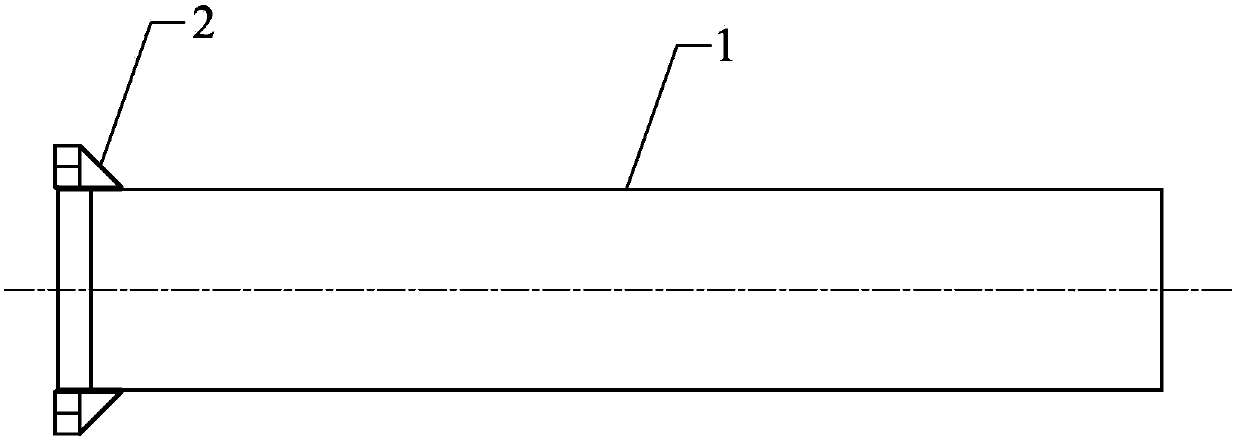

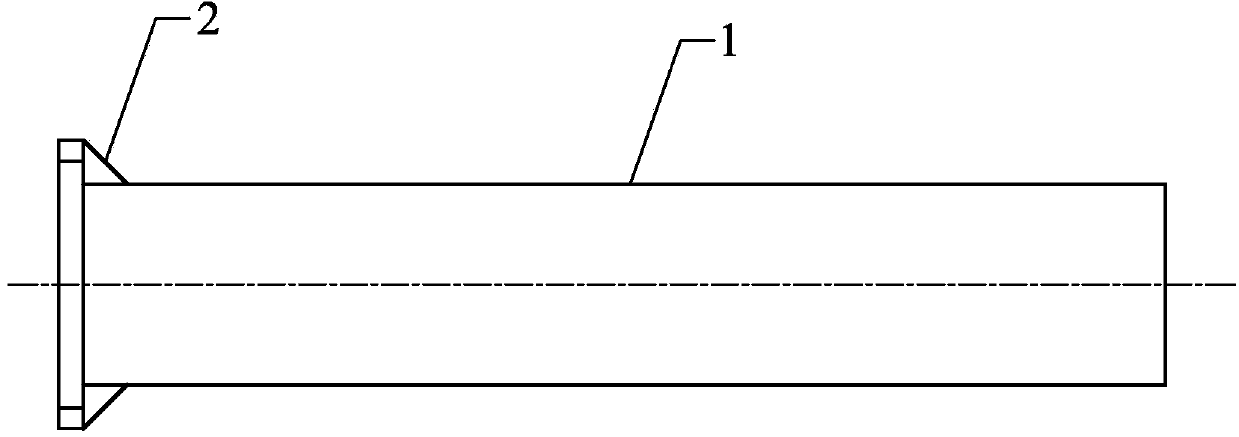

Spheroidal graphite cast iron foundation pile pipe and preparation process thereof

A ductile iron and preparation process technology, which is applied in basic structural engineering, manufacturing tools, sheet pile walls, etc., can solve the problems of long construction time and high labor intensity, and achieve the effects of short construction period, low labor intensity and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A ductile iron foundation pile pipe and a preparation process thereof, comprising the following steps:

[0035] ①Preparation before casting pipe: including molten iron preparation, spheroidizing treatment and spraying paint on the inner wall of the pipe mold;

[0036] The molten iron is prepared by heating the molten iron with an intermediate frequency electric furnace, and the temperature of the molten iron is raised to 1460°C-1500°C. The mass fraction of the main chemical components in the molten iron is as follows:

[0037] C: 2.9-3.2%, Si: 1.4-1.6%, Mn≤0.5%, Ti≤0.04%, P≤0.06%, S≤0.020%;

[0038] The spheroidizing treatment is to spheroidize the molten iron in one of the ways of the flushing method, the wire feeding spheroidization method or the pure magnesium spheroidization method. After the spheroidization, the mass fraction of the main chemical components in the molten iron is as follows:

[0039] C: 3.0-3.3%, Si: 1.9-2.4%, Mn ≤ 0.5%, P ≤ 0.06%, S ≤ 0.02%, Mg: 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com