Method for refining cast titanium alloy crystalline grains

A technology for casting titanium alloys and grain refinement, which is applied in the field of titanium alloy grain refinement, can solve the problems of high production cost, deterioration of mechanical properties of titanium alloy components, low material utilization rate, etc., and achieve high material utilization rate and casting The effect of quality control and tissue uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

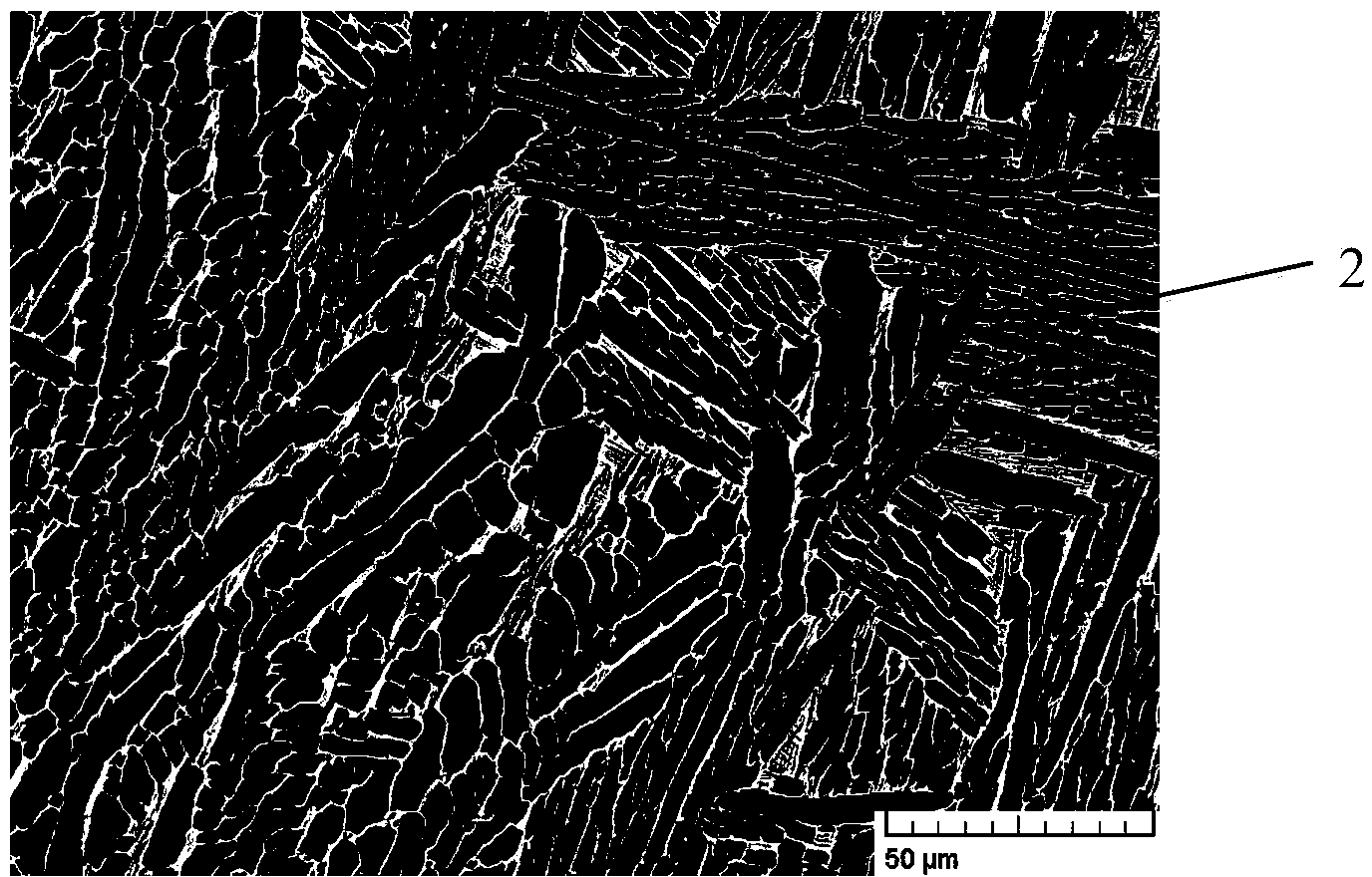

[0030] This embodiment is a method for grain refinement of titanium alloy.

