Lime nail composite frame prestressed anchor tube structure and construction method for reinforcing weak slope

A technology of composite frame and construction method, which is applied in foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of low shear strength, high engineering cost, and high engineering cost, achieve increased shear strength, ensure grouting Quality and the effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

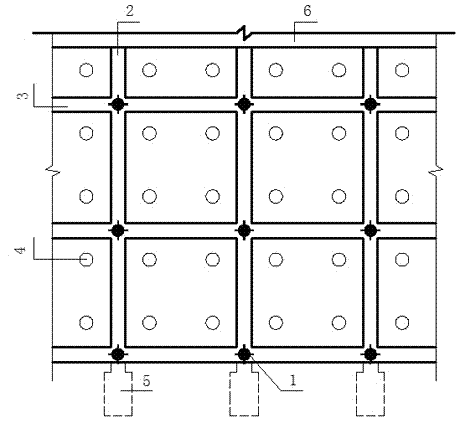

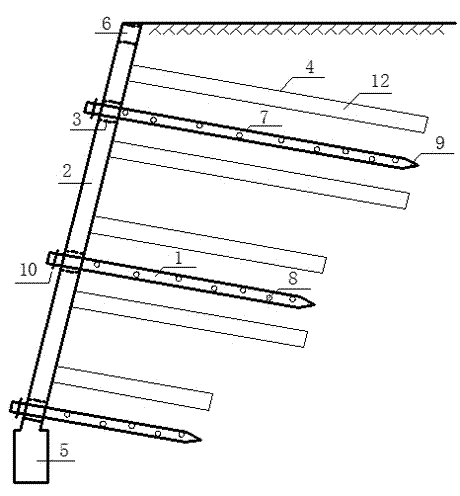

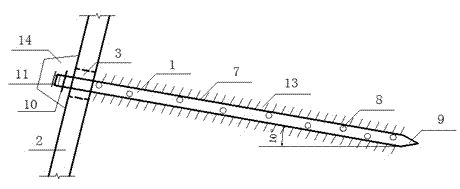

[0015] The present invention is the prestressed anchor tube structure and the construction method of the lime nail composite frame of strengthening weak soil slope, such as figure 1 , figure 2 ,

[0016] image 3 As shown, the lime nail composite frame prestressed anchor tube structure for strengthening soft soil slopes is composed of lime nails 4, columns 2, beams 3 and prestressed anchor tubes 1, and the prestressed anchor tubes 1 are located in the center of the square formed by lime nails 4; the upright columns 2. The beam 3 and the prestressed anchor pipe 1 form a spatial structure system. The prestressed anchor pipe 1 passes through the intersection of the column 2 and the beam 3; and a drill bit 9; the fast-hardening high-strength cement anchoring agent 13 is injected into the prestressed anchor pipe 1, and the steel backing plate 10 anchors the end of the prestressed anchor pipe 1 at the intersection of the column 2 and the beam 3, and the frame is subjected to T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com