Continuous air pressure sintering method for copper-based composite material friction block

A copper-based composite material and air pressure sintering technology, which is applied in the field of train braking systems, can solve problems such as the inability to achieve continuous sintering, and achieve the effects of facilitating the friction coefficient, overcoming fluctuations and differences, and stabilizing the friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

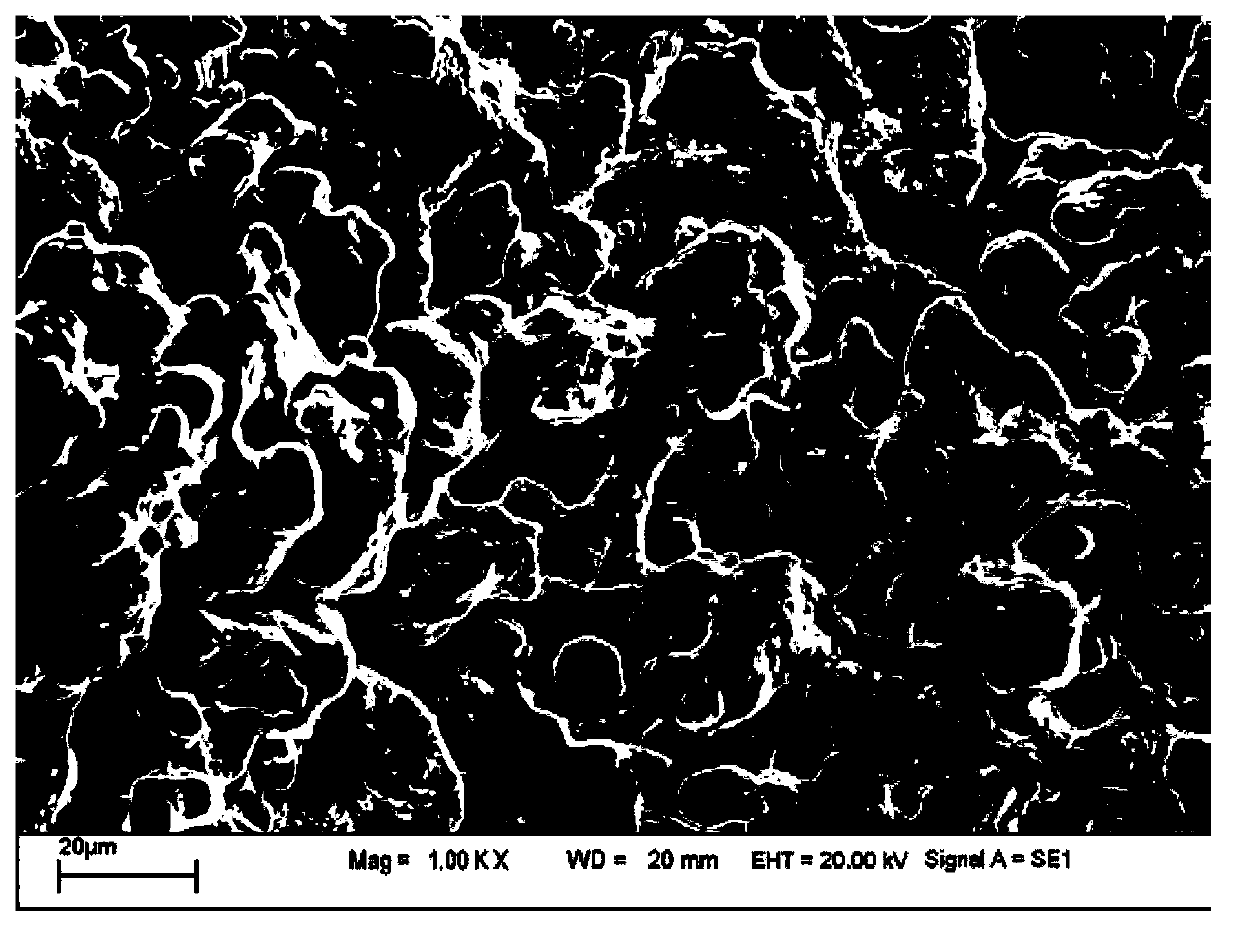

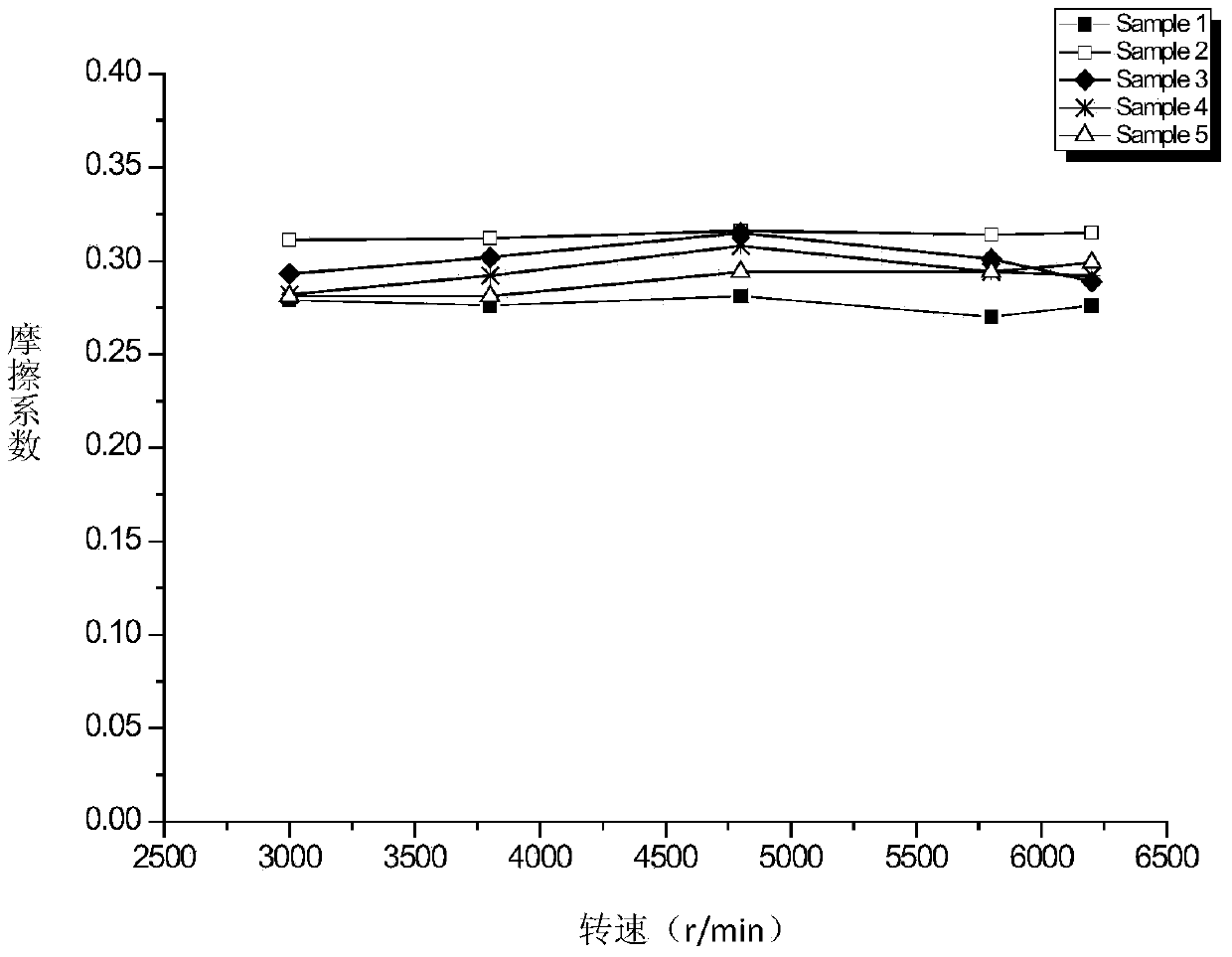

Embodiment 1

[0014] Weigh copper powder, iron powder, flake graphite, molybdenum disulfide, alumina, and chromite according to the formula requirements, and the ratio of copper to iron is 6:1. After the ingredients are uniformly mixed and cold pressed into shape, it is ready for continuous gas pressure sintering. Adjust the operating speed of the continuous sintering equipment to 35mm / min, the sintering temperature to 780°C, and the holding time to 180min. Adjust the gas pressure in the furnace chamber to 0.5MPa, which is composed of hydrogen and nitrogen in a volume ratio of 1:2. Place the sample and the transmission device in such a way that the horizontal distance between the samples is 1.5 times the cross-sectional area of the sample, and the vertical distance is 2 times the cross-sectional area of the sample. The sample is sintered into the furnace with the transmission device. After passing through the preheating zone, low temperature zone, high temperature zone, and cooling zon...

Embodiment 2

