Graphene chemical modification method

A chemical modification, graphene oxide technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of increased conductivity, limited application, loss of conductivity of graphene oxide, etc., to achieve a simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] A typical chemical modification method of hydrophilic graphene G-JM600 comprises the following steps:

[0086] Configure 1.0mg / mL graphene oxide aqueous solution, and put it in at a ratio of 13.0g per gram of graphene oxide M-600, use 1M NaOH to adjust the pH value to 11, reflux reaction at 100°C for 4 hours, after cooling to room temperature, add 1M HCl to it to adjust the pH value of the system to 3, and wash the obtained precipitate with water until neutral, that is have to M-600 surface modified graphene functional material G-JM600.

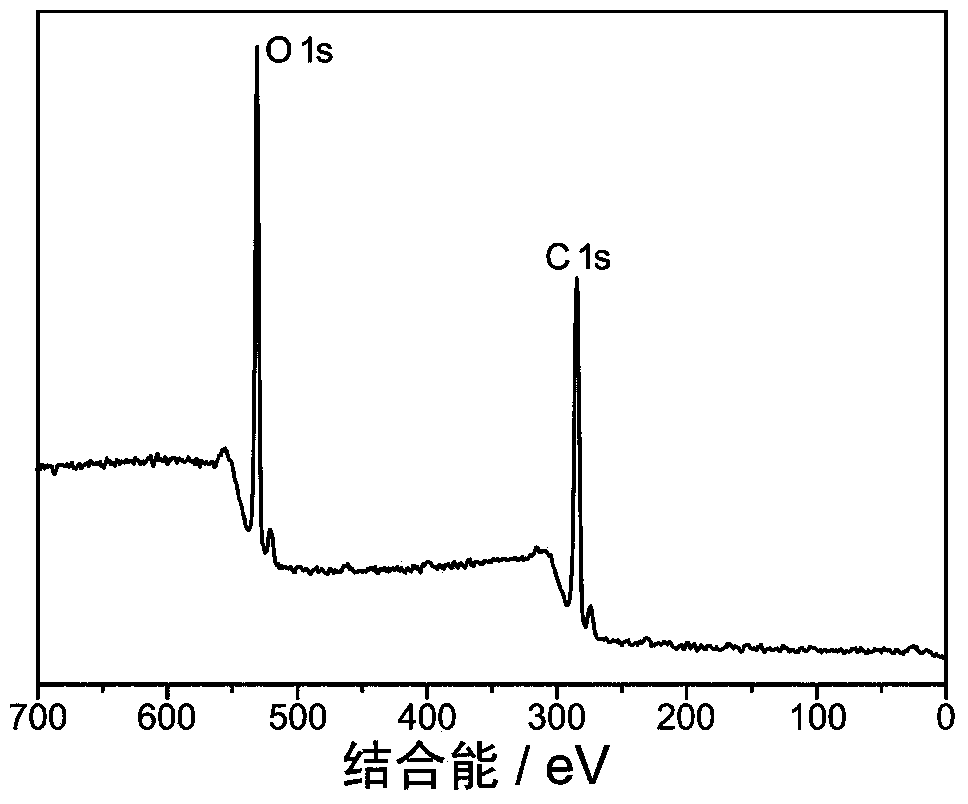

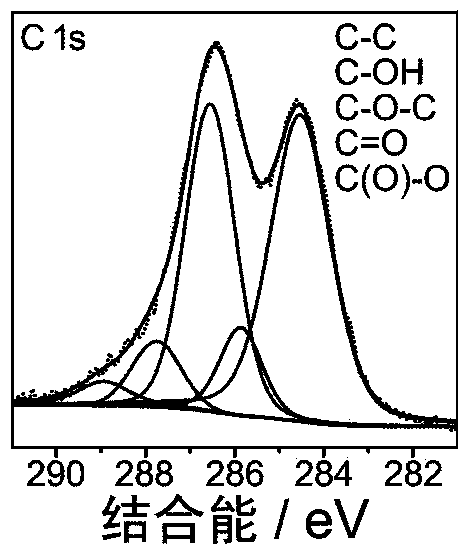

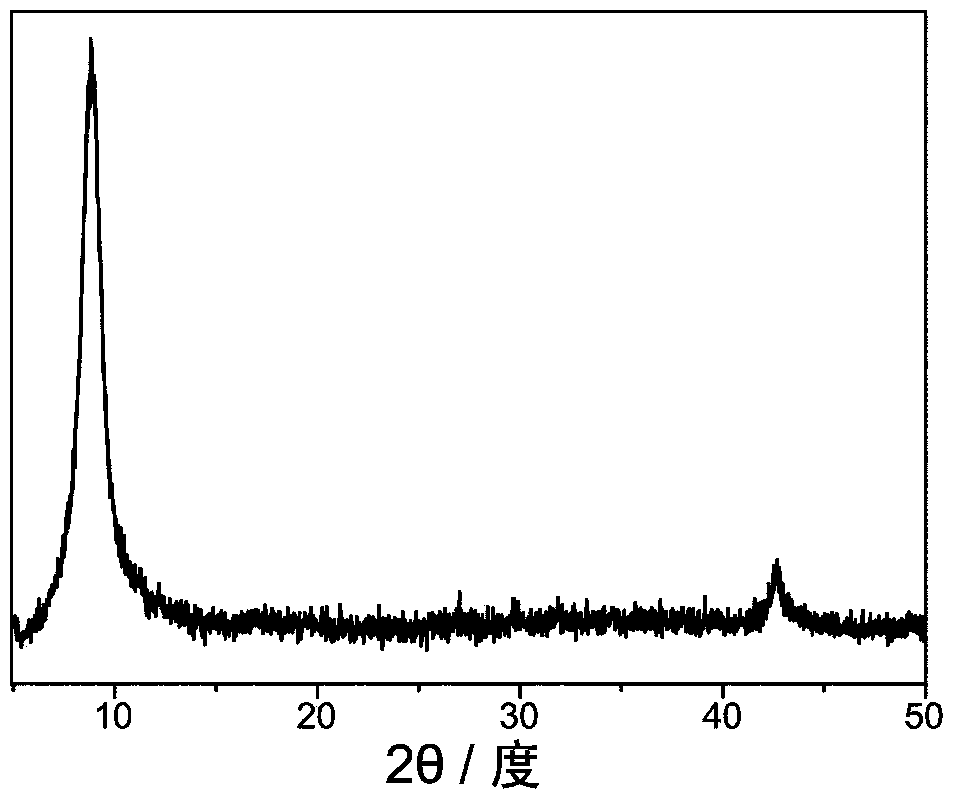

[0087] The characterization results of relevant EA, XPS, XRD, FT-IR, and Raman show that M-600 is well modified on the surface of graphene, with a surface modification degree of about 8%.

[0088] The solubility test shows that the graphene functional material G-JM600 has good hydrophilicity and can be well dispersed in water.

[0089] Table 2. EA analysis results of G-JM600.

[0090]

[0091] Comparing the EA analysis result...

Embodiment 2

[0098] A typical chemical modification method of water-soluble graphene G-JM1000 comprises the following steps:

