Praseodymium-Ferrum-Boron permanent magnet and preparation method thereof

A technology of permanent magnets and praseodymium-iron-boron, applied in the field of praseodymium-iron-boron permanent magnets and its preparation, can solve problems such as poor vacuum sealing, increased corner size, and poor dimensional accuracy, and achieve excellent magnetic properties, low manufacturing cost, Effect of good magnetic field stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

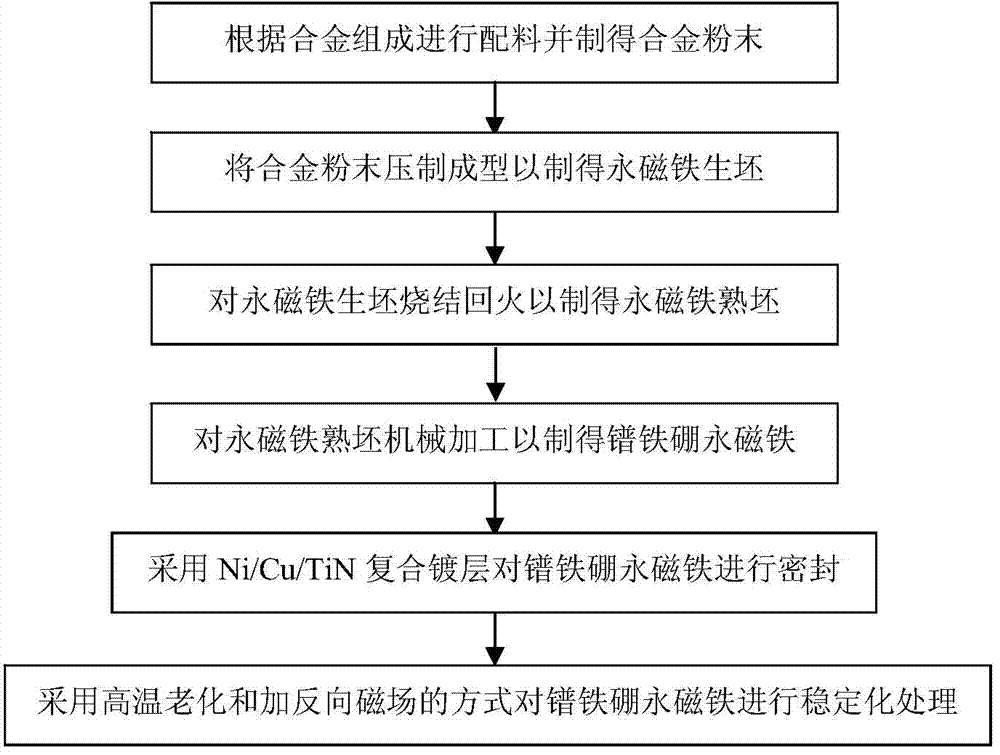

[0048] The preparation method of praseodymium iron boron permanent magnet of the present invention is as figure 1 As shown, the method includes the following steps:

[0049] (1) Dosing according to the alloy composition and preparing alloy powder

[0050] The alloy composition is designed according to the principles of high Br and high Hci, while considering factors such as squareness, Pr loss, oxygen content, temperature coefficient, etc., as follows (the content of each element involved in the following is a mass percentage):

[0051] i. In order to maintain the main phase magnetic structure, while considering the easy oxidation of metal Pr, the content of metal Pr is controlled at 30.3%, and considering the actual loss in the oxidation and smelting process, the content of metal Pr is appropriately increased to no more than 31.8%;

[0052] ii. In order to increase the intrinsic coercive force of the permanent magnet, while considering factors such as cost and low-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com