Dental material, dental material composition, dental repair material, and cured product

A technology for dental materials and restorative materials, used in dentistry, dental preparations, dental prostheses, etc., can solve problems such as complicated synthesis, and achieve the effects of reducing secondary caries, excellent aesthetics, and ensuring transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

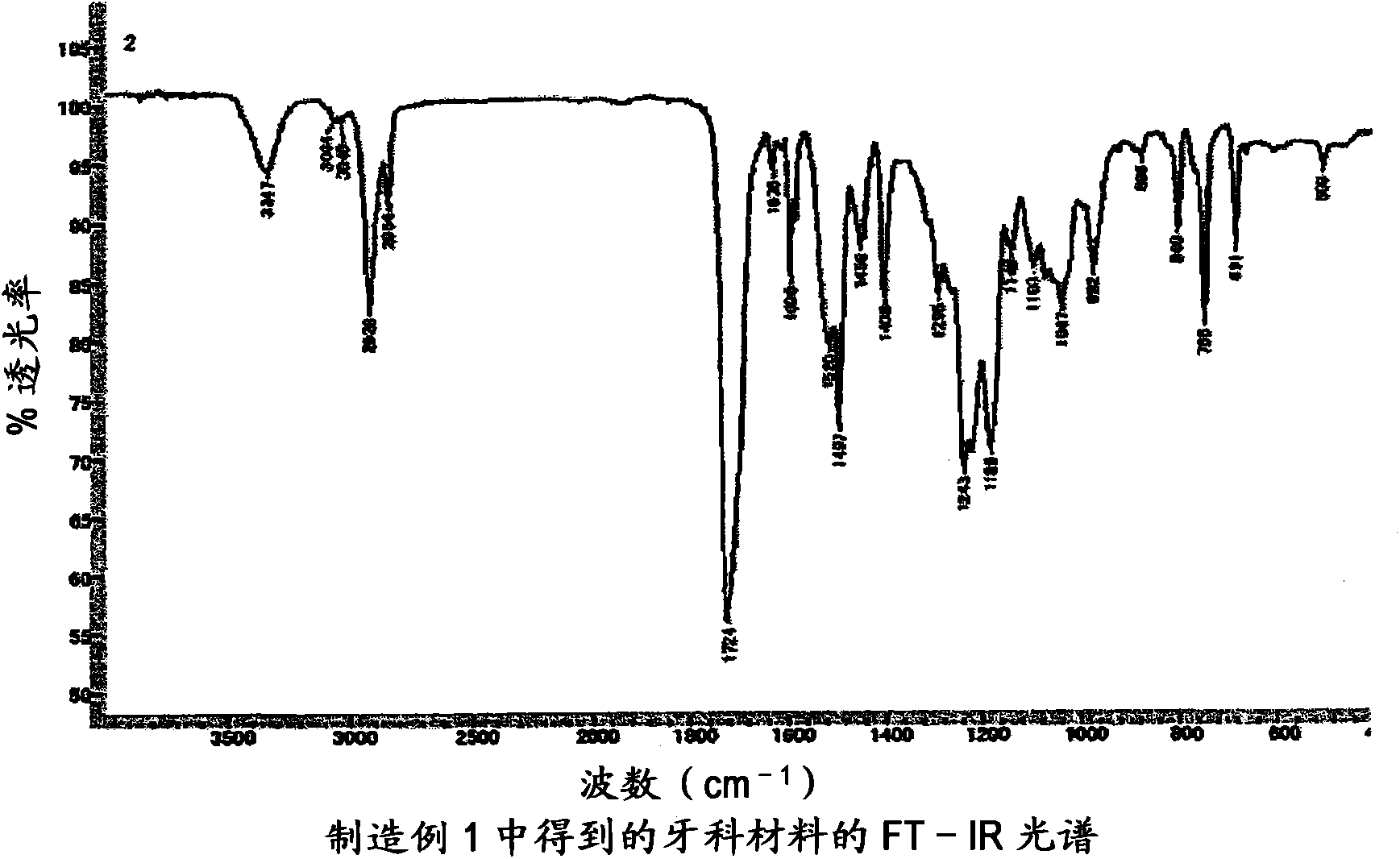

manufacture example 1

[0233] Add 111.1 g (0.5 moles) of 3-phenoxy-2-hydroxypropyl acrylate and 0.11 g of dibutyltin dilaurate (relative to hydroxyl-containing ( The weight of the meth)acrylic compound is 1000ppm), and the temperature is raised to 60°C. Next, when 65.6 g (0.25 mol) of diisocyanatocyclohexylmethane (hydrogenated MDI) was dripped over 0.5 hour, reaction temperature rose to 80 degreeC. After dripping all, reaction temperature was maintained at 80-90 degreeC, and reaction was performed for 10 hours. When the weight % of the hydrogenated MDI in the reaction product was measured, it was 0.00 weight%.