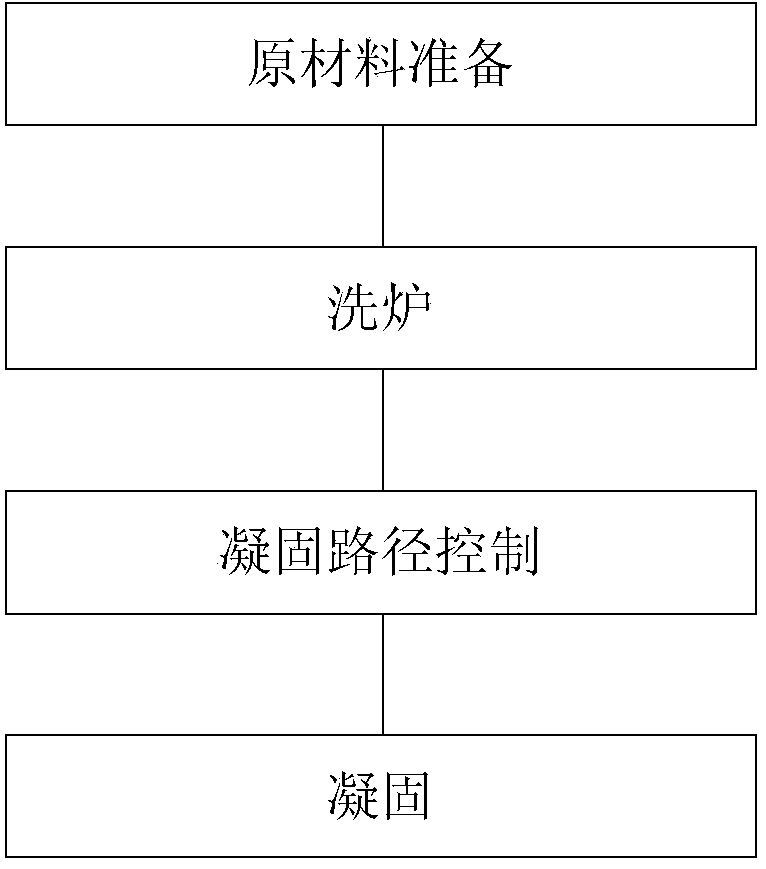

[0031] The concrete process of this embodiment is:

[0032] Step 1, raw material preparation. The raw material preparation includes the preparation of the titanium alloy test rod and the preparation of the corundum crucible.

[0033] Preparation of the titanium alloy test rod: the alloy test rod of Φ18×20mm is cut by wire cutting, and the titanium alloy is ZTC4. The obtained ZTC4 alloy test rod was ground and ultrasonically cleaned.

[0034] Preparation of corundum crucible: The surface layer material was made of yttrium oxide powder and zirconium acetate sol at a weight ratio of 3.5:1, evenly coated on the inner surface of the corundum crucible, dried naturally for 48 hours, placed in a heat treatment furnace, and sintered at 950°C for two Hour. After sintering, cool to room temperature with the furnace. Tighten the sintered corundum crucible with Mo wire to prevent the crucible from cracking du...

Embodiment 2

[0040] This embodiment is a method for grain refinement of titanium alloy.

[0041] The concrete process of this embodiment is:

[0042] Step 1, raw material preparation. The raw material preparation includes the preparation of the titanium alloy test rod and the preparation of the corundum crucible.

[0043] Preparation of the titanium alloy test rod: the alloy test rod of Φ18×20mm is cut by wire cutting, and the titanium alloy is ZTA15. The obtained ZTA15 alloy test rod was ground and ultrasonically cleaned.

[0044] Preparation of corundum crucible: Prepare the surface layer material with yttrium oxide powder and zirconium acetate sol at a weight ratio of 4.2:1, evenly coat the inner surface of the corundum crucible, dry it naturally for 48 hours, place it in a heat treatment furnace, and sinter two layers at 950°C. Hour. After sintering, cool to room temperature with the furnace. Tighten the sintered corundum crucible with Mo wire to prevent the crucible from cracking...

Embodiment 3

[0050] This embodiment is a method for grain refinement of titanium alloy.

[0051] The concrete process of this embodiment is:

[0052] Step 1, raw material preparation. The raw material preparation includes the preparation of the titanium alloy test rod and the preparation of the corundum crucible.

[0053] Preparation of the titanium alloy test rod: the alloy test rod of Φ18×20mm is cut by wire cutting, and the titanium alloy is ZTA7. The obtained ZTA7 alloy test rod was ground and ultrasonically cleaned.

[0054] Preparation of corundum crucible: Yttrium oxide powder and zirconium acetate sol were prepared as a surface layer material at a weight ratio of 4.5:1, evenly coated on the inner surface of the corundum crucible, dried naturally for 48 hours, placed in a heat treatment furnace, and sintered at 950°C for two Hour. After sintering, cool to room temperature with the furnace. Tighten the sintered corundum crucible with Mo wire to prevent the crucible from cracking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com