Method for carrying out synchronous nitrification treatment and denitrification treatment on percolate by using mineralized refuse reaction bed

A technology of mineralized garbage and synchronous nitrification, applied in the field of environmental protection, can solve the problems of low total nitrogen removal rate, low total nitrogen removal rate, high total nitrogen removal rate, etc., achieve good environmental ecological significance and economic benefits, and low treatment cost , good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The mineralized waste and leachate in this example were all taken from Chongkou Landfill in Guilin City.

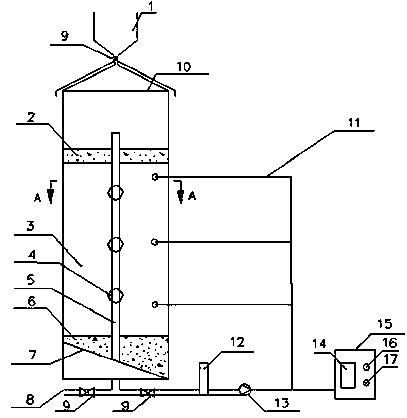

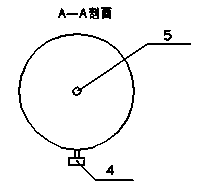

[0022] (1) A device for synchronous nitrification and denitrification treatment of leachate in a mineralized waste reaction bed is provided, including a mineralized waste reaction bed and an aeration device, wherein the mineralized waste reaction bed is the main body of the device, and a solid sampling port is arranged on its surface 4. A water outlet sampling port 8 and an aeration pipe are installed at the lower part of the mineralized waste reaction bed, and a valve 9 is installed on the water outlet sampling port 8 and the aeration pipe. The aeration pipe is connected to the rotameter 12, and the rotameter 12 is connected to the air pump 13 , the air pump 13 is connected with the control box 15 through the line, and the temperature display 14, the aeration switch 16 and the temperature switch 17 are set on the control box 15; The top of the top is sealed, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com