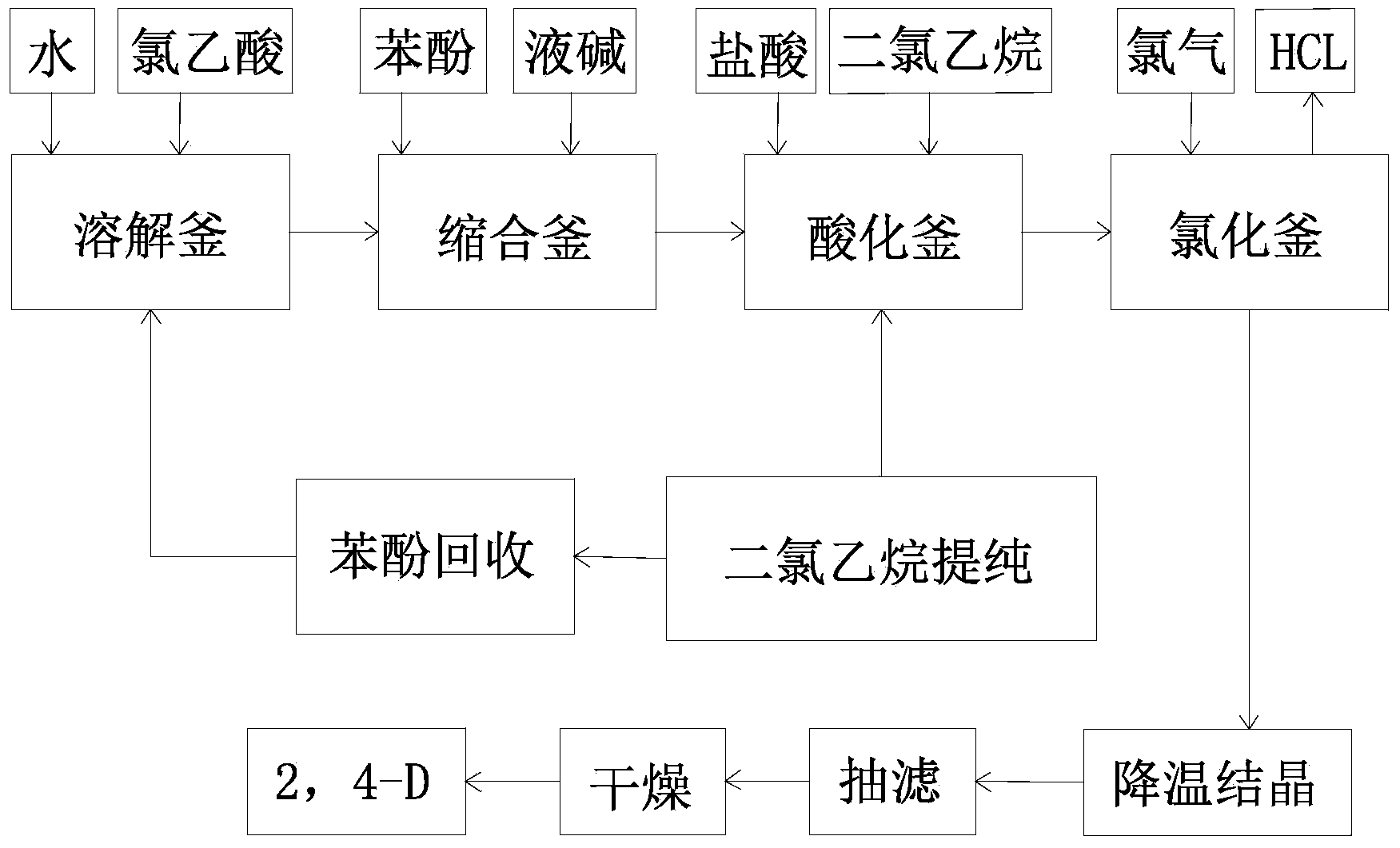

Preparation method and device of 2,4-dichlorphenoxyacetic acid

A dichlorophenoxyacetic acid and preparation device technology, which is applied in the direction of carboxylate preparation, organic compound preparation, feeding device, etc., can solve the problems of high cost, low content, serious pollution, etc., and achieve the reduction of waste water and easy treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) First, put 475L of water into the dissolution tank and start stirring, then put in 475kg of chloroacetic acid weighed in 3 times, control the temperature at 10°C, stir for 30 minutes, then transfer to the high level tank of chloroacetic acid to obtain the quality The percentage concentration is 50% aqueous solution of chloroacetic acid;

