White light led packaging process

A technology of LED packaging and white light, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that affect LED luminous efficiency and cannot improve color uniformity, achieve improved LED color uniformity, good spatial color uniformity, and overcome The effect of settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

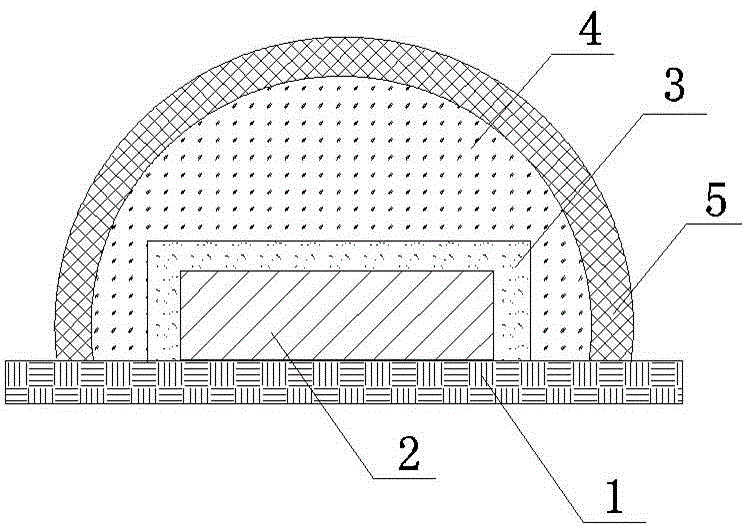

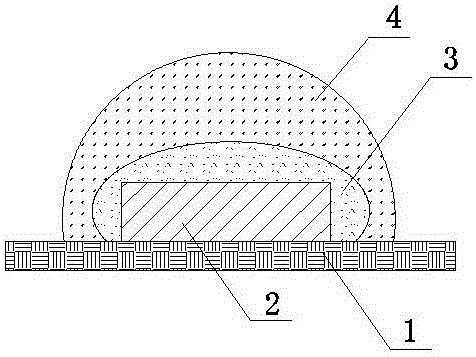

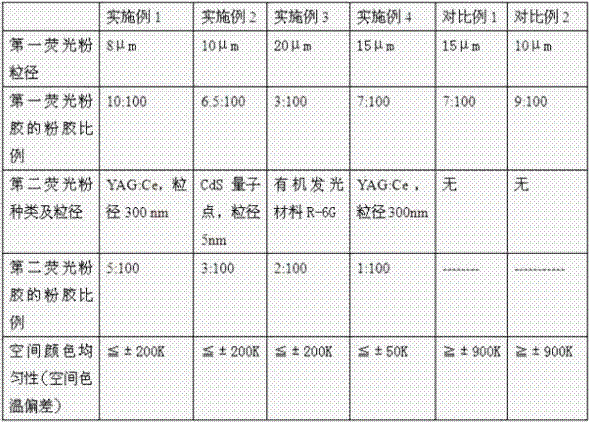

[0025] A white light LED packaging process, comprising the following steps:

[0026] (a) Die-bonding and wire-bonding the blue LED chip 2 on the substrate 1;

[0027] (b) Preparation of the first fluorescent powder glue: Select the commercial yellow phosphor YAG-04 with a particle size of 8 μm and mix it in Shin-Etsu 5547 silica gel, the ratio of phosphor to glue is 10:100, stir and degas to obtain the first phosphor glue;

[0028] (c) Forming the first phosphor layer 3 on the LED wafer 2 with the first phosphor glue by a conformal coating method;

[0029] (d) putting the LED chip 2 coated with the first phosphor layer 3 into an oven for solidification, and taking it out after cooling to room temperature;

[0030] (e) Prepare the second phosphor glue: mix YAG:Ce inorganic phosphor with a particle size of 300nm in Dow Corning 6650 silica gel, control the ratio of YAG:Ce phosphor to Dow Corning 6650 silica gel at 5:100, stir and degas , to obtain the second phosphor glue;

...

Embodiment 2

[0035] A white light LED packaging process, comprising the following steps:

[0036] (a) Die-bonding and wire-bonding the blue LED chip 2 on the substrate 1;

[0037](b) Preparation of the first phosphor glue: mix commercial yellow phosphor YAG-04 with a particle size of 10 μm and orange phosphor O5742 (the ratio of yellow phosphor YAG-04 to orange phosphor O5742 is 7:3) in Shin-Etsu 5547 In silica gel, the ratio of phosphor to glue is 6.5:100, stir and degas to obtain the first phosphor glue;

[0038] (c) Forming the first phosphor layer 3 on the LED wafer 2 with the first phosphor glue by a dispensing coating method;

[0039] (d) putting the LED chip 2 coated with the first phosphor layer 3 into an oven for solidification, and taking it out after cooling to room temperature;

[0040] (e) Prepare the second phosphor glue: mix CdS quantum dots with a particle size of 5nm in Dow Corning 6650 silica gel, control the ratio of phosphor to glue at 3:100, stir and degas to obtain ...

Embodiment 3

[0045] A white light LED packaging process, comprising the following steps:

[0046] (a) Die-bonding and wire-bonding the blue LED chip on the substrate;

[0047] (b) Preparation of the first phosphor glue: Mix commercial yellow phosphor YAG-04 with a particle size of 20 μm and nitride red phosphor (the ratio of yellow phosphor YAG-04 to nitride red phosphor is 6:4) in In the epoxy glue, the ratio of phosphor to glue is 3:100, mix, stir, and degas to obtain the first phosphor glue;

[0048] (c) Forming the first phosphor layer 3 on the LED wafer 2 with the first phosphor glue by a dispensing coating method;

[0049] (d) putting the LED wafer 2 coated with the first phosphor layer 3 into an oven for curing, the baking time is 1-3 hours, the baking temperature is 100-150 degrees Celsius, and taken out after cooling to room temperature;

[0050] (e) Prepare the second fluorescent powder glue: dissolve the organic light-emitting material R-6G in the second colloid--molding glue,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com