Preparation method of red bean snack food

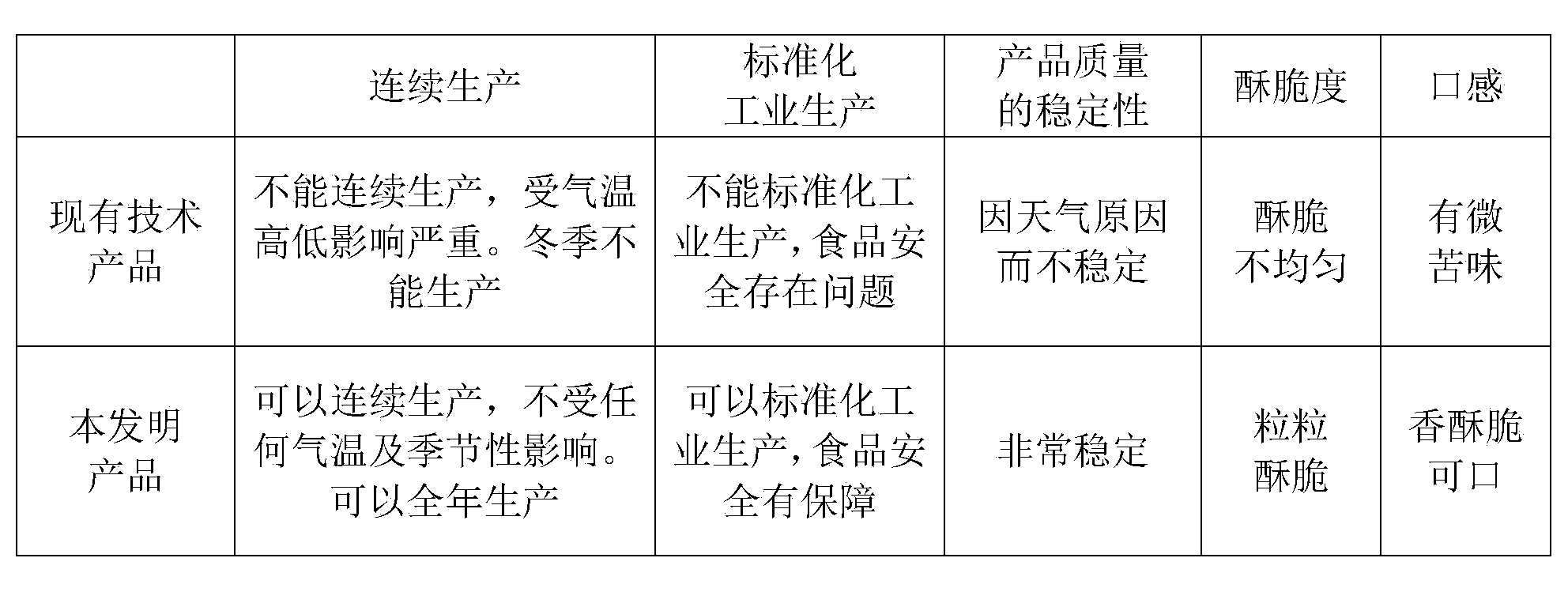

A production method and technology for snack food, applied in the field of food processing, can solve the problems of high production cost, waste of social resources, insufficient crispness, etc., and achieve the effects of solving the problem of crispness, ensuring stability and high nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Choose red beans with full granules, uniform size, and natural bright red as raw materials, put them into a tank, add 40°C water three times the weight of red beans, after sealing, keep the water temperature at 40°C for 7 hours under anaerobic conditions, and let go of the tank Then add 10°C water that is three times the weight of the raw red beans, seal it, keep the water temperature at 10°C, and keep it under anaerobic conditions for 12 hours, then take out the red beans, wash them with tap water, drain the water, and then use an air dryer Air-dry for 3 minutes, with no water droplets on the surface of the red beans as the standard. The air-dried red beans are sent to the extruder for two-stage expansion with variable temperature. The first-stage puffing temperature is controlled at 180°C and puffed for 7 minutes; the second-stage puffing temperature is controlled at 150°C and puffed for 6 minutes. Finally, send the puffed red beans to the blender while they are hot, ...

Embodiment 2

[0025] Choose red beans with full particles, uniform size, and natural bright red as raw materials, put them into a tank, add 35°C water that is 4 times the weight of red beans, after sealing, keep the water temperature at 35°C for 9 hours under anaerobic conditions, and let go of the tank Then add water at 25°C that is 4 times the weight of the raw red beans, seal it, keep the water temperature at 25°C, and keep it under anaerobic conditions for 10 hours, then take out the red beans, wash them with tap water, drain the water, and then use an air dryer Air dry for 1 minute. The air-dried red beans are sent to the extruder for two-stage expansion with variable temperature. The first-stage puffing temperature is controlled at 190°C and puffed for 4 minutes; the second-stage puffing temperature is controlled at 160°C and puffed for 3 minutes. Finally, send the puffed red beans to the blender while they are hot, add 2% salt according to the weight of the puffed red beans, stir eve...

Embodiment 3

[0027] Choose red beans with full granules, uniform size, and natural bright red as raw materials, put them into a tank, add 38°C water of 3 times the weight of red beans, after sealing, keep the water temperature at 38°C for 8 hours under anaerobic conditions, and let go of the tank Then add water at 20°C that is 4 times the weight of the raw red beans, seal it, keep the water temperature at 20°C, and keep it under anaerobic conditions for 11 hours, then take out the red beans, wash them with tap water, drain the water, and then use an air dryer Air dry for 2 minutes. The air-dried red beans are sent to the extruder for two-stage expansion with variable temperature. The first-stage puffing temperature is controlled at 185°C and puffed for 6 minutes; the second-stage puffing temperature is controlled at 155°C and puffed for 5 minutes. Finally, send the puffed red beans to the mixer while hot, add 3% salt, 1.5% white sugar, 0.5% chili powder, and 0.3% monosodium glutamate accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com