Hot-blast stove for drying phosphate and compound fertilizers

A hot stove and drying technology, applied in the field of phosphate fertilizer, to achieve the effect of guaranteed fuel supply, high combustion efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

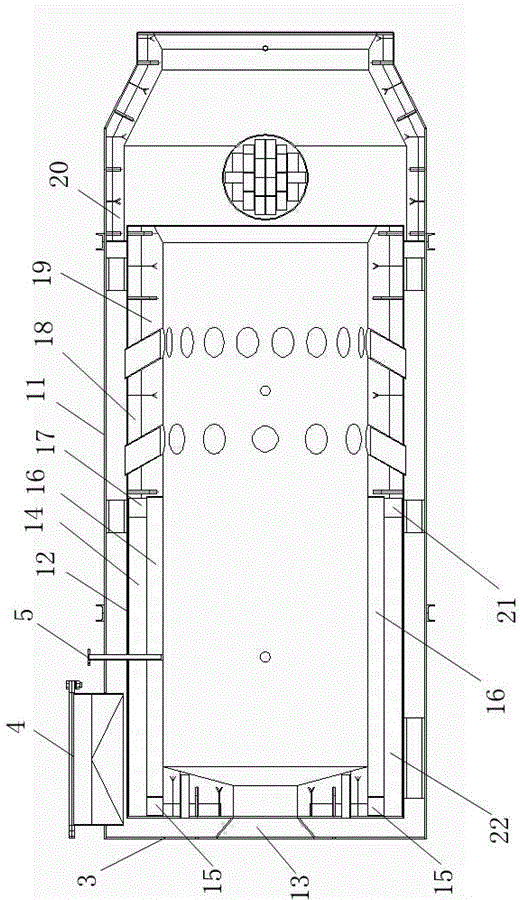

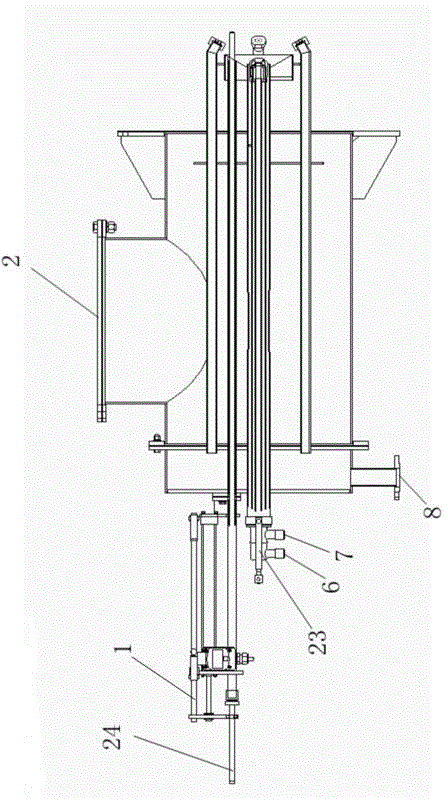

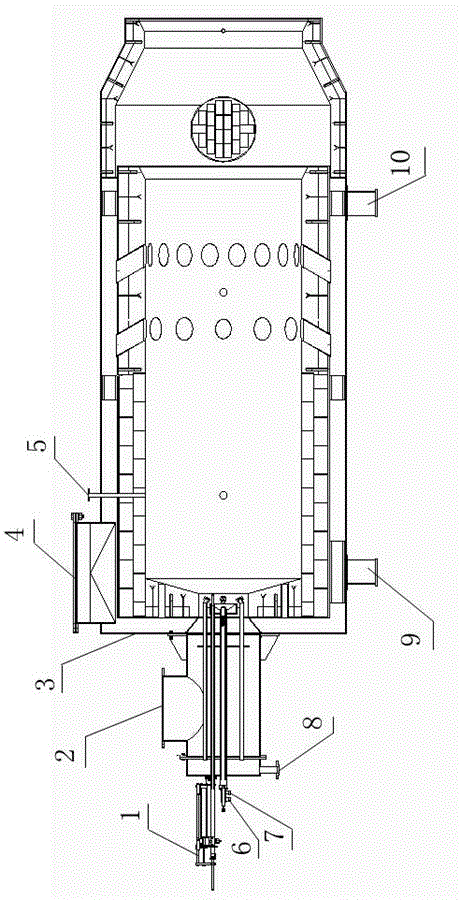

Image

Examples

Embodiment Construction

[0041] The first system of Wengfu Group's powdered monoammonium phosphate (MAP) plant adopts the "neutralization slurry concentration method to produce ammonium phosphate" process, with a designed production capacity of 160,000 tons / year of powdered MAP. Main production process: forced circulation rapid ammonification evaporation neutralization reaction → neutralization slurry double-effect circulation evaporation concentration → concentrated slurry pressure spray countercurrent fluidized bed drying → powder MAP packaging.

[0042] 1. Raw coal was used as the fuel for the hot blast stove before the transformation, and the design heat load of a single hot blast stove is 1258×10 4 KJ / h, the rated standard coal consumption is 0.82t / h.

[0043] There are following problems in using coal as hot blast stove fuel:

[0044] (1) The heat exchange tubes are frequently damaged, and air leaks into the flue gas side, resulting in positive pressure combustion in the furnace, leaving a safety...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com