[0016] Weigh copper powder, iron powder, flake graphite, molybdenum disulfide, alumina, and chromite according to the formula requirements, and the ratio of copper to iron is 6:1. After the ingredients are uniformly mixed and cold pressed into shape, it is ready for continuous gas pressure sintering. Adjust the operating speed of the continuous sintering equipment to 45mm / min, the sintering temperature to 890°C, and the holding time to 120min. Adjust the gas pressure in the furnace chamber to 1MPa, which is composed of hydrogen and nitrogen in a volume ratio of 1:4. Place the sample and the transmission device in such a way that the horizontal distance between the samples is 1.5 times the cross-sectional area of the sample, and the vertical distance is 2 times the cross-sectional area of the sample. The sample is sintered into the furnace with the transmission device. After passing through the preheating zone, low temperature zone, high temperature zone, and cooling zone ...

Embodiment 3

[0018] Weigh copper powder, iron powder, flake graphite, molybdenum disulfide, alumina, and chromite according to the formula requirements, and the ratio of copper to iron is 4:1. After the ingredients are uniformly mixed and cold pressed into shape, it is ready for continuous gas pressure sintering. Adjust the operating speed of the continuous sintering equipment to 80mm / min, the sintering temperature to 960°C, and the holding time to 60min. Adjust the gas pressure in the furnace chamber to 1MPa, which is composed of hydrogen and nitrogen in a volume ratio of 1:5. Place the sample and the transmission device in such a way that the horizontal distance between the samples is 1.5 times the cross-sectional area of the sample, and the vertical distance is 2 times the cross-sectional area of the sample. The sample is sintered into the furnace with the transmission device. After passing through the preheating zone, low temperature zone, high temperature zone, and cooling zone i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com