Environment-friendly fragrant aluminum-wood composite board as well as preparation method thereof

A composite board and fragrance technology, applied in the field of aluminum-wood composite board, can solve problems such as unsightly appearance and uneven surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

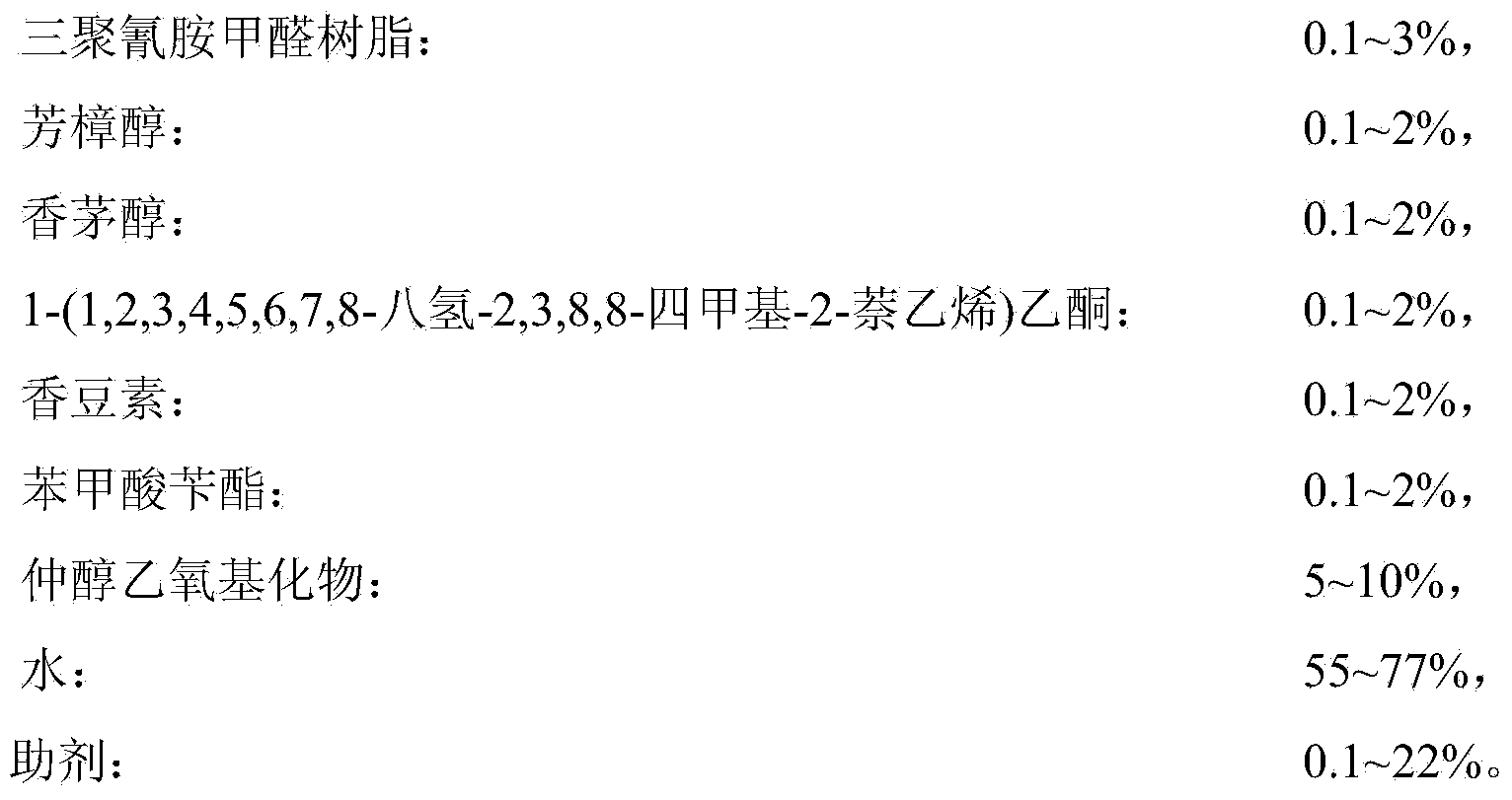

[0264] Spices include the following components in mass percentages:

[0265]

[0266] Diluents include butyl ether (30%), cyclohexanone (30%), n-butanol (30%), isophorone (10%).

