High velocity mist evaporation

An evaporation system and speed technology, applied in industrial evaporators and snowmaking machines, air conditioning, seawater desalination fields, to achieve the effect of improving fan efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] For convenience, the invention will be described hereinafter with specific reference to air conditioners, although the invention is equally applicable to industrial evaporation for seawater desalination, pharmaceuticals etc. and snowmaking machines, it should be understood that the invention is not limited thereto.

[0067] Although the invention is particularly applicable to air conditioning, and this description is focused on that application, the same invention can also be used as an evaporation front end for desalination or sewage treatment systems / processes, and in snowmaking machines, without the need for pumps to feed the nozzles. pressure.

[0068] First it is worth giving some general background on the concepts behind the invention.

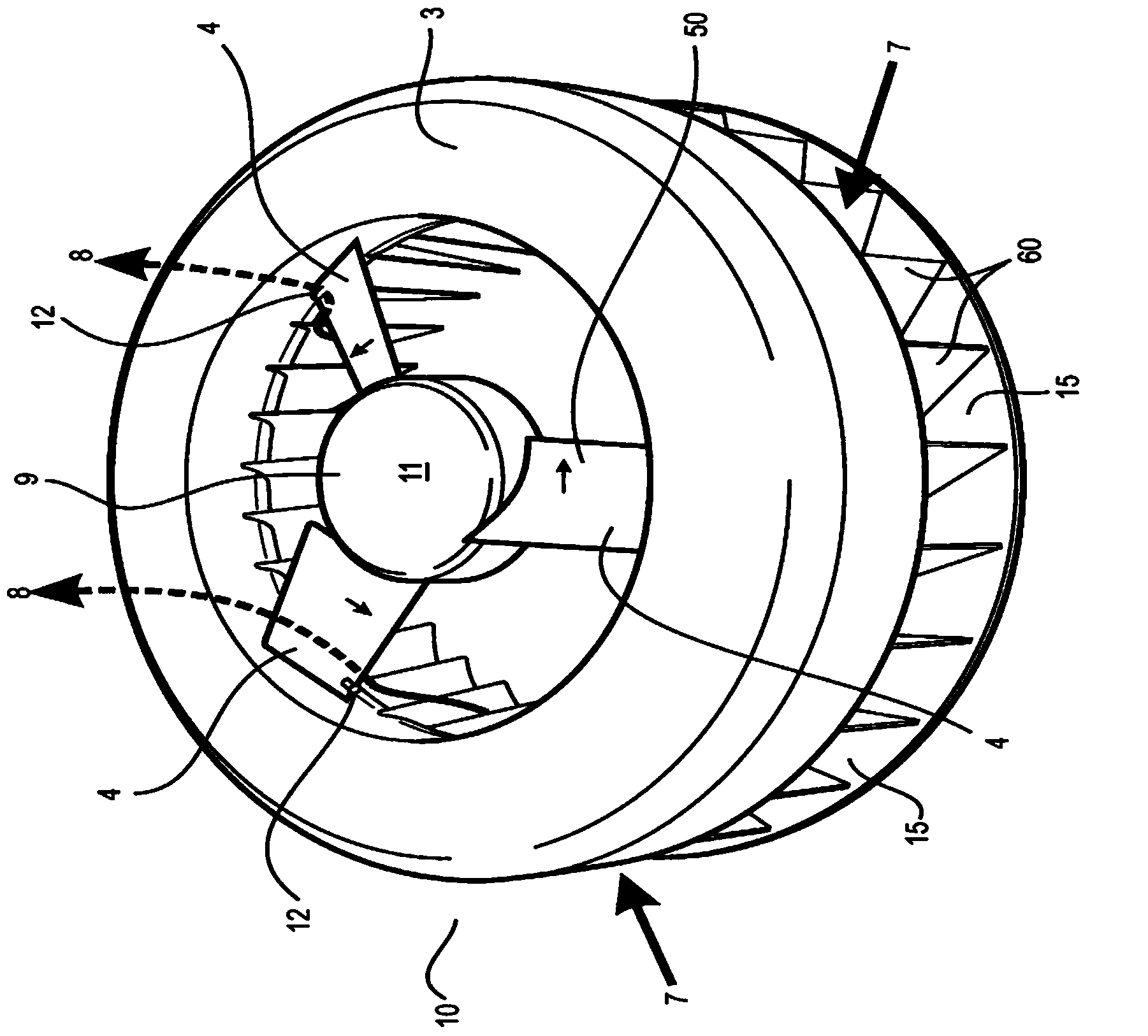

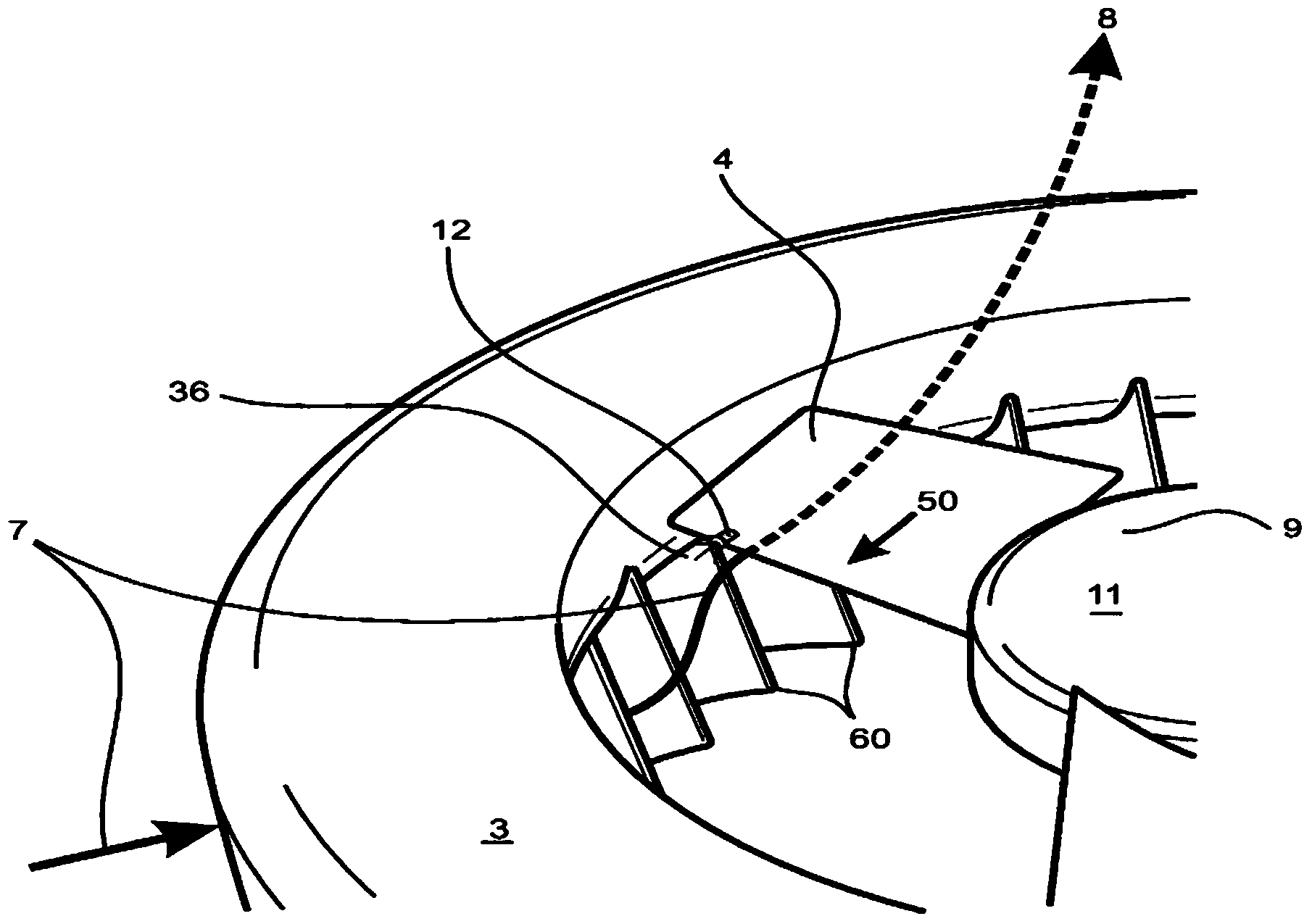

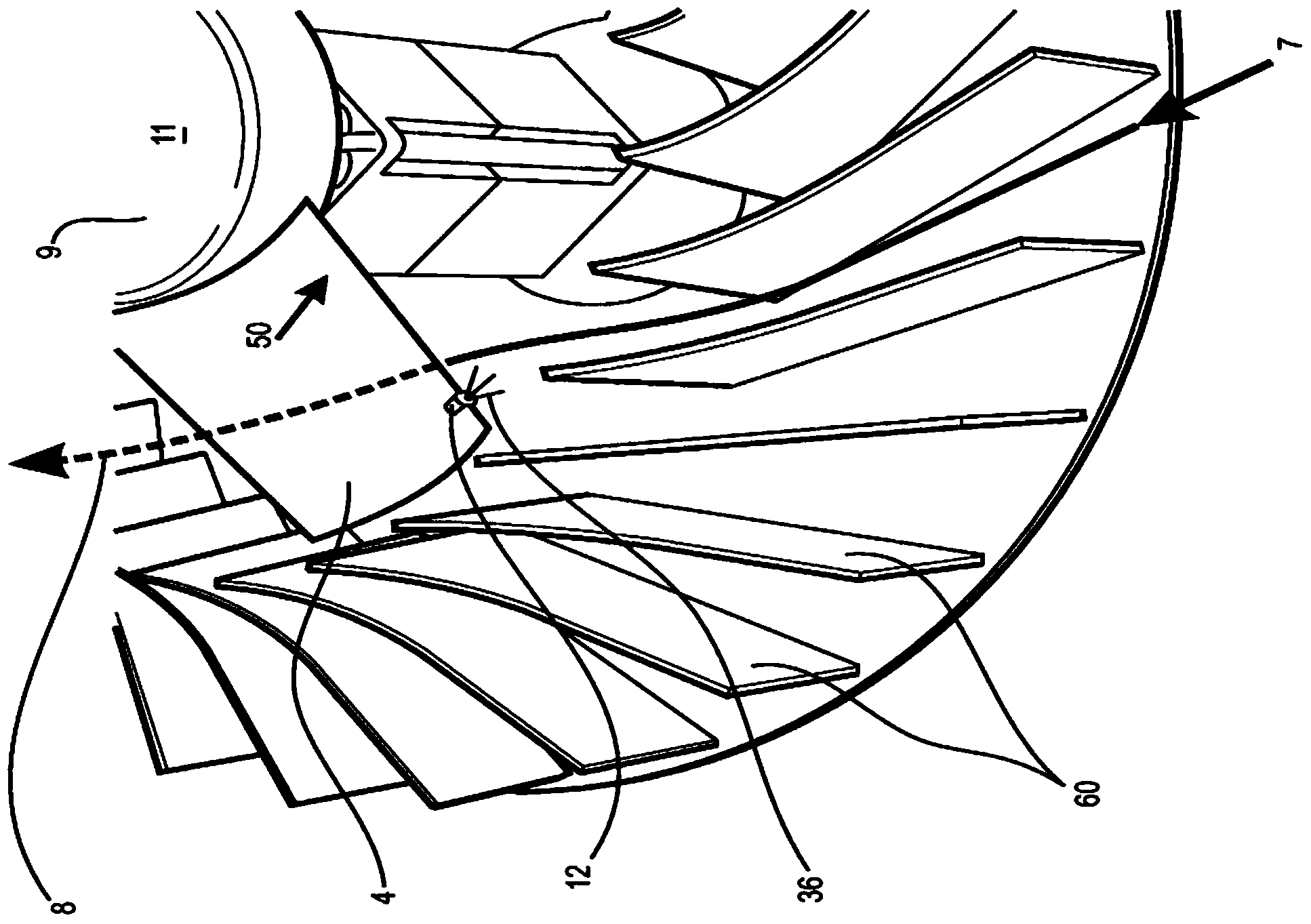

[0069] A vortex disk is a highly efficient mechanical device that is essentially a wheel. Rotating the atomizing disc requires less energy than having to use a pump to pressurize the reverse osmosis (RO) components in a tradition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com