Foaming type vehicle-bottom chip-resistant paint

An anti-stone impact and foaming technology, applied in the coating and other directions, can solve the problem of increasing the weight of the car body, and achieve the effect of reducing the weight of the car body and reducing the anti-stone impact coating of the foamed bottom of the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

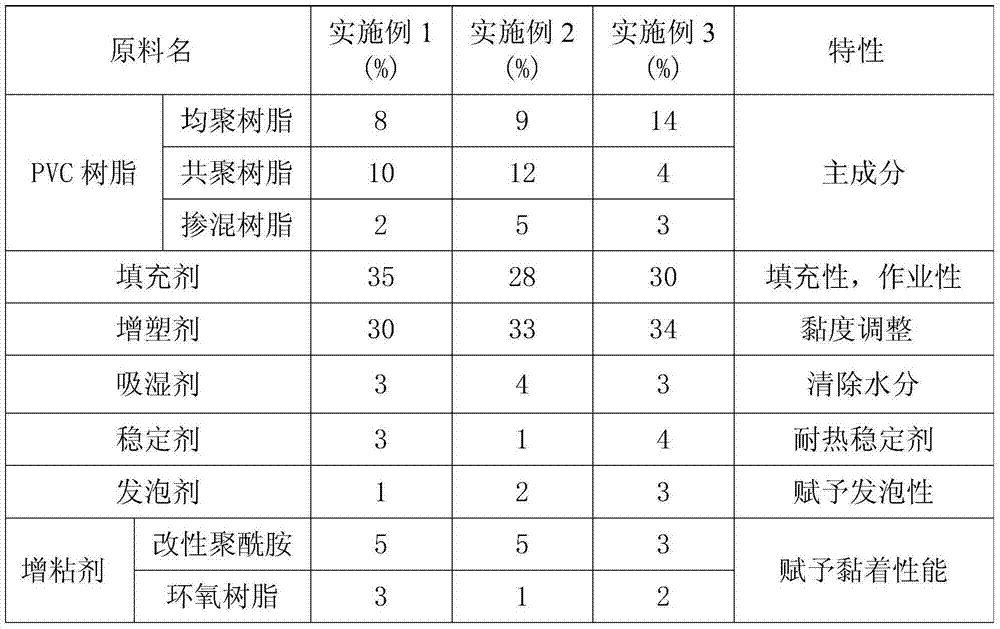

Embodiment 1-3

[0017]

[0018] Table 1 is the basic performance of the embodiment and the comparative example and the required weight of a single vehicle body. The comparative example is the composition table of the foamed anti-stone chip paint for the bottom of the car manufactured by the usual method.

[0019] experimental project

[0020] According to the results in Table 1, under the premise of meeting the same performance requirements, the amount of foamed car bottom anti-stone chip coating can be reduced by about 1.5Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com