Novel LED constant-current drive circuit

A constant current drive and circuit technology, applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problem of poor constant current effect of high-power LED lamp, poor constant current effect of resistance-capacity step-down driver, and constant current working voltage range. narrow and other problems, to achieve the effect of good constant current effect, wide constant current operating voltage range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

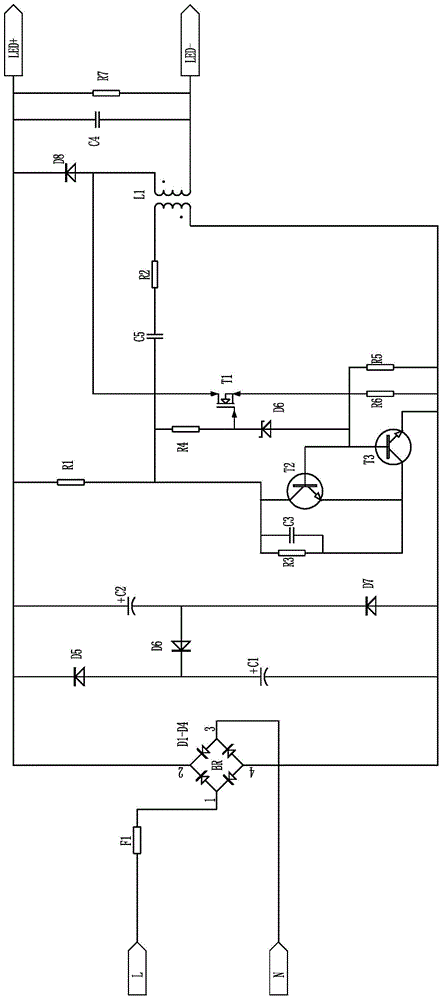

[0020] refer to figure 1 , a new type of LED constant current drive circuit provided by the present invention includes an AC input terminal, a rectification module, a filter module with a power factor correction function, a current amplification module and an output module connected in sequence. A metal oxide film fuse resistor F1 is arranged between the AC input terminal and the rectifier module. The rectification module is preferably a bridge rectification module. The filter module is composed of filter capacitors C1, C2 and one-way diodes D5 to D7, which play the role of filtering and improving the PFC value. The current amplifying module includes a current-limiting resistor R1 arranged between two poles, a first triode T2, and a second triode T3, and the first triode T2 and the second triode T3 are commonly used NPN transistors (PNP transistors can also be used), the output terminals of the current-limiting resistor R1, the first transistor T2, and the second transistor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com