Bismuth brass alloy drawn tube containing trace rare earth and manufacturing method thereof

A technology for drawing tubes and bismuth brass, which is applied in the field of bismuth brass alloy drawing tubes and its manufacture, can solve the problems of insufficient dimensional accuracy, restraint, and insufficient hardness, and achieve low mechanical properties, low cost, and low mechanical properties. The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

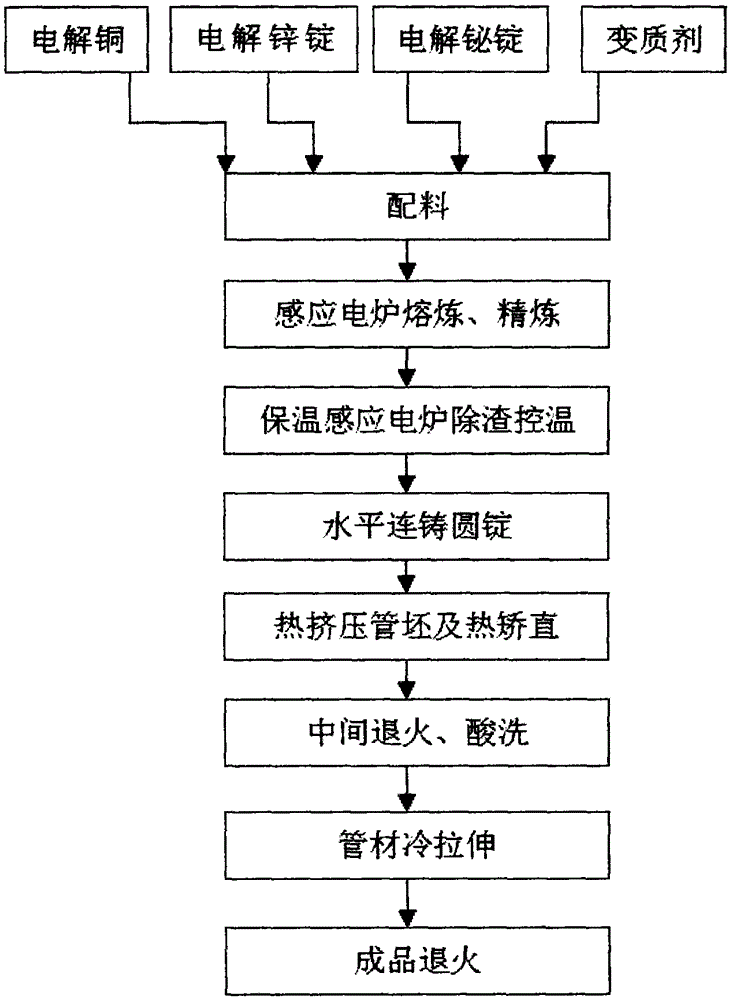

[0015] The present invention is described in further detail below in conjunction with accompanying drawing:

[0016] A bismuth brass drawn tube containing a trace amount of rare earth, its alloy composition is as follows: Cu: 58.0%-61.0%, Bi: 0.8%-1.5%, impurity elements: Pb≤0.03% , Fe≤0.15%, Sn≤0.15%, Al≤0.10%, Ni≤0.10%, Mn≤0.02%, Si≤0.02%, Cd≤0.003%, the balance is Zn; the amount of rare earth modifier: 0.05% ~0.15%, the rare earth modifier refers to a mixture of metals such as cerium and lanthanum.

[0017] Such as figure 1 As shown, the manufacturing method of the bismuth brass drawn tube containing a trace amount of rare earth comprises the following steps:

[0018] Ingredients: 2500kg / furnace according to the alloy ratio;

[0019] Melting: Put copper and part of zinc into the melting furnace in batches to melt and stir; after the above-mentioned copper and zinc are all melted, add the remaining zinc and bismuth; after all are melted, stir the alloy liquid for 5-10 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com