[0099] Prepare a 1.0mg / mL graphene oxide aqueous solution, and put it in at a ratio of 22.0g per gram of graphene oxide M-1000, use 1M NaOH to adjust the pH value to 11, reflux reaction at 100°C for 6 hours, after cooling to room temperature, add 1M HCl to it to adjust the pH value of the system to 3, and wash the obtained precipitate with water until neutral, that is have to M-1000 surface modified graphene functional material G-JM1000.

[0100] The characterization results of relevant EA, XPS, XRD, FT-IR, and Raman show that M-1000 is well modified on the graphene surface, with a surface modification degree of about 8%.

[0101] The solubility test shows that the graphene functional material G-JM1000 has good water solubility.

[0102] Table 3. EA analysis results of G-JM1000.

[0103]

[0104] Comparing the EA analysis results of G-JM1000 in the table...

Embodiment 3

[0111] The chemical modification method of a typical water-soluble graphene G-JM2070 comprises the following steps:

[0112] Prepare a 1.0mg / mL graphene oxide aqueous solution, and put it in at a ratio of 44.0g per gram of graphene oxide M-2070, use 1M NaOH to adjust the pH value to 11, reflux reaction at 100°C for 8 hours, after cooling to room temperature, add 1M HCl to it to adjust the pH value of the system to 3, and wash the obtained precipitate with water until neutral, that is have to M-2070 surface modified graphene functional material G-JM2070.

[0113] The characterization results of relevant EA, XPS, XRD, FT-IR, and Raman show that M-2070 is well modified on the graphene surface, with a surface modification degree of about 8%.

[0114] The solubility test shows that the graphene functional material G-JM2070 has excellent water solubility, and can also be dissolved in various organic solvents such as THF, DMF, alcohols, and ketones.

[0115] Table 4. EA analys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com