[0234] The product was discharged from the reactor to obtain 170 g of dental materials containing a urethane (meth)acrylic compound represented by the following formula.

[0235]

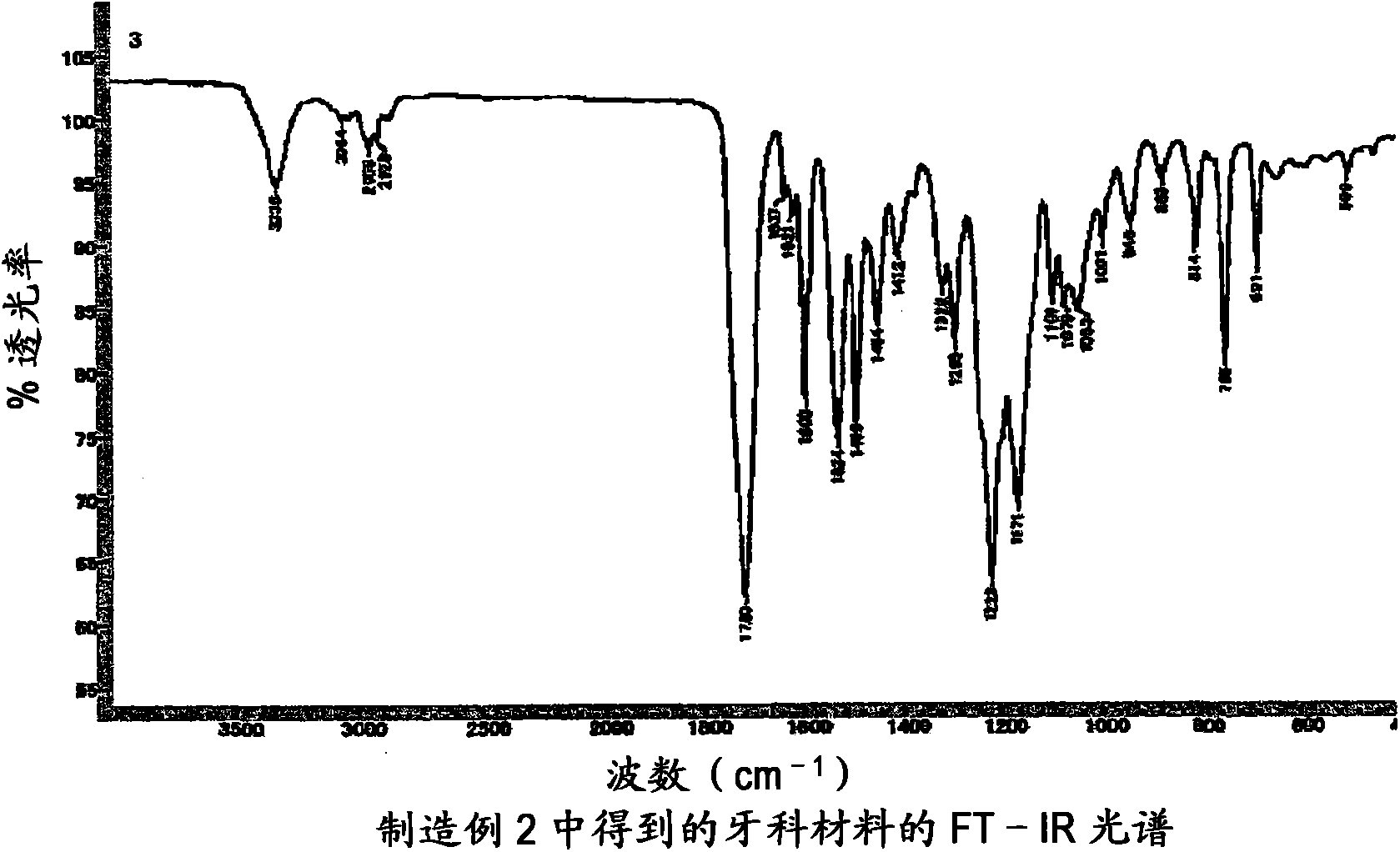

manufacture example 2~14

[0237] Using the hydroxyl group-containing (meth)acrylic compound and diisocyanate shown in Table 11 instead of 3-phenoxy-2-hydroxypropyl acrylate and hydrogenated MDI described in Production Example 1, the same procedure as in Production Example 1 was carried out. Synthetic manipulations to obtain dental materials comprising various urethane (meth)acrylic compounds.