[0267] The preparation method of modified polyester paint comprises the following steps:

[0268] Add polyester paint with a mass percentage of 75% and spices with a mass percentage of 20% and stir together, add a diluent with a mass percentage of 5% while stirring, stir for 3 hours, and filter to obtain a modified Polyester paint.

[0269] First, the area is 2.97m 2 The aluminum skin passes through the degreasing tank with a length of 12m at a speed of 20m / min. The degreasing tank is preset with a degreasing agent, and the ratio of the degreasing agent to water is 0.04:1. The ratio of degreasing agent to degreasing auxiliary agent is 2:1, and the length is 7m in the clear water tank, and then enters the 6m long oven for the first drying at a temperature of 85°C. After drying, it is coated on the...

Embodiment 2

[0275] Spices include the following components in mass percentages:

[0276]

[0277] Diluents include butyl ether (30%), cyclohexanone (30%), n-butanol (30%), isophorone (10%).

[0278] The preparation method of modified polyester paint comprises the following steps:

[0279] Add polyester paint with a mass percentage of 80% and spices with a mass percentage of 18% and stir together, add a diluent with a mass percentage of 2% while stirring, stir for 4 hours, and filter to obtain a modified Polyester paint.

[0280] First, the area is 2.97m 2 The aluminum skin passes through the degreasing tank with a length of 13m at a speed of 20m / min. The degreasing tank is preset with a degreasing agent, and the ratio of the degreasing agent to water is 0.07:1, wherein: the degreasing agent includes a degreasing agent and a degreasing auxiliary agent, The ratio of degreasing agent to degreasing auxiliary agent is 3:1, and the length is 7.5m in the clear water tank, and then enters t...

Embodiment 3

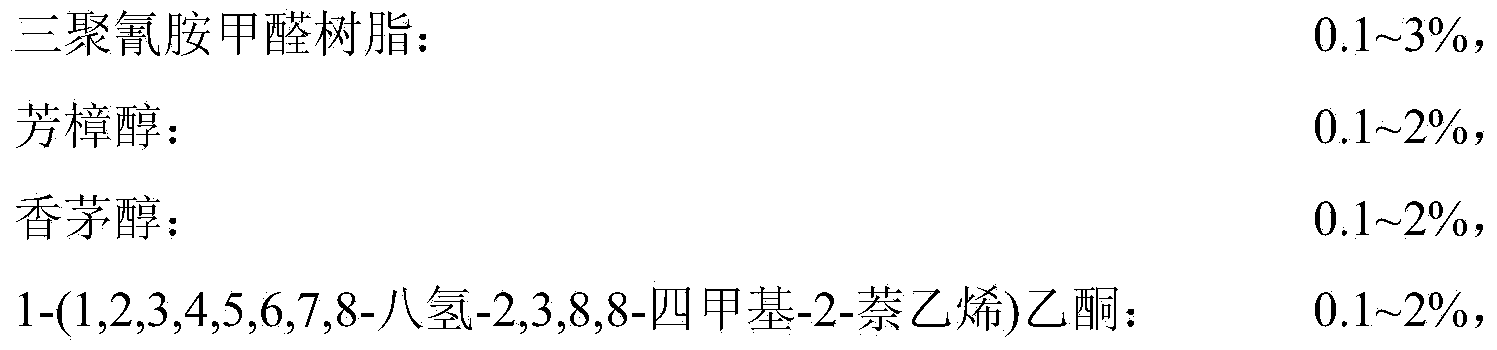

[0285] Spices include the following components in mass percentages:

[0286]

[0287] Diluents include butyl ether (30%), cyclohexanone (30%), n-butanol (30%), isophorone (10%).

[0288] The preparation method of modified polyester paint comprises the following steps:

[0289] Add polyester paint with a mass percentage of 93% and spices with a mass percentage of 5% and stir together, add a diluent with a mass percentage of 2% while stirring, stir for 5h, and filter to obtain a modified Polyester paint.

[0290] First, the area is 2.97m 2 The aluminum skin passes through the degreasing tank with a length of 14m at a speed of 20m / min. The degreasing tank is preset with a degreasing agent, and the ratio of the degreasing agent to water is 0.1:1. The ratio of degreasing agent to degreasing auxiliary agent is 4:1, and the length is 8m in the clear water tank, and then enters the 6m long oven for the first drying at a temperature of 95°C, and coats the aluminum skin with a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com