Corrosion-resistant steel for high-Nb crude oil cargo ship cabin base plate

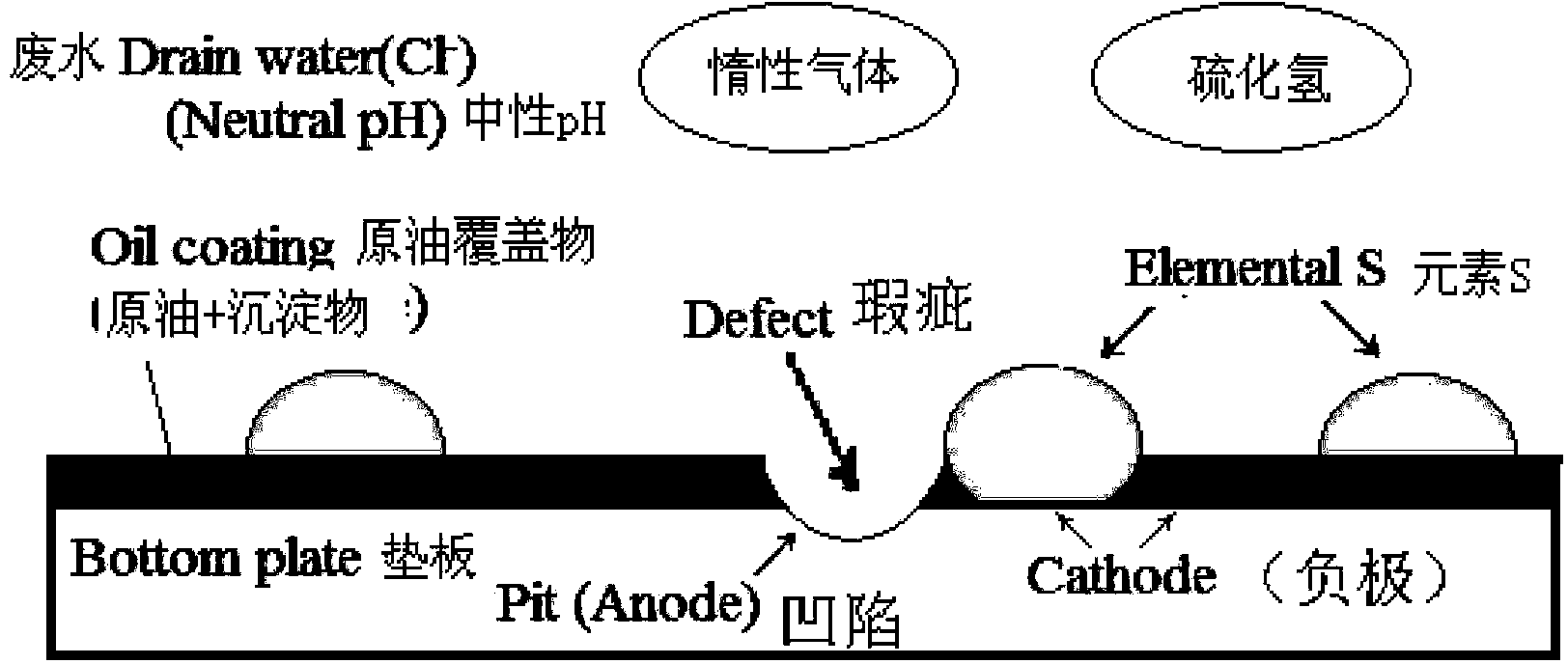

A technology for corrosion-resistant steel and crude oil, which is applied in the field of steel for cargo ship floor plates, can solve the problems of coating damage and corrosion, high maintenance cost, high cost, etc., and achieves the effect of simple preparation process and enhanced local corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