[0238] [Table 11]

[0239]

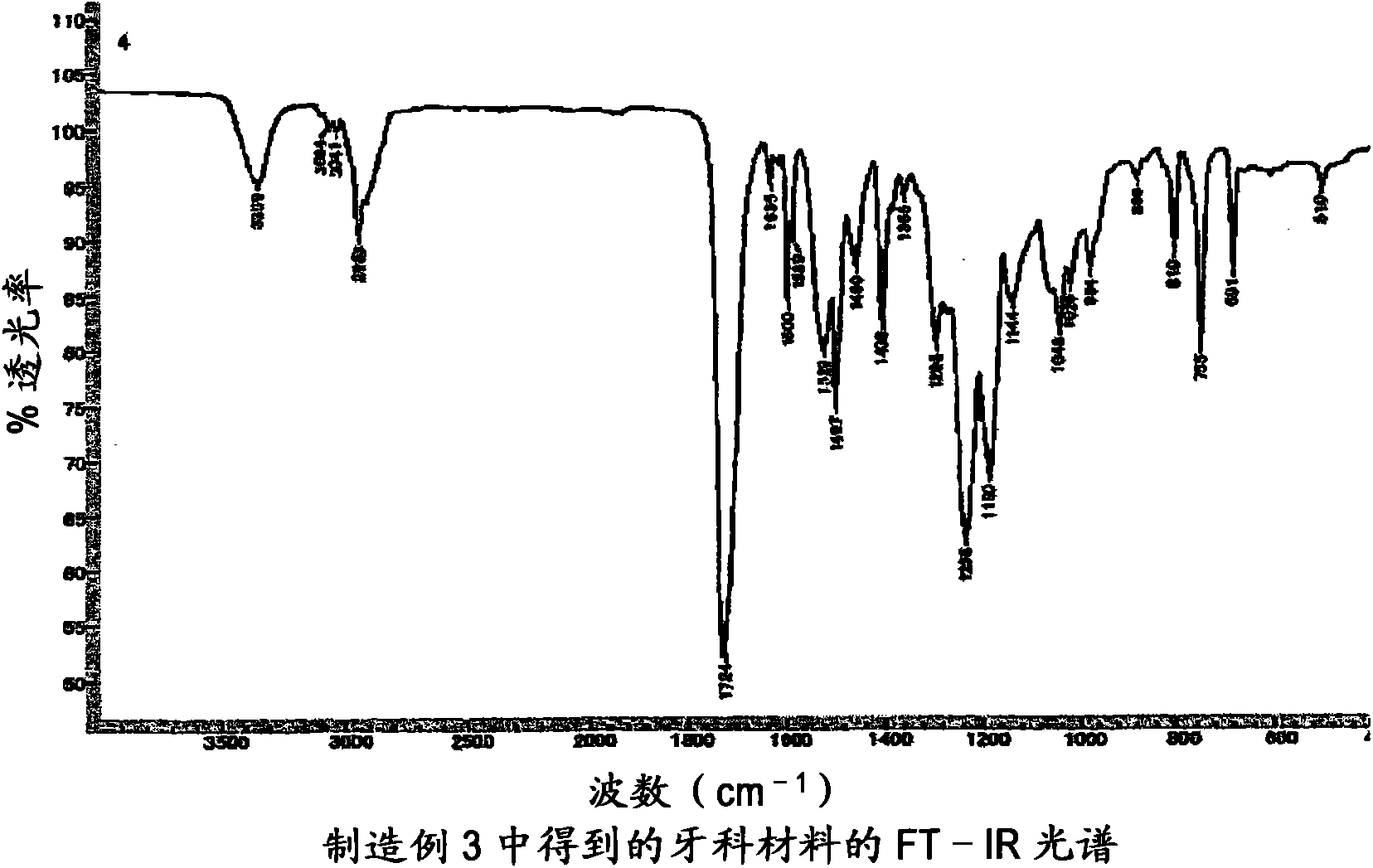

manufacture example 15

[0241] 14.4 g (0.2 mol) of acrylic acid and 0.5 g (1.7 mmol) of tetrabutylammonium bromide as a catalyst were added to a 300 ml four-necked bottle equipped with a stirring blade, a thermometer, and a reflux tube, and the temperature was raised to 60°C. Then, 55.3 g (0.2 mol) of 4-nonylphenyl glycidyl ether was dripped over 0.7 hours, and the reaction temperature rose to 65 degreeC. After dripping all, reaction temperature was maintained at 90-100 degreeC, and reaction was performed for 12 hours. After the reaction, the reaction solution was cooled to room temperature, and 200 ml of toluene was added. The obtained toluene solution was transferred to a 500 ml separatory funnel, and washed with distilled water until the pH of the aqueous layer reached neutrality. After washing with water, toluene was distilled off from the toluene layer with an evaporator to obtain 60.6 g of 2-hydroxy-3-(4-nonylphenoxy)propyl acrylate (yield 87%).

[0242] Add 52.3 g (0.15 mol) of 2-hydroxy-3-(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com