Hollow optical slip ring and optical signal transmission method thereof

A smooth ring and hollow technology, applied in the field of smooth rings, can solve the problems of high precision requirements, low connection efficiency, high cost, etc., and achieve the effect of low precision requirements, simple structure, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

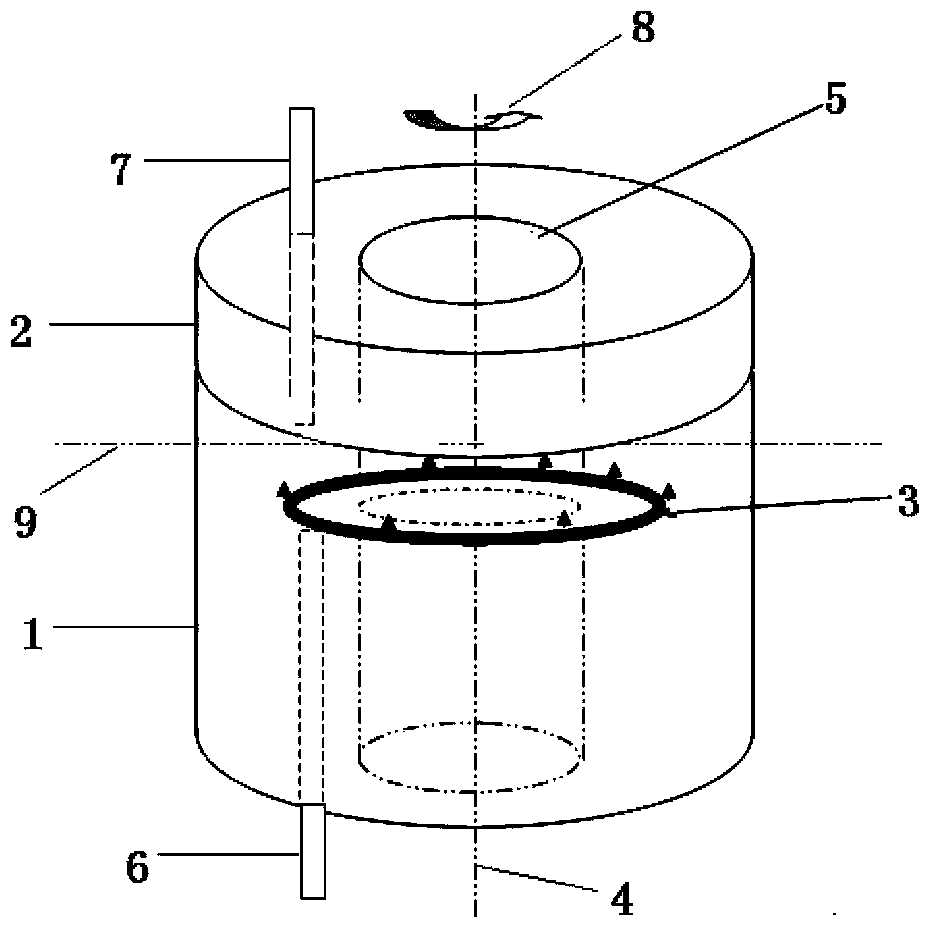

[0017] like figure 1 As shown, the hollow smooth ring provided by the present invention includes a stator 1, a rotor 2, an input fiber channel 6, an inclined fiber grating 3, and an output fiber channel 7.

[0018] The stator 1 and the rotor 2 are composed of an annular base body, the radial outer circle and the radial inner circle of the stator 1 and the rotor 2 are equal, and the axes 4 coincide with each other to form a hollow structure. The opposite surface of the annular base of the stator and the rotor is a plane, which is called the upper surface 9 of the stator.

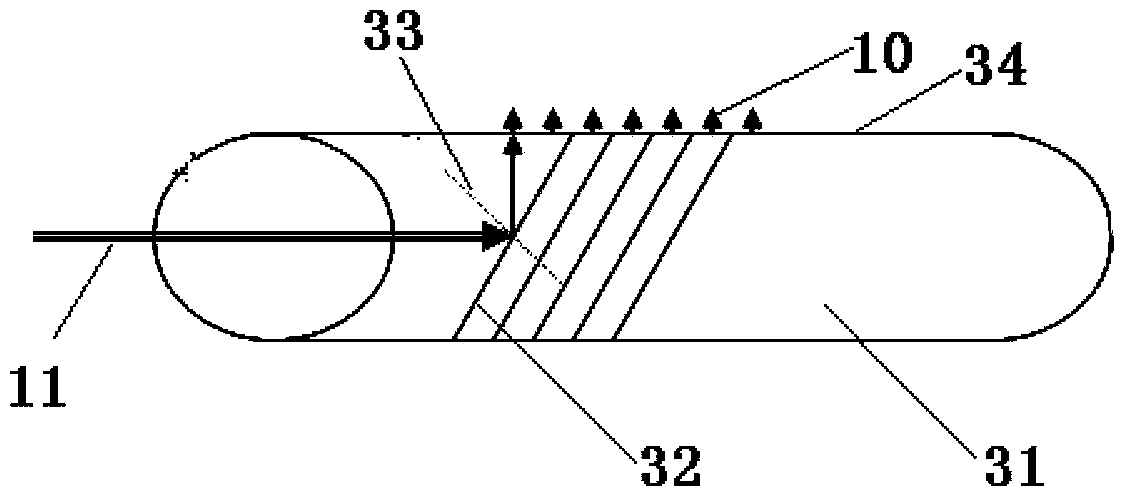

[0019] Slanted fiber grating 3 forms a ring-shaped tubular structure, partly arranged in the stator, the center line of the ring-shaped tilted fiber grating 3 coincides with the stator axis 4, and the center plane of the ring-shaped tilted fiber grating 3 is the center line of the ring-shaped tilted fiber grating 3 Vertically and intercepting the plane with the largest area of the annular inclined fiber gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com