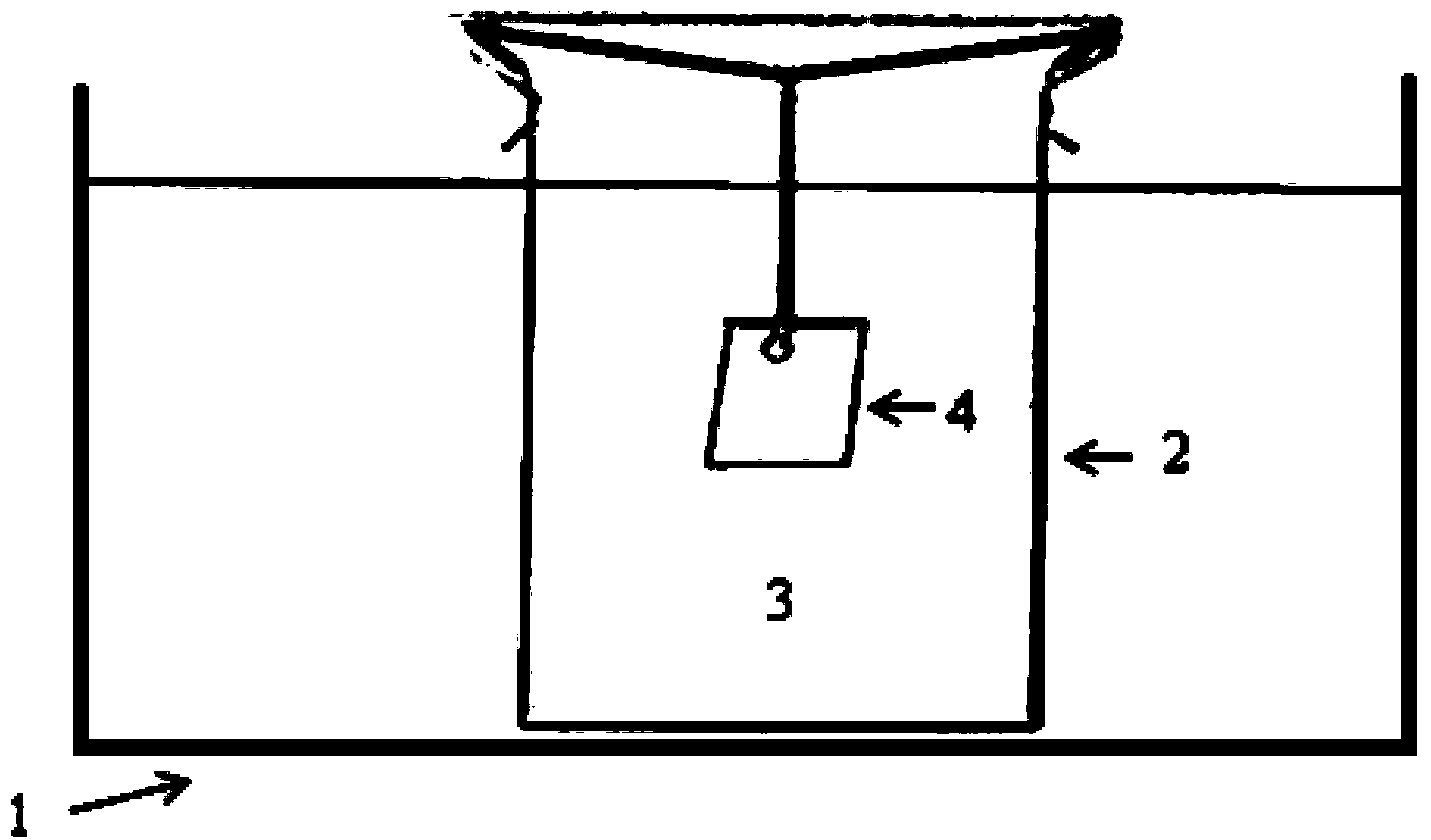

[0036] Steels with various compositions as shown in Table 1 were smelted in a vacuum induction furnace. After these billets were reheated to 1200°C, they were rolled at 1100°C and finished at 850°C to form steel plates. Cut out a rectangular corrosion coupon with a size of 50mm×40mm×5mm from the steel plate and put it in figure 1 In the test device shown, keep the temperature at 30°C and soak for 72 hours. The test device is a constant temperature tank 1, a beaker 2, a corrosion solution 3 with pH = 0.85 and 10% NaCl in the beaker, and a corrosion coupon 4 suspended and immersed in the corrosive solution. This test method is a test method used to evaluate the corrosion resistance of the tanker's corrosion-resistant bottom plate stipulated in the "Performance Standards for Corrosion-Resistance Measures for Substitute Coatings for Cargo Oil Tanks of Crude Cargo Tanks" issued by the International Maritime Association. After the test, the samples were taken out, the corrosion wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com