Nelumbo nucifern paste stuffing and preparation method thereof

A technology of stuffing and lotus root, which is applied in food preparation, baking, baked food, etc., can solve the problems of high cost, time-consuming and laborious, and high price of lotus seeds, and achieve the effects of low moisture content, reducing economic losses, and facilitating preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

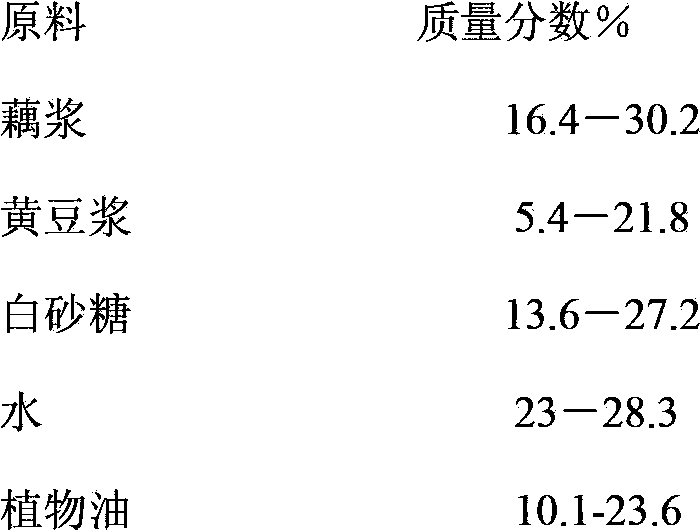

[0035] A kind of lotus root filling, it is made of the raw material of following mass fraction:

[0036]

[0037] A preparation method for lotus root filling, the steps are:

[0038] 1) Raw material pretreatment: wash the lotus root sold in the market, peel it, and cut it into sections. Commercially available soybeans are cleaned and set aside.

[0039] 2) Cooking: Add citric acid (food grade), VC (food grade), NaCl (food grade) and lotus root segments to water and cook for 1.5-3 hours. Soybeans are boiled for 12-20 minutes.

[0040] 3) Beating: Cut the lotus root into cubes and beat with a blender; peel the soybeans and beat with a blender.

[0041] Preparation: Mix and prepare lotus root milk, soybean milk, white sugar and water. Among them, the proportion of soybean milk to the total material is 5.4-21.8, the proportion of white sugar to beating is 13.6-27.2, water 23-28.3, and vegetable oil 10.1-23.6 for use.

[0042] 4) Frying: Pour vegetable oil into a pan, heat ...

Embodiment 2

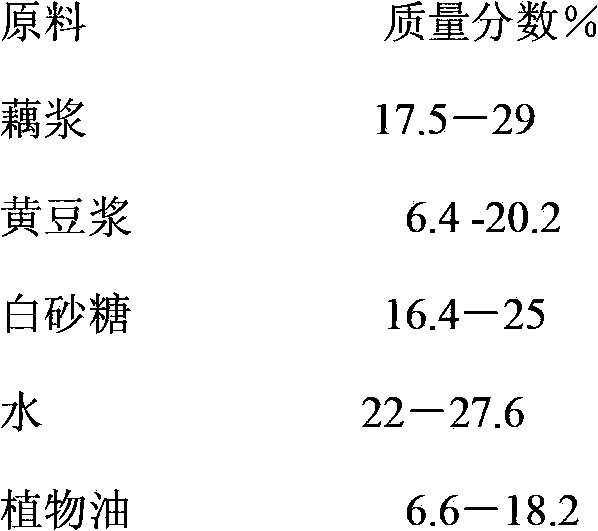

[0046] A kind of lotus root filling, it is made of the raw material of following mass fraction:

[0047]

[0048]

[0049] A preparation method for lotus root filling, the steps are:

[0050] 1) Raw material pretreatment: wash the lotus root sold in the market, peel it, and cut it into sections. Commercially available soybeans are cleaned and set aside.

[0051] 2) Cooking: Add citric acid (food grade), VC (food grade), NaCl (food grade) and lotus root segments to water and cook for 1.5-3 hours. Soak soybeans for 12-20 minutes.

[0052] 3) Beating: Cut the lotus root into cubes and beat with a blender; peel the soybeans and beat with a blender.

[0053] Preparation: Mix and prepare lotus root milk, soybean milk, white sugar and water. Among them, the proportion of soybean milk to the total material is 5.4-21.8, the proportion of white sugar to beating is 13.6-27.2, water 23-28.3, and vegetable oil 10.1-23.6 for use.

[0054] 4) Frying: Pour vegetable oil into a pan,...

Embodiment 3

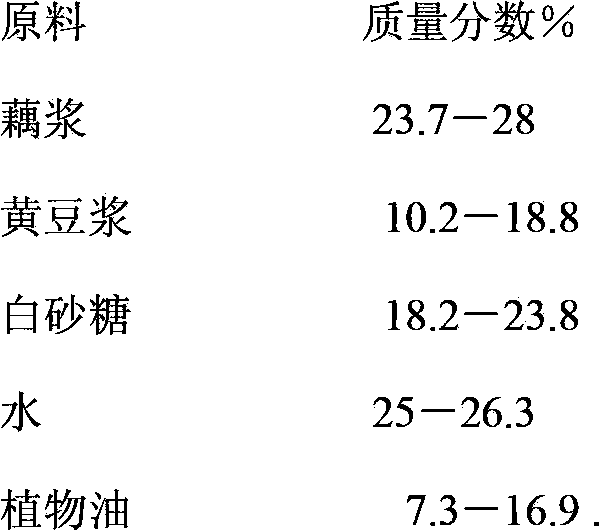

[0057] A kind of lotus root filling, it is made of the raw material of following mass fraction:

[0058]

[0059] A preparation method for lotus root filling, the steps are:

[0060] 1) Raw material pretreatment: wash the lotus root sold in the market, peel it, and cut it into sections. Commercially available soybeans are cleaned and set aside.

[0061]2) Cooking: Add citric acid (food grade), VC (food grade), NaCl (food grade) and lotus root segments to water and cook for 1.5-3 hours. Soak soybeans for 12-20 minutes.

[0062] 3) Beating: Cut the lotus root into cubes and beat with a blender; peel the soybeans and beat with a blender.

[0063] Preparation: Mix and prepare lotus root milk, soybean milk, white sugar and water. Among them, the proportion of soybean milk to the total material is 5.4-21.8, the proportion of white sugar to beating is 13.6-27.2, water 23-28.3, and vegetable oil 10.1-23.6 for use.

[0064] 5) Frying: Pour vegetable oil into a pan, heat it at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com