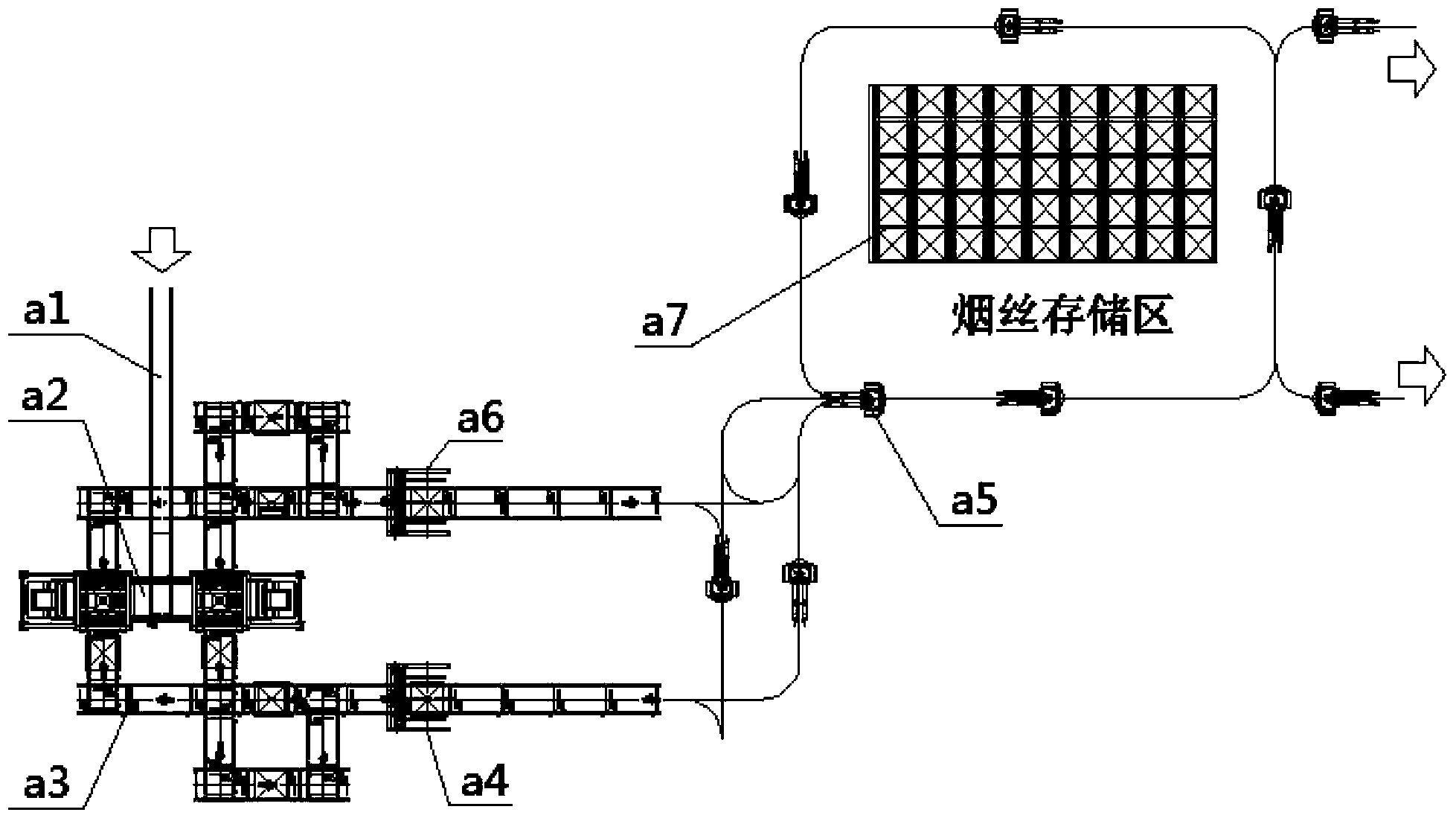

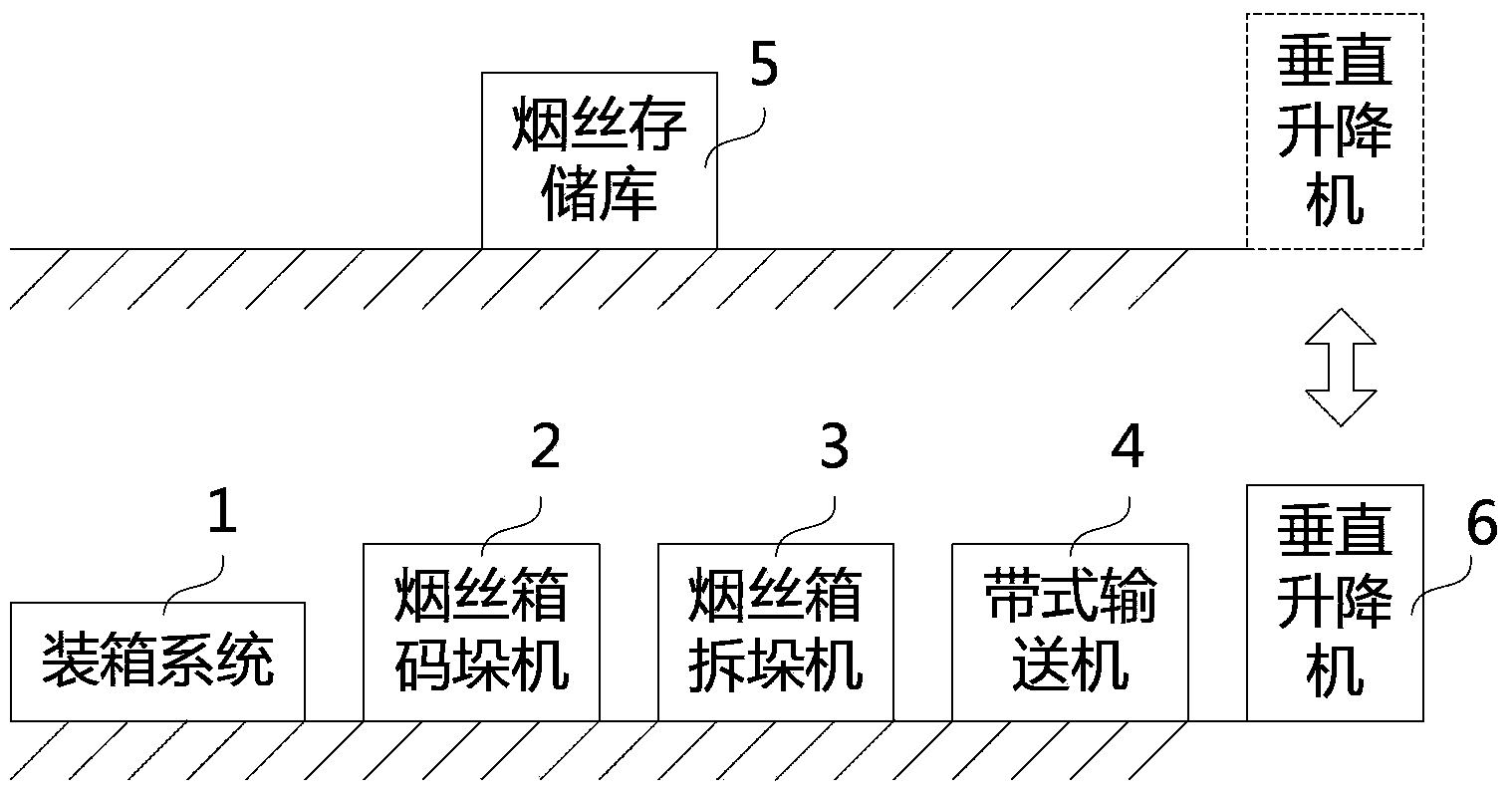

[0030] like image 3 Shown is a schematic structural view of an embodiment of the three-dimensional shredded tobacco intensive storage and transportation system of the present invention. In this embodiment, the three-dimensional shredded tobacco intensive storage and transportation system includes: a belt conveyor 4 , a packing system 1 , a shredded tobacco box palletizer 2 , a shredded tobacco box depalletizer 3 and a shredded tobacco storage warehouse 5 . And the three-dimensional shredded tobacco intensive storage and transportation system is designed as a double-layer structure, and the belt conveyor 4, packing system 1, shredded tobacco box palletizer 2 and shredded tobacco box depalletizer 3 are arranged on the same layer of the double-layered structure, and the shredded tobacco storage warehouse 5 is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com