Transparent electric conduction film

A technology of transparent conductive film and conductive layer, which is applied to conductive layers on insulating carriers, electrical digital data processing, instruments, etc. Electricity increase and other issues, to achieve the effect of low power consumption, smaller impedance, and less stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

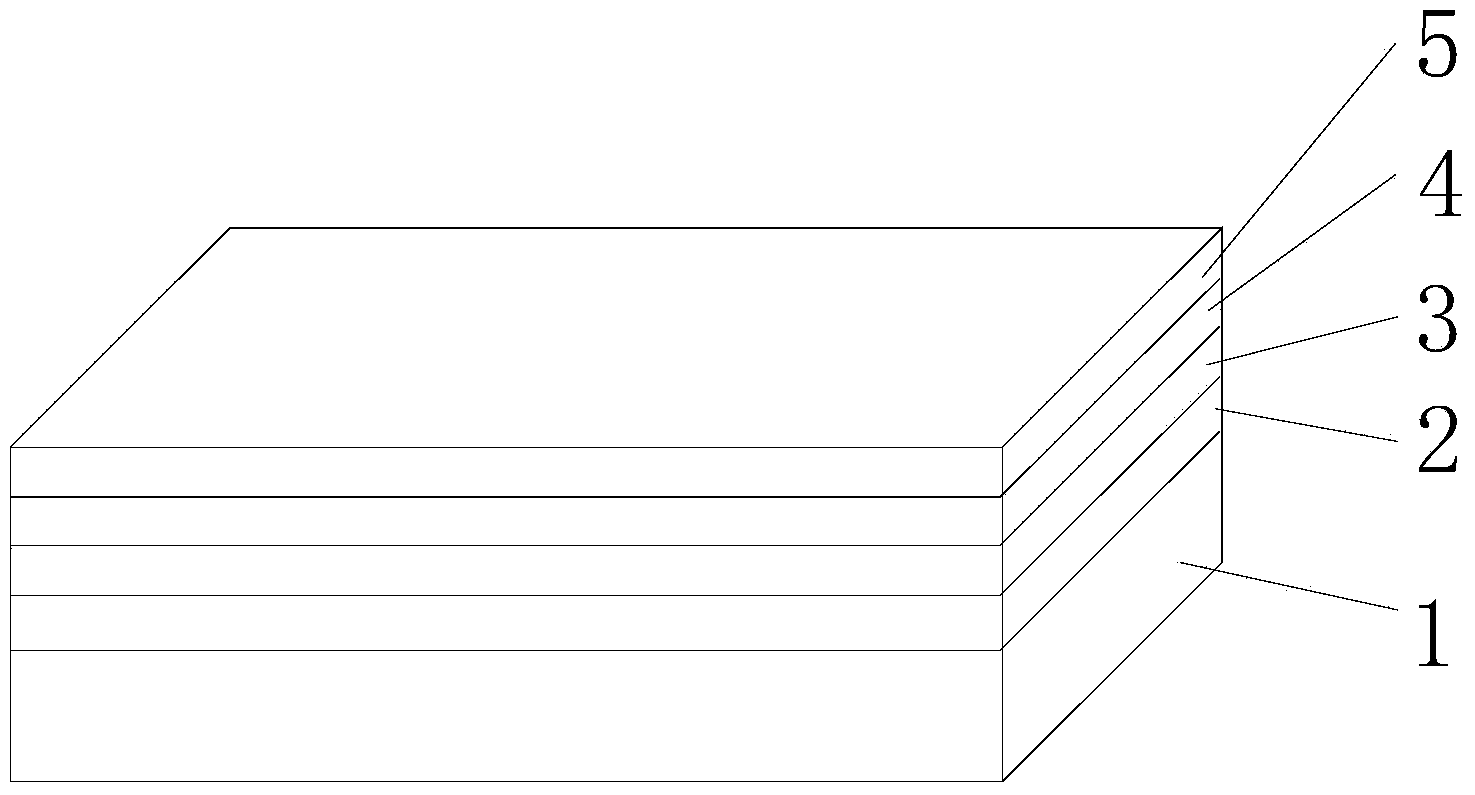

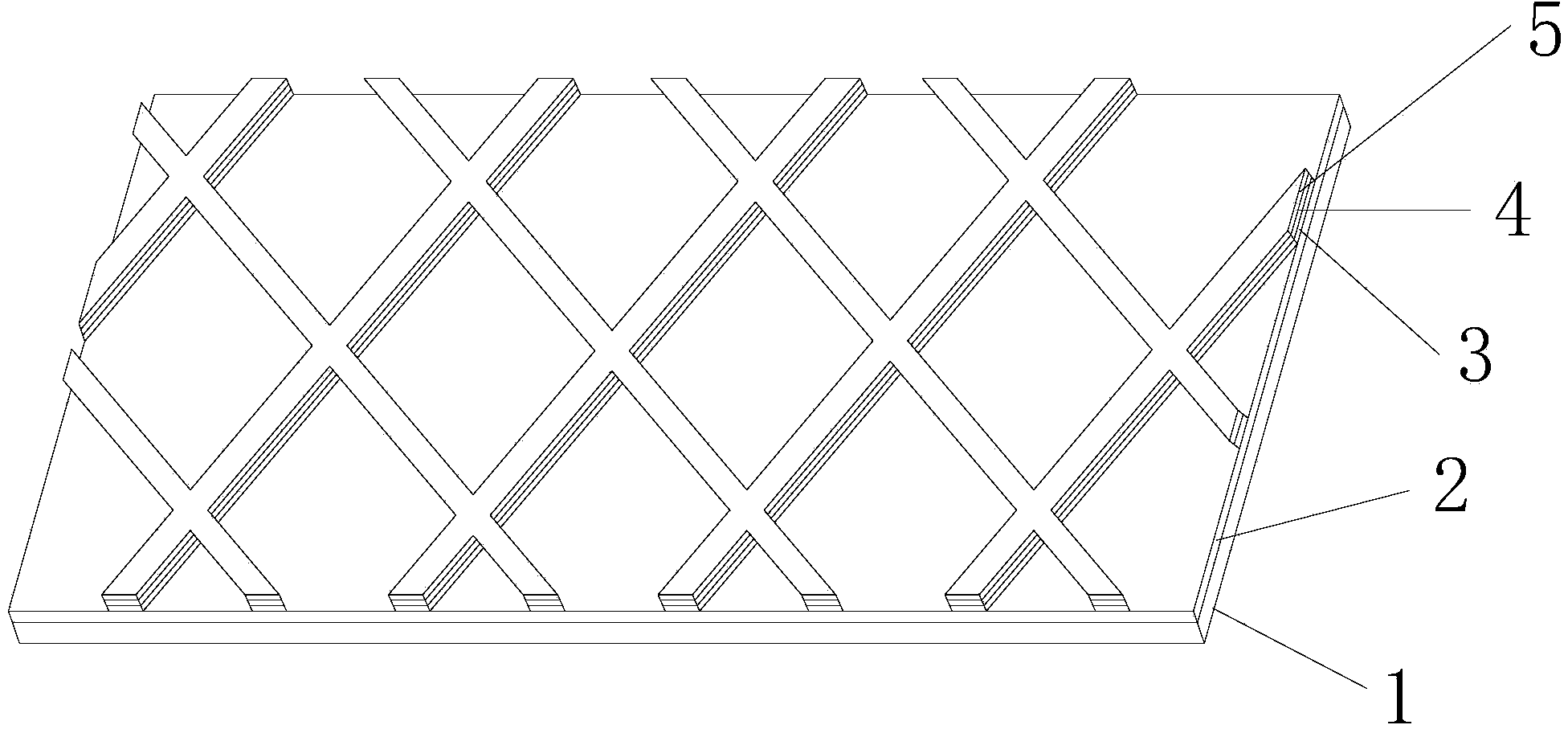

[0027] Embodiment 1 of the present invention provides a transparent conductive film, such as figure 1 As shown, the transparent conductive film involved in the present invention includes a substrate 1, a bottom layer 2, a black layer 3, a conductive layer 4, and a protective layer 5 from bottom to top. The first surface and the second surface of the base material 1 are first coated with the bottom layer 2 by vacuum sputtering or evaporation coating on the second surface of the substrate 1. The bottom layer 2 is a transparent SiO2 layer, and ink can be sprayed on the second surface to form ink pattern; then on the bottom layer 2, a black layer 3, a conductive layer 4 and a protective layer 5 are sequentially plated, wherein the black layer 3 is a mixture of chromium oxide and nickel oxide, and its thickness is 40nm-100nm, and the method of optical interference can be used to Make the black surface visible to the naked eye; the conductive layer 4 is a metal layer, preferably ...

Embodiment 2

[0029] Embodiment 2 of the present invention provides another kind of transparent conductive film, and present embodiment compares with embodiment 1, and protective layer 5 is changed into black layer 3, and black layer 3 can also play the function of preventing oxidation, like this, naked eyes also can Ability to observe from the other side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com