Device and method for observing shape memory alloy tension-torsion experiment

A technology of memory alloy and experimental observation, which is applied in the direction of measuring device, testing material strength by applying stable torsion force, testing material strength by applying stable tension/pressure, etc. Special performance, high cost and other issues, to achieve the effect of convenient and fast installation and fixing, cheap implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

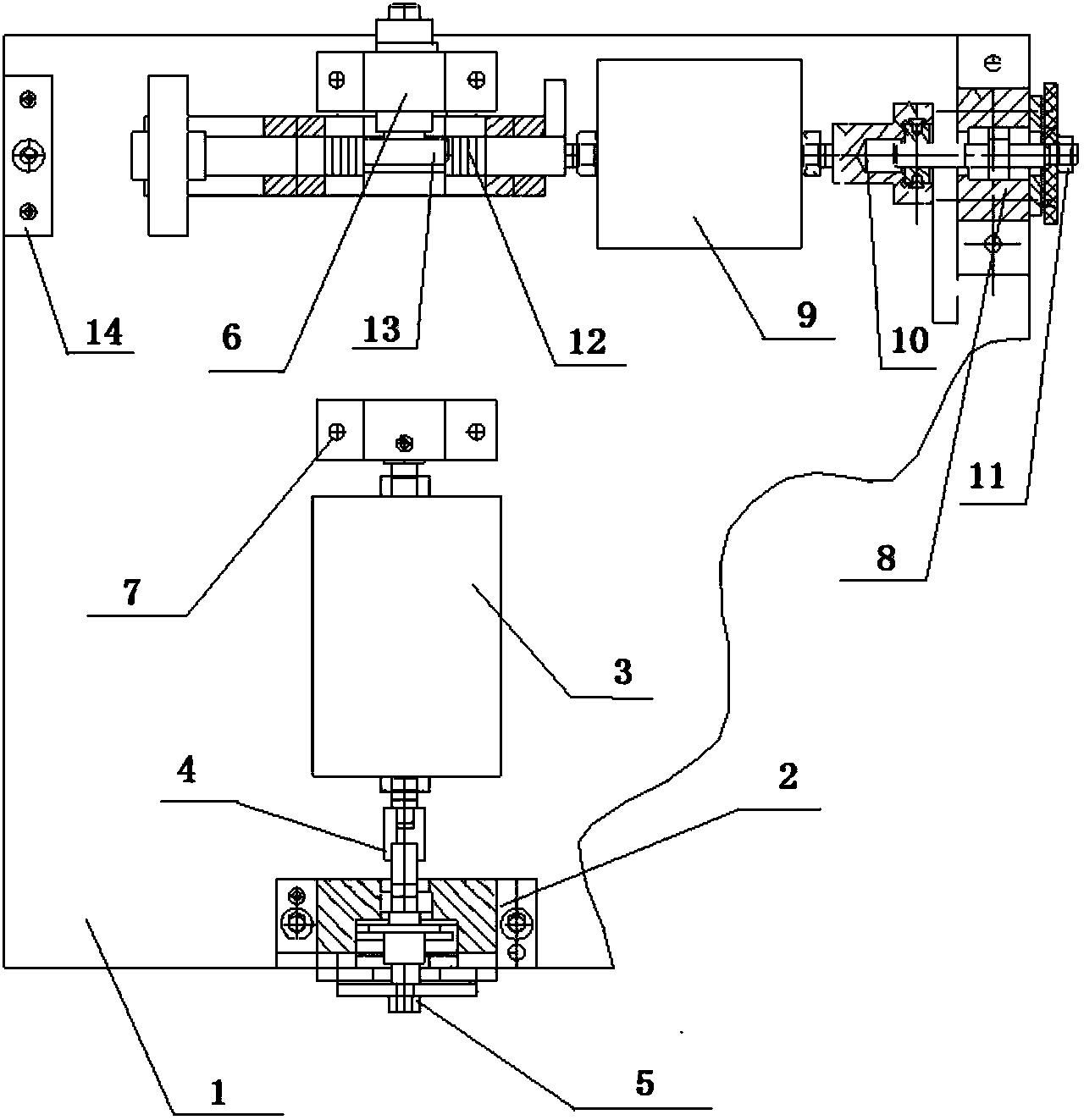

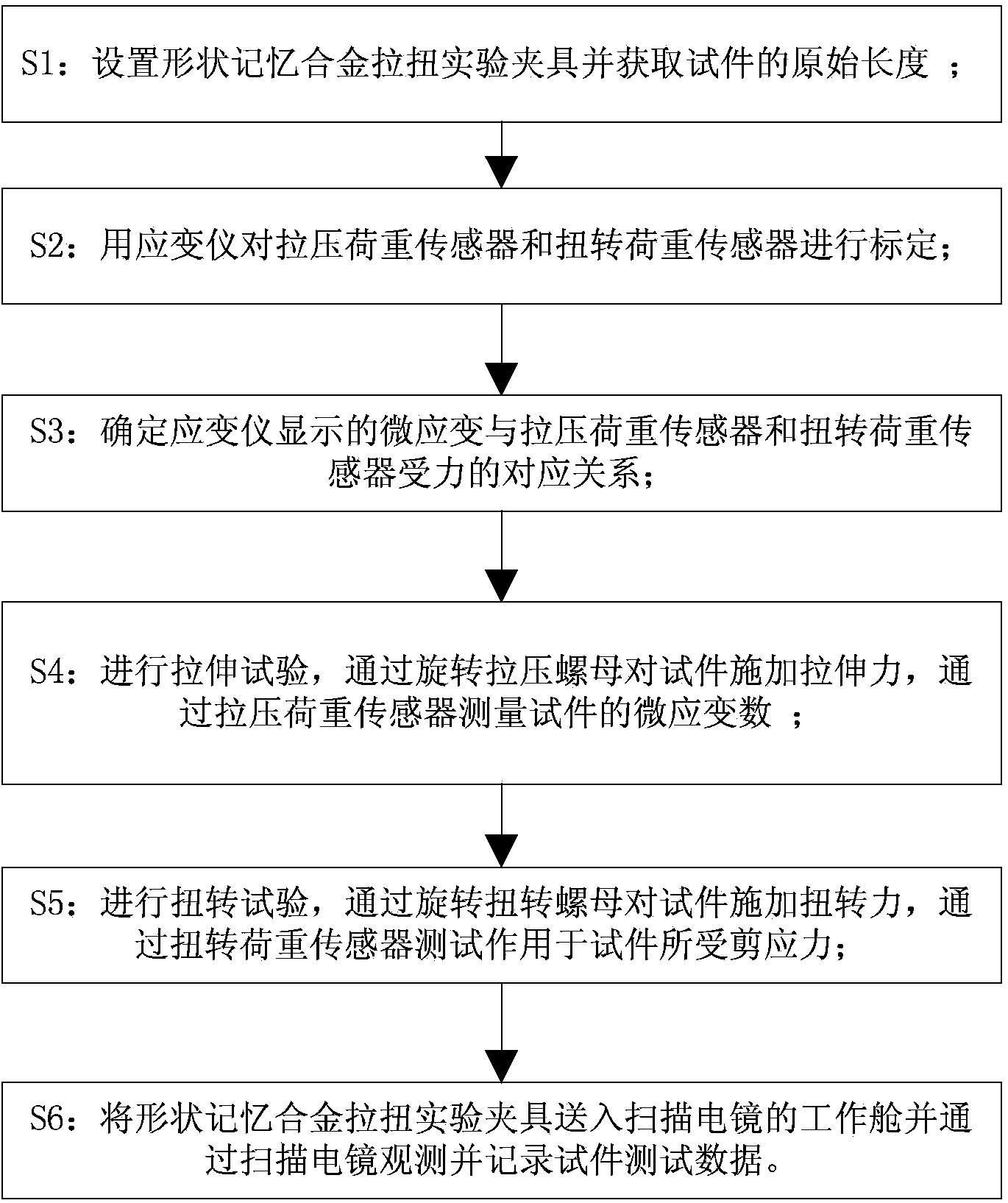

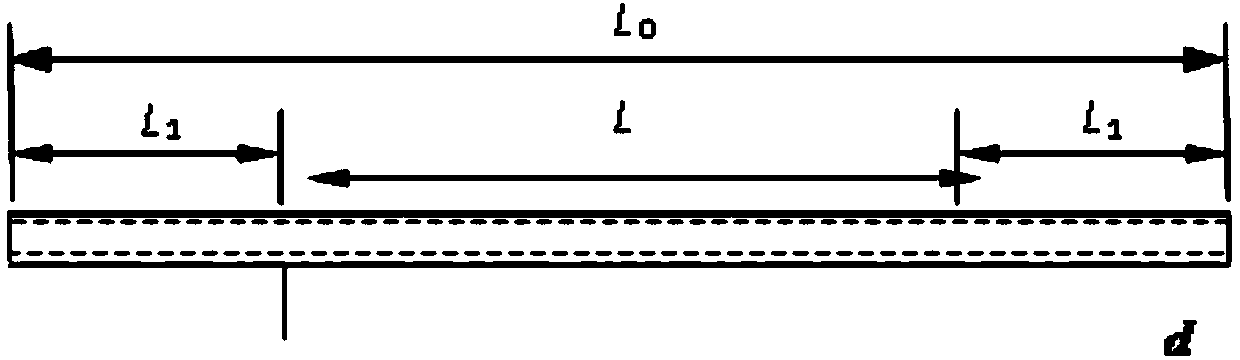

[0046] figure 1 Structural diagram of the shape memory alloy tension and torsion experimental observation device provided by the embodiment of the present invention, figure 2 The flow chart of the experimental observation method for shape memory alloy tension and torsion provided by the embodiment of the present invention, image 3 It is a longitudinal schematic diagram of the shape and size of the test piece, Figure 4It is a horizontal schematic diagram of the shape and size of the test piece, as shown in the figure: the device provided by the present invention is designed for the use of non-standard small-size test pieces. The analyzer (DSC200-PC) determines that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com