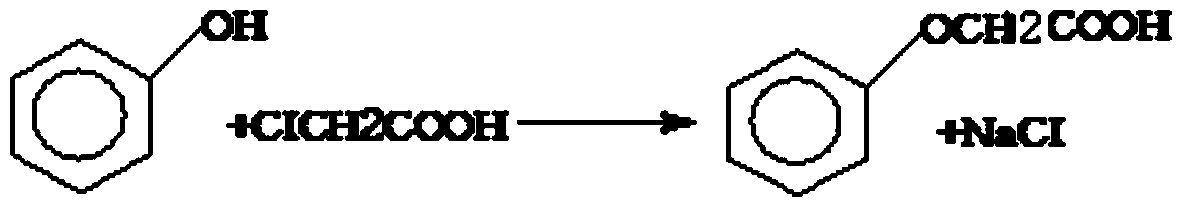

[0027] (2) Put 400kg of phenol and 550kg of liquid caustic soda into the condensation kettle, and react at a temperature of 70°C for 30 minutes to obtain a phenol sodium salt solution, and then dropwise add 720kg of liquid caustic soda with a mass percentage concentration of 25% to it at the same time With 900kg of chloroacetic acid aqueous solution obtained in step (1), react while adding dropwise, the reaction temperature is 88°C, the pH value is controlled at 9, the dropping time is 1.5 hours, and the holding time is 1 hour;

[0028] (3) First transfer the above-mentioned reacted solution to an acidification kettle, adjust the p...

Embodiment 2

[0031] (1) First, put 241L of water into the dissolution tank and start stirring, then add 723kg of chloroacetic acid weighed in 6 times, control the temperature at 20 degrees, stir for 40 minutes, then transfer to the high level tank of chloroacetic acid to obtain the quality The percentage concentration is 75% aqueous solution of chloroacetic acid;

[0032] (2) Put 600kg of phenol and 797kg of liquid caustic soda into the condensation kettle, and react for 40 minutes at a temperature of 75°C to obtain a phenol sodium salt solution, and then dropwise add 956kg of liquid caustic soda with a mass percentage concentration of 27.5% to it at the same time With 1423kg of the aqueous solution of chloroacetic acid obtained in step (1), react while adding dropwise, the reaction temperature is 95°C, the pH value is controlled at 10, the dropping time is 3 hours, and the holding time is 3 hours;

[0033] (3) First transfer the above-mentioned reacted solution to the acidification kettle...

Embodiment 3

[0036] (1) First, put 237.5L of water into the dissolution tank and start stirring, then add 950kg of chloroacetic acid weighed in 8 times, control the temperature at 30°C, stir for 45 minutes, then transfer to the high level tank of chloroacetic acid to obtain Mass percent concentration is 80% chloroacetic acid aqueous solution;

[0037] (2) Put 800kg of phenol and 1,063kg of liquid caustic soda into the condensation kettle, and react for 45 minutes at a temperature of 80°C to obtain a phenol sodium salt solution, and then add 1,257kg of liquid caustic soda with a mass percentage concentration of 30% to it at the same time With 1900kg of aqueous solution of chloroacetic acid obtained in step (1), react while adding dropwise, the reaction temperature is 102°C, the pH value is controlled at 11, the time for dropping is 5 hours, and the temperature is kept for 5 hours;

[0038] (3) First transfer the above-mentioned reacted solution to the acidification kettle, adjust the pH val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com