Optical fiber acoustic sensor and optical fiber acoustic detection method

An acoustic wave sensor, fiber grating technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc., can solve the problems of high cost, low sensitivity, complex structure, etc., and achieve the effect of high cost, high sensitivity, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

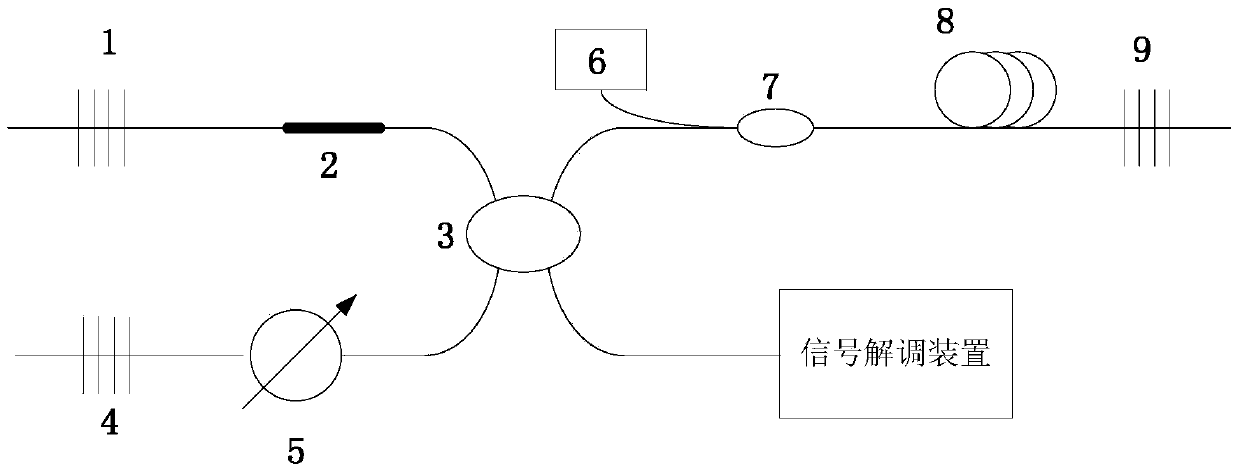

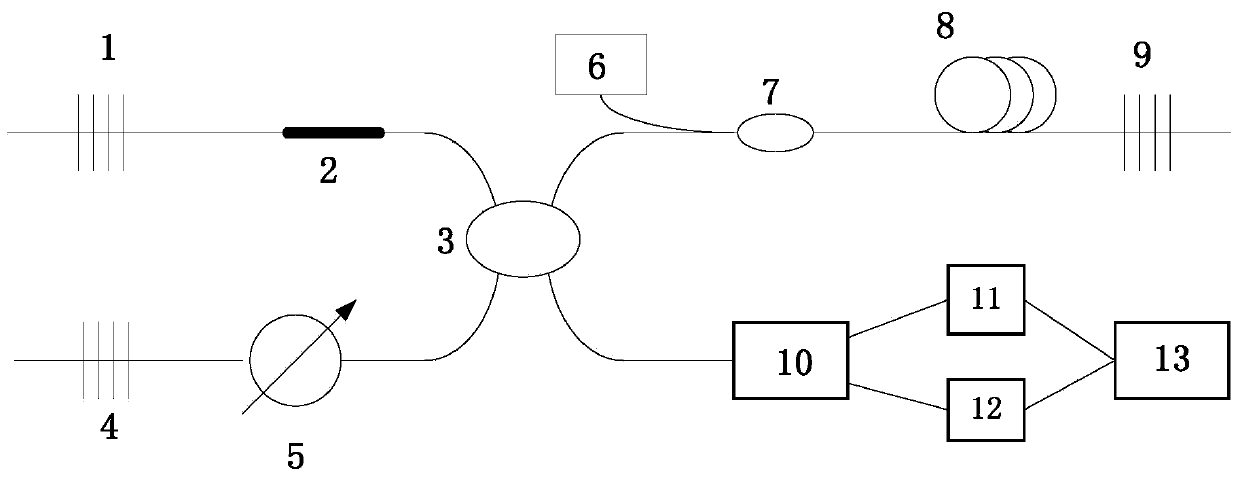

[0048] Such as image 3 As shown, the fiber optic acoustic wave sensor of this embodiment includes a first fiber grating 1 for wavelength selection; a sensing unit 2 for capturing weak acoustic signals; a coupler 3 with a power splitting ratio of 1:1, which is a transmission and the passive device for distributing signals, which have 4 ports; the second fiber grating 4 whose reflection wavelength is different from that of the first fiber grating 1 is used for wavelength selection; the tunable attenuator 5 can produce certain energy attenuation for the signal, and balance The loss of the two channels; the pump source 6 provides an excitation source for the laser; the wavelength division multiplexer 7 couples the pump light energy into the gain fiber; the gain fiber 8 provides gain for the laser; A fiber grating 1 and a second fiber grating 4 constitute the resonant cavity of the laser; a tunable optical filter 10 is used to filter out laser wavelengths; a first optical probe 11...

Embodiment 2

[0052] Such as image 3 As shown, the fiber optic acoustic wave sensor of this embodiment includes a first fiber grating 1 for wavelength selection; a sensing unit 2 for capturing weak acoustic signals; a coupler 3 with a power splitting ratio of 1:1, which is a transmission and the passive device for distributing signals, which have 4 ports; the second fiber grating 4 whose reflection wavelength is different from that of the first fiber grating 1 is used for wavelength selection; the tunable attenuator 5 can produce certain energy attenuation for the signal, and balance The loss of the two channels; the pump source 6 provides an excitation source for the laser; the wavelength division multiplexer 7 couples the pump light energy into the gain fiber; the gain fiber 8 provides gain for the laser; A fiber grating 1 and a second fiber grating 4 constitute the resonant cavity of the laser; a tunable optical filter 10 is used to filter out laser wavelengths; a first optical probe 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core diameter | aaaaa | aaaaa |

| Cladding diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com