Cathodic protection system for storage tank outer bottom based on thin-plate zinc alloy anode

A cathodic protection and zinc alloy technology, which is applied in the field of corrosion and protection of oil and gas storage and transportation systems, can solve the problems of small output current, waste of power supply capacity, high resistivity, etc., and achieve the effect of extending the protection period and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

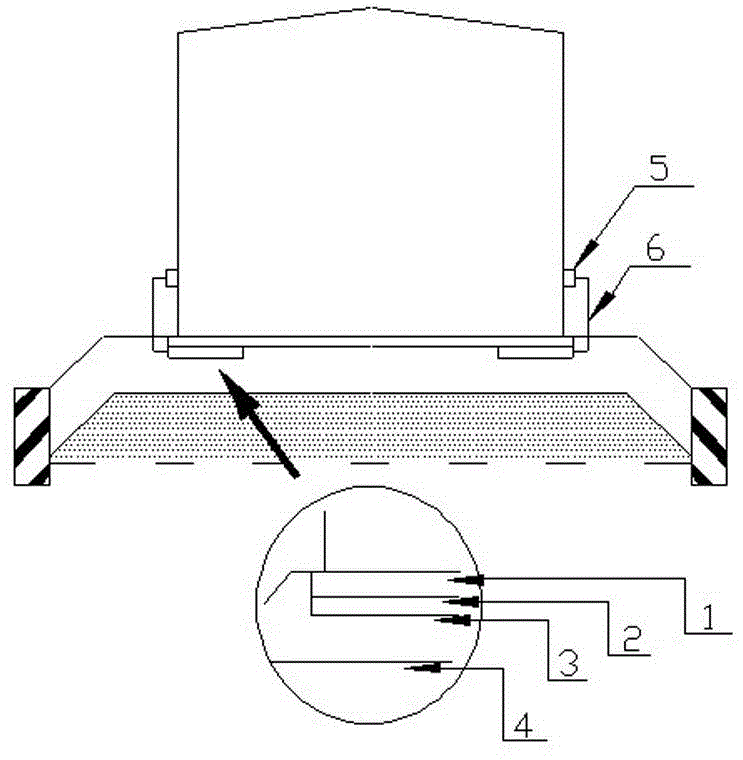

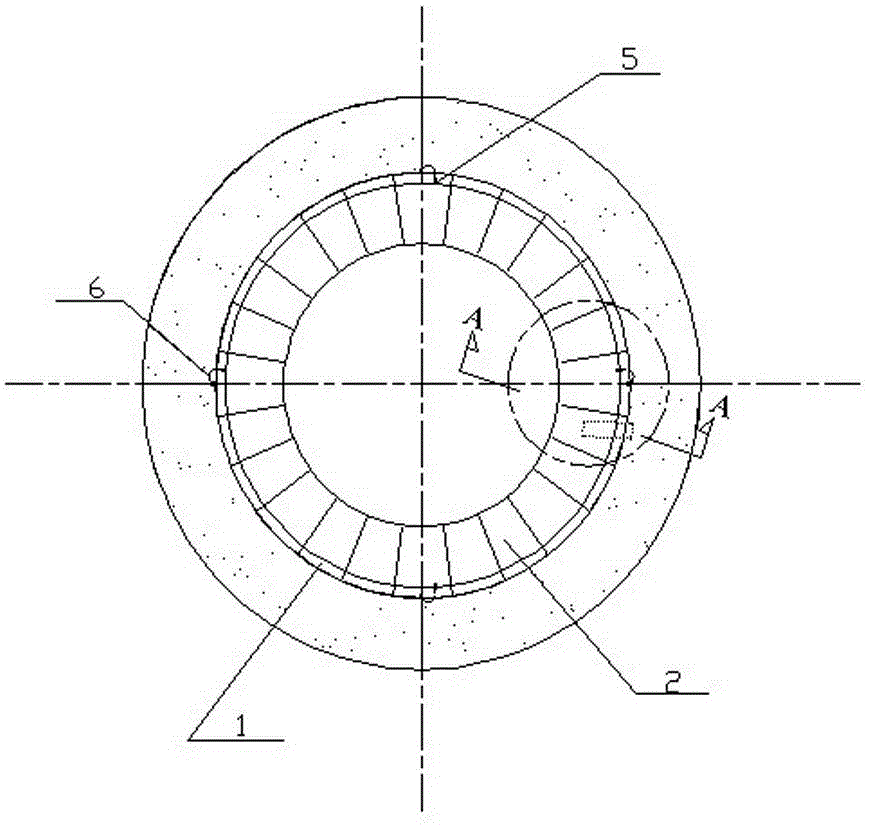

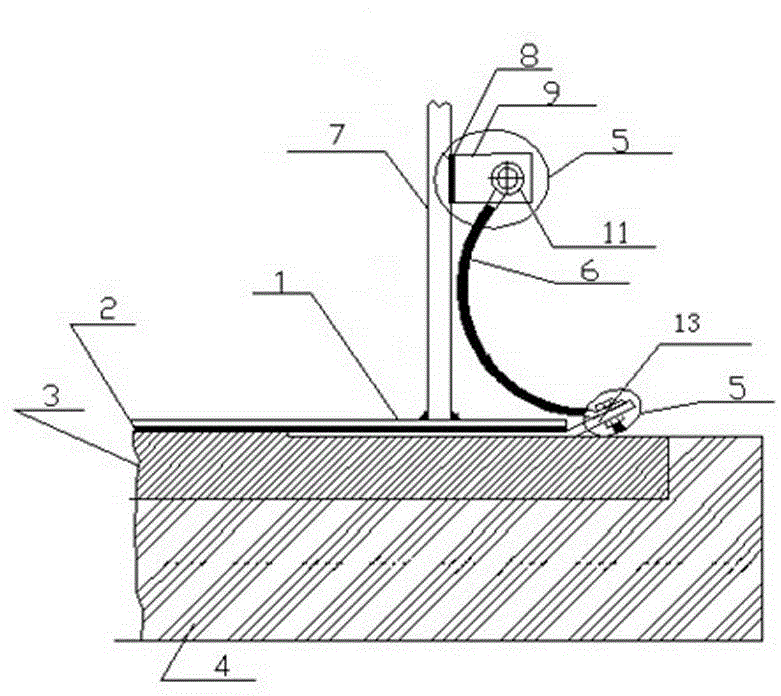

[0022] see Figure 1 to Figure 4 , the present invention relates to a cathodic protection system for the outer bottom of a storage tank based on a sheet-shaped zinc alloy anode. The cathodic protection system for the outer bottom of the storage tank is arranged at the bottom of the outer bottom plate (1) of the storage tank. The anode (2), asphalt sand (3) and foundation sand layer (4), the tank shell steel plate (7) and the zinc alloy sheet anode (2) are connected by cables (6).

[0023] The upper surface of the zinc alloy thin plate anode 2 is used as the working surface of the sacrificial anode, and a layer of packing material is added between the outer bottom plate 1 of the storage tank and the zinc alloy thin plate anode 2. The packing material is composed of 50% gypsum powder, 45% Composed of bentonite or diatomite and 5% sodium sulfate, in addition to limiting the formation of the surface film and preventing electroosmotic dehydration; it can also ensure uniform ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com