High-reliability communication optical cable

A communication optical cable, reliability technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of difficulty in laying, poor flexibility of communication optical cable, difficult stretching, winding, bending or extrusion of optical cable, etc., and achieve excellent lateral water resistance performance and environmental protection The effect of wide temperature range and excellent longitudinal water blocking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

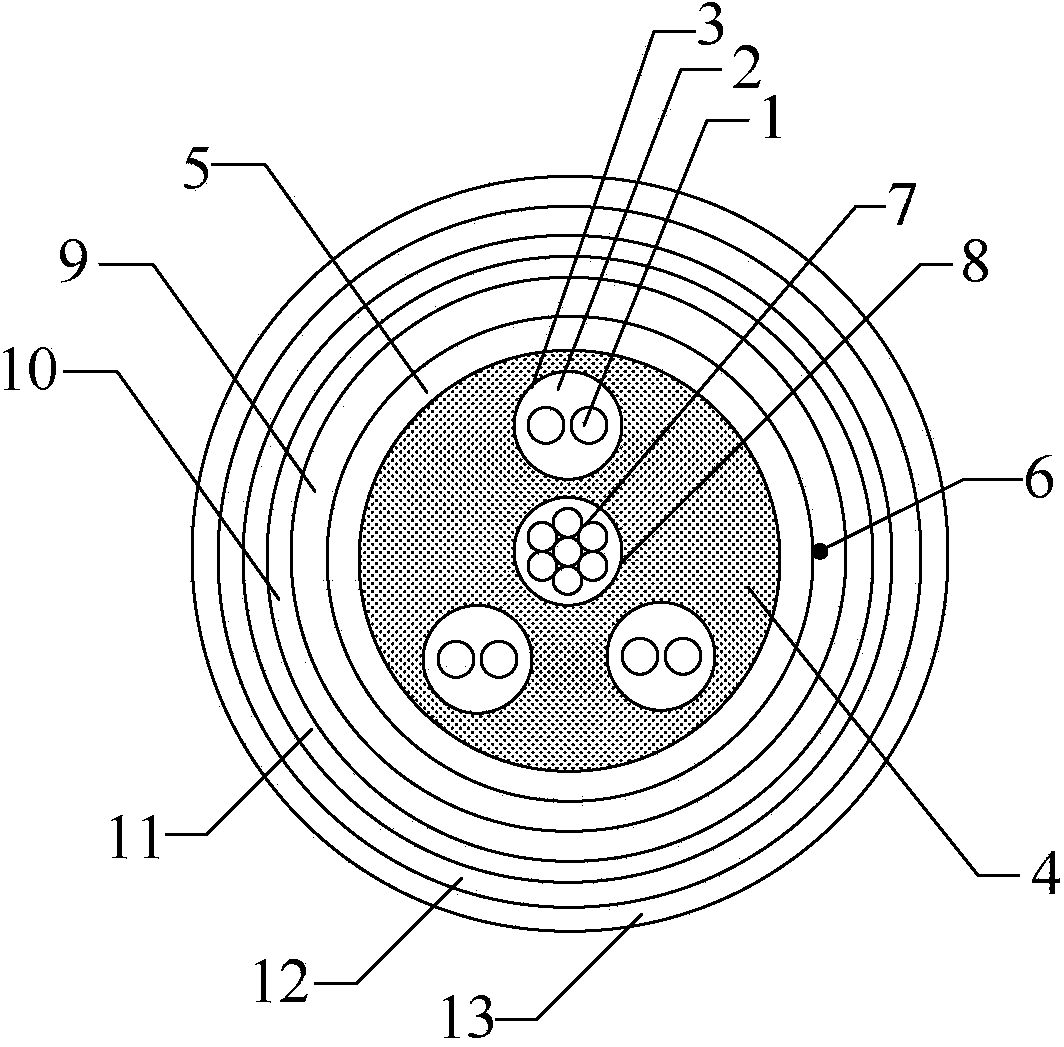

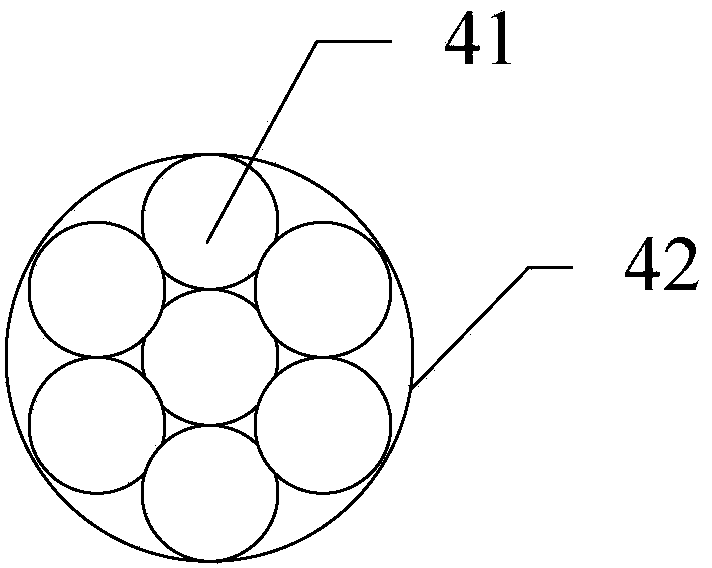

[0024] Such as figure 1 Shown is a schematic cross-sectional structure diagram of a preferred embodiment of the communication optical cable of the present invention. The communication optical cable includes an inner sheath 10 , a plurality of optical fiber units arranged in the inner sheath 10 , an armor layer 11 , a shielding layer 12 and an outer sheath 13 arranged outside the inner sheath 10 sequentially from inside to outside. The optical fiber unit includes a loose tube 3 and a plurality of optical fibers 1 arranged in the loose tube 3 . Preferably, fiber paste is filled between the optical fibers 1 in the loose tube 3 . The material of the inner sheath 10 and the outer sheath 13 is thermoplastic polyester elastomer (Thermoplastic polyester elastomer, TPEE). TPEE has the advantages of cold resistance, high temperature resistance, flexibility and wear resistance. The outer sheath 13 is covered on the outer surface of the shielding layer 12 by extrusion process. The arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com