Silicon wafer cutting fluid and preparation method thereof

A silicon chip cutting fluid and solution technology, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of filter bag clogging, increased production costs, scrapping of the entire knife mortar, etc., to reduce pH value drop and increase storage time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

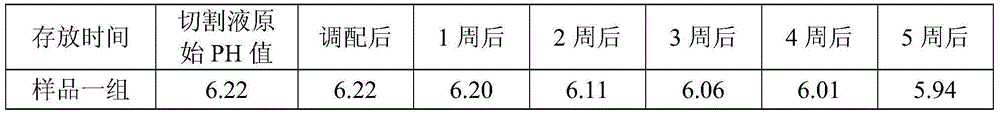

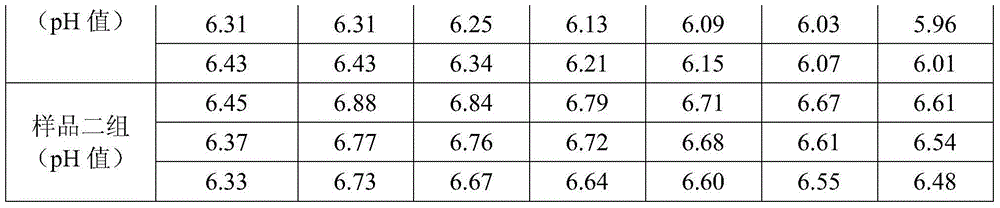

Examples

Embodiment 1

[0033] A kind of silicon chip cutting liquid, it is mainly made up of following raw material by weight percentage:

[0034] Cutting fluid commonly used raw materials 99wt%

[0035] Formamide solution 1wt%.

[0036] Wherein, the concentration of the formamide solution is 99.50%.

[0037] Its preparation method is:

[0038] 1) First, calculate the required amount of formamide solution according to the weight of silicon wafer cutting fluid to be prepared;

[0039] 2) Stir the silicon wafer cutting solution first, slowly add the formamide solution during the stirring process, wait for all the solution to be poured and then stir evenly for 5 minutes;

[0040] 3) The prepared silicon wafer cutting fluid should be immediately stored in cans and sealed to avoid long-term exposure to the air.

Embodiment 2

[0042] A kind of silicon chip cutting liquid, it is mainly made up of following raw material by weight percentage:

[0043] Cutting fluid commonly used raw materials 80wt%

[0044] Formamide solution 20wt%

[0045] Wherein, the concentration of the formamide solution is 99.50%.

[0046] Its preparation method is the same as Example 1, the difference is that the stirring time is 3min.

Embodiment 3

[0048] A kind of silicon chip cutting liquid, it is mainly made up of following raw material by weight percentage:

[0049] Cutting fluid commonly used raw materials 95wt%

[0050] Formamide solution 5wt%

[0051] Wherein, the concentration of the formamide solution is 99.50%.

[0052] Its preparation method is the same as Example 1, the difference is that the stirring time is 15min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com