Mold structure for semi-hollow profile with high slenderness ratio and manufacturing method of mold structure

A mold manufacturing and semi-hollow technology, which is applied in the field of processing molds and processing technology of aluminum alloy profiles for green buildings, can solve the problems of short mold use time and low mold processing efficiency, achieve high production efficiency, reduce technical difficulty and production Cost, the effect of increasing the surface hardness value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

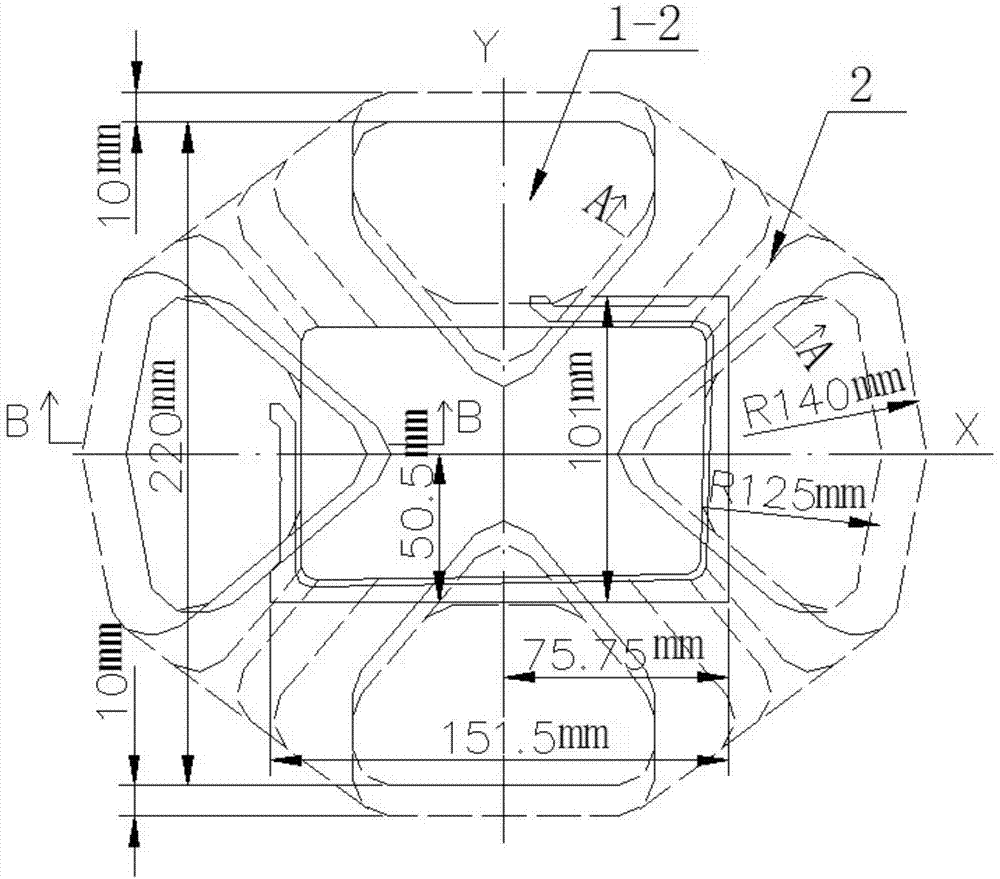

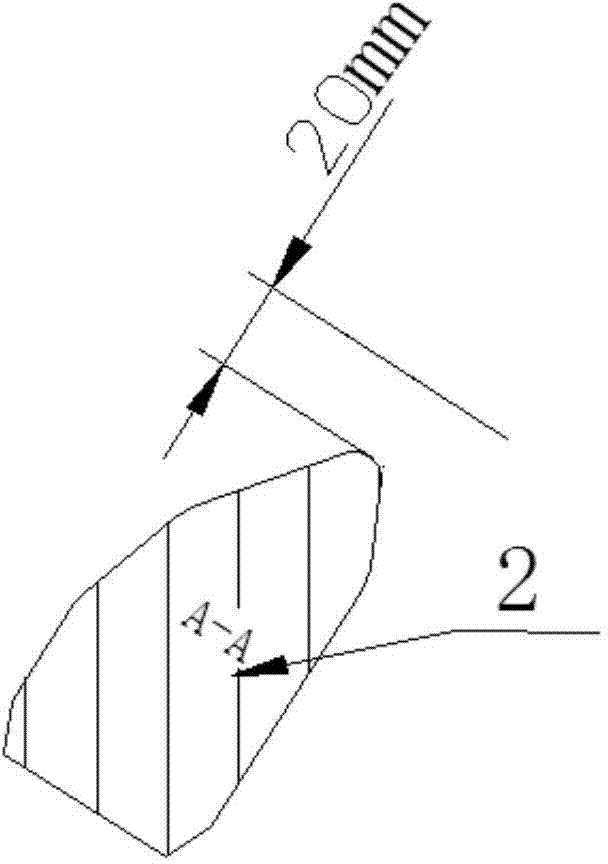

[0034] Such as figure 2 , image 3 , Figure 4 and Figure 5 A mold structure with a large tongue ratio and a semi-hollow profile is shown. The mold adopts a shielded mold structure. The shielded mold includes an upper mold 1 and a lower mold 2. The upper mold 1 is provided with four evenly distributed shunts. Hole 1-2, die hole 2-2 and welding chamber 2-3 are provided on the lower die 2, and cantilever 2-1 is provided at the die hole 2-2; the mold core 1-1 of the upper die 1 partially covers the lower die The position of the cantilever 2-1 at the die hole 2-2 of 2 prevents the cantilever 2-1 of the mold from directly bearing the force of the deformed metal; the mold core 1-1 of the upper die 1 is shortened by 0.8-1.0 mm, and the cantilever There is a gap of 0.8-1.0mm between the top of part 2-1 and the bottom of part 1-1 of the mold core, which is used to eliminate the pressure on the cantilever due to the elastic deformation or extrusion of the center. This mold can effe...

specific Embodiment 2

[0055] The characteristics of this embodiment are: in the manufacturing method of the mold, the mold is quenched at a high temperature of 1035° C., and other features are the same as those of the specific embodiment 1.

specific Embodiment 3

[0056] The characteristics of this embodiment are: in the manufacturing method of the mold, the mold is quenched at a high temperature of 1035° C., and other features are the same as those